Establishing mdc-360c control loop parameters, Stablishing, Mdc-360c – INFICON MDC-360C Thin Film Deposition Controller User Manual

Page 101: Ontrol, Arameters, Table 6-1 default and range for pid parameters -3

MDC-360C DEPOSITION CONTROLLER

Tuning the MDC-360C Control Loop

6-3

gone 48 miles because of some traffic earlier on. Our Integral error is 2 miles. If

we want to get back on schedule we need to speed up a bit. If schedule is very

important to us, we will speed up a lot to get back on schedule fast. If schedule is

not important at all we will maintain our speed. The Integral Time constant

instructs the controller on how much attention to pay to the schedule. If we don’t

care what happened in the past and we want zero rate error right now, we don’t

want any Integral feedback. To accomplish that we set the Integral Time constant

to its maximum value, which tells the controller to ignore any past error unless it

lasts for a very long time.

6.3

ESTABLISHING MDC-360C CONTROL LOOP PARAMETERS

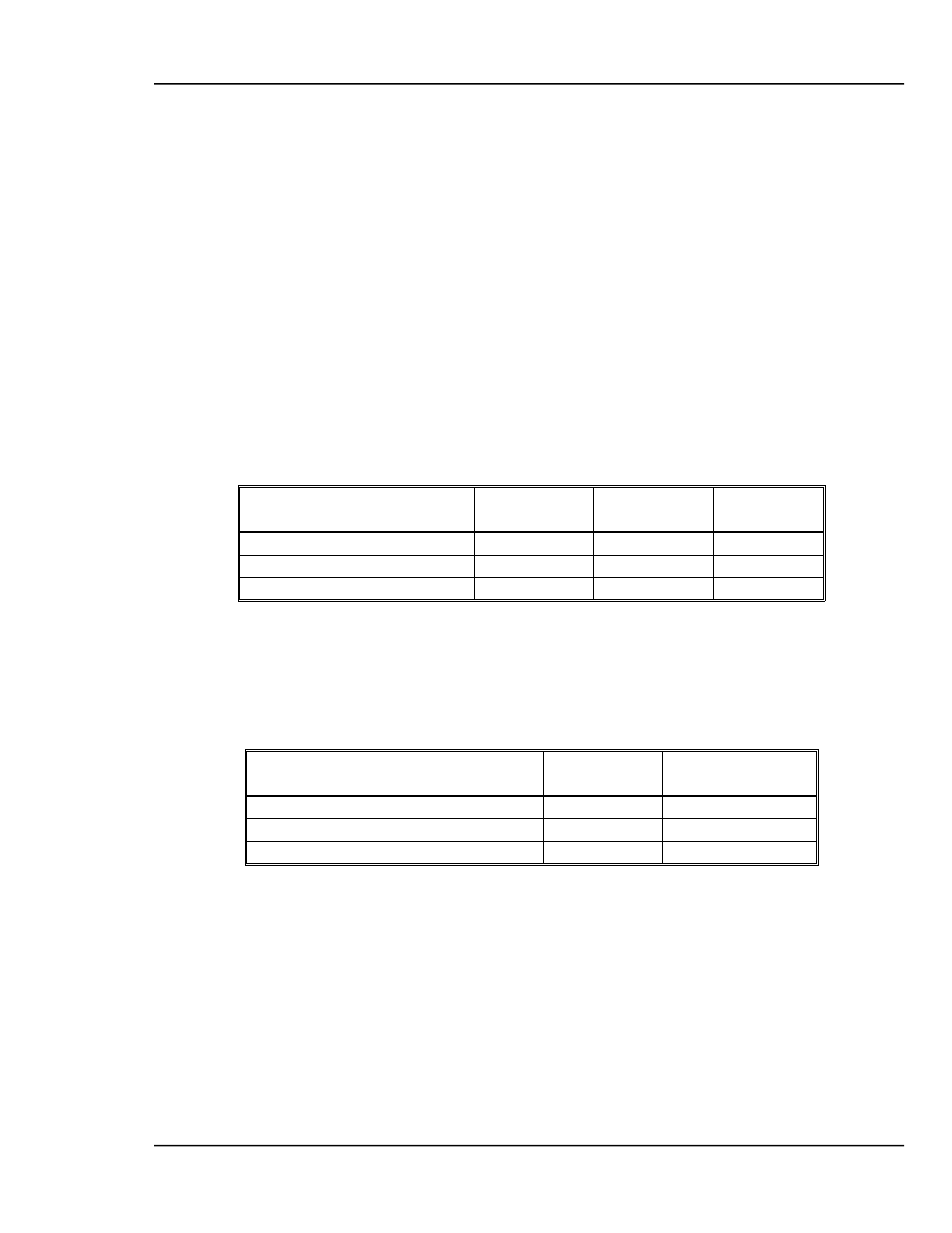

As explained above, the MDC utilizes three control loop parameters referred to as

PID parameters; Proportional gain, Integral Time constant and Derivative Time

constant to provide for optimization of the control loop. The MDC provides

default values for each of these parameters.

Parameter

Minimum

value

Maximum

value

Default

value

Proportional gain

1

9999

1000

Integral time constant, sec.

0

99.9

99.9

Derivative time constant sec.

0

99.9

0.0

Table 6-1 Default and Range for PID Parameters

The following table lists some recommended PID values for different types of

deposition sources. These values represent a good starting point and in some

cases may not need to be further modified.

Parameter

Electron

Beam Gun

Filament Boat

Proportional gain

2000

600

Integral time constant, sec.

99.9

99.9

Derivative time constant sec.

25.0

75.0

Table 6-2 Suggested PID Starting Values for Different Sources

In the MDC-360C, the PID parameters are defined at the material level because

different materials often require different PID settings even though they may be

deposited from the same source. Therefore it is usually necessary to establish the

PID parameters for every each material and deposition source.

The first step in setting the PID parameters for a new material or source is to enter

the recommended starting values listed above. Be sure and choose the PID values

for the type of source you're using. Next, create a dummy process with the first

layer set for the new material. Start and abort the dummy process to load the new

material as the active material. You should now see the material's name in the top

line of any Status Screen. Next, open the shutter and put the MDC-360C in the