Chapter 1 introduction, 1 introduction, Chapter 1 – INFICON Front Load Single Sensor User Manual

Page 11

1 - 1

PN

07

4-

15

6N

Front Load Single and Dual Sensors Operating Manual

Chapter 1

Introduction

1.1 Introduction

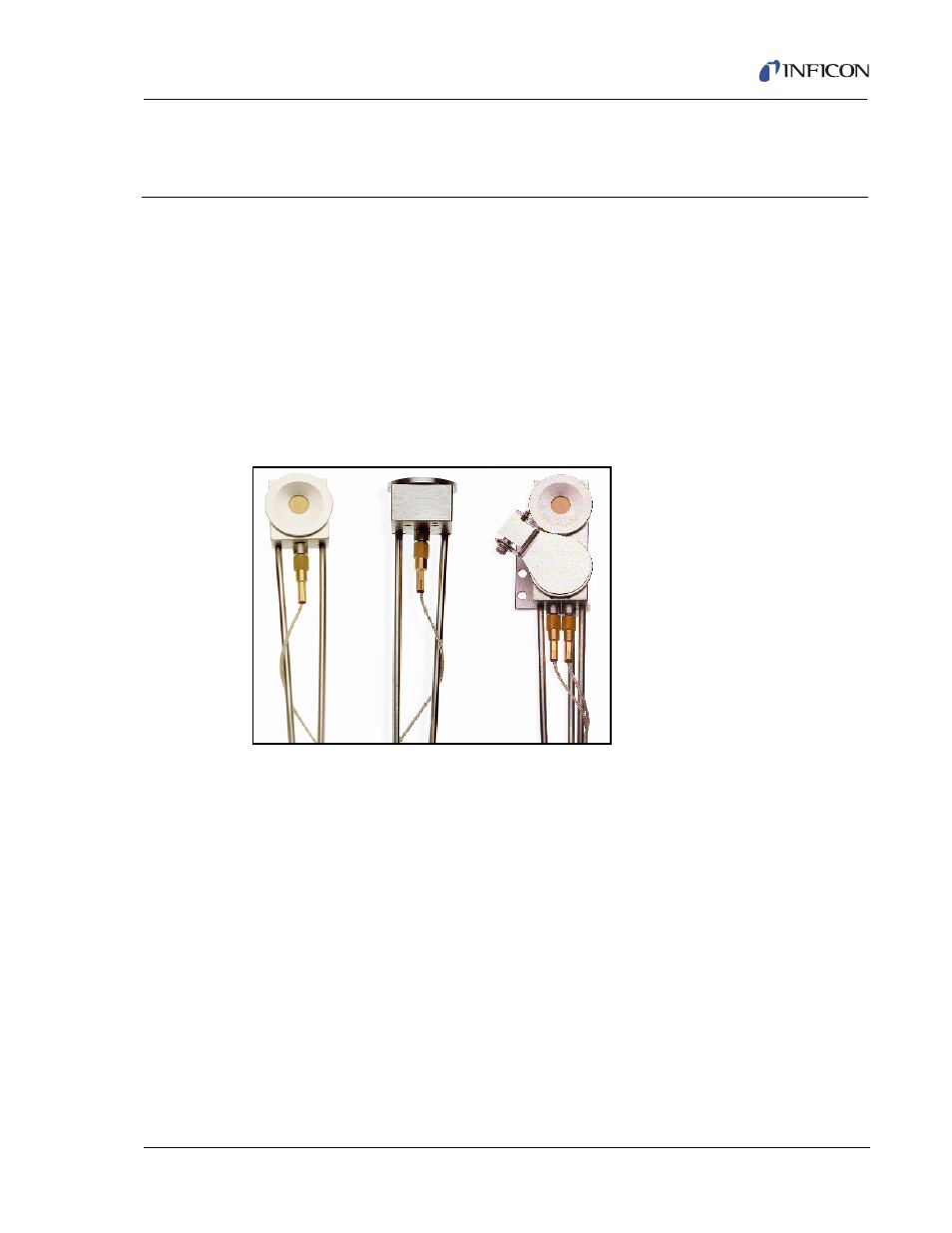

INFICON Front Load Sensors (see

) offer proven reliability and durability

combined with excellent thermal stability. The front load design allows for easy

insertion of the crystal holder in applications lacking sufficient room for side access.

Because they are assembled mechanically rather than soldered, parts can

conveniently be replaced in the field. Sensors can be ordered individually or in a

sensor and feedthrough combination that can be either welded or assembled with

Ultra-Torr® O-ring compression fittings.

Figure 1-1 Front Load Sensors

The Front Load Sensor comes in two styles: Single or Dual.

The Front Load Single Sensor comes in two sensor configurations:

Standard or Right Angle (Compact).

Standard configuration—installed from the side or bottom of the chamber, with

the cooling tubes aligned parallel to the crystal face.

Right Angle configuration—installed through the top of the vacuum system,

with the water cooling tubes aligned perpendicular to the crystal face.

For the Front Load Dual Sensor, a Standard configuration (i.e., waterlines parallel

to the crystal face) is available.

Optionally, single sensors can be ordered with a pneumatically driven crystal

shutter to protect the crystal during source warm up, or when the sensor is not used

during deposition of an alternate material, or to extend crystal life when used

with RateWatcher™ or rate sampling.

NOTE: Crystal shutters are standard on Front Load Dual Sensors.