Flint & Walling CPJS Shallow Well User Manual

Page 8

8

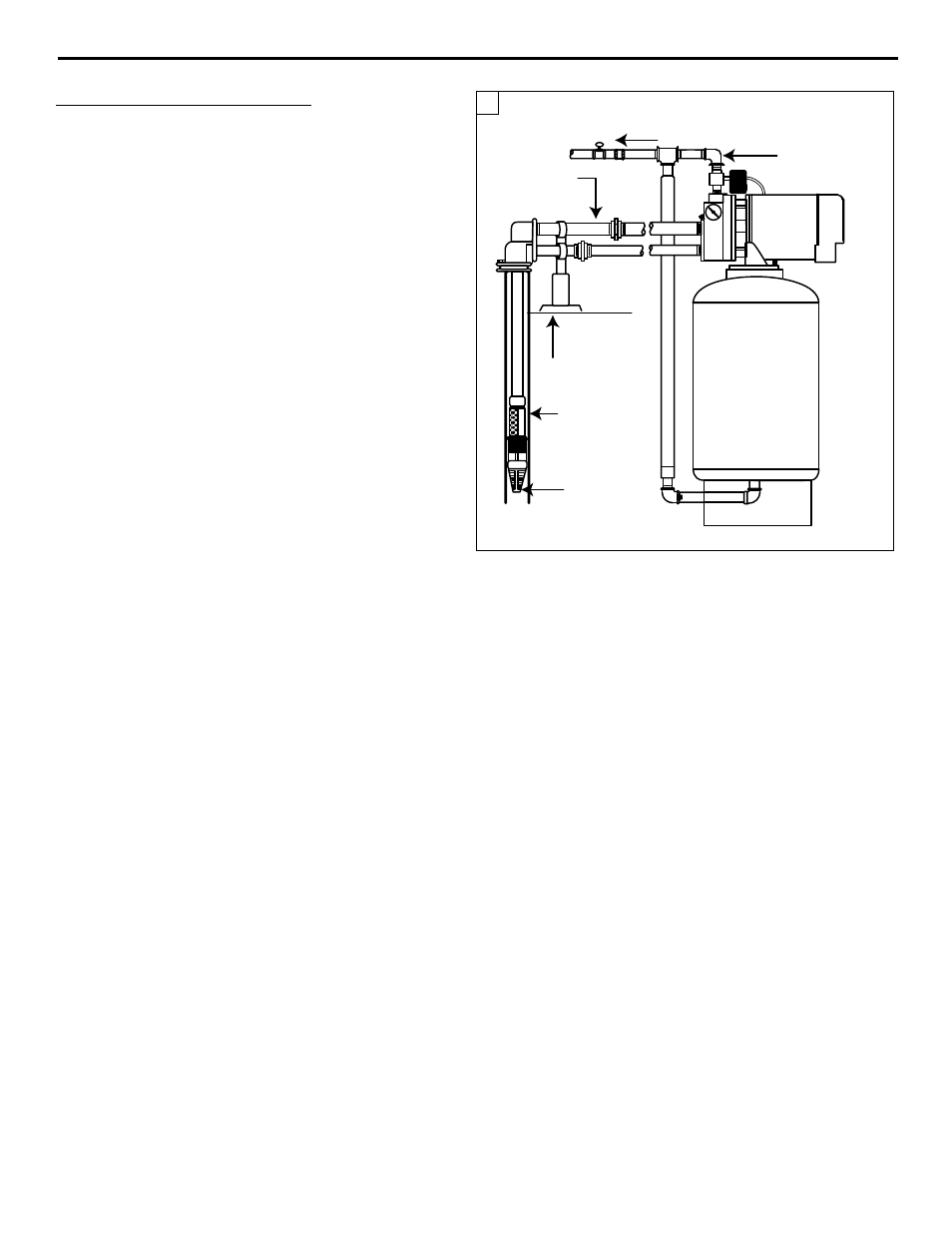

Deep Well (Single Pipe System)

Application - Where pumping water level is greater than 25

feet and inside diameter of well is 2, 2-1/2 or 3 inches. (

Fig

1)

On single pipe deep well installations, clean, sound well

casing must be used to give a tight seal.

NOTE: This application requires a well adapter for the top

of the well.

NOTE: Pre-soak packer leathers for approximately two

hours before installation.

1. Attach foot valve directly to bottom of ejector assembly.

Ejector must be submerged 10 to 15 feet below

pumping water level and the foot valve must be at least

five (5) feet from bottom of well.

2. Attach foot valve and packer ejector to suction pipe

(presoak packer leathers for approximately two (2)

hours). Push the assembly down the well. Some force

may be required to push the ejector down the casing.

3. As each section is lowered, check for leaks by pouring

water into the suction pipe.

4. Attach well adapter to suction pipe, lower over casing

top and tighten adapter flange.

5. If no leaks are found, proceed to

WELL TO PUMP

CONNECTION (SUCTION PIPE) using piping of

the same diameter as the suction pipe (1-1/4”) and

pressure pipe (1”) tappings of the pump. For long offset

distances, see Table B for the proper pipe size.

6. Unions in suction and discharge piping near pump

and well will aid in servicing. Be sure to leave enough

surrounding room so that wrenches can be used easily.

IL0209

3/4 or 1 in.

Discharge

Pipe

Suction

Pipe See

Table B

Discharge

to Home

Pipe

Support

Foot Valve

2 in. ID Well

1

INSTALLING PIPING IN WELL