Flint & Walling CPJS Shallow Well User Manual

Page 21

21

PUMP PRIMING & STARTUP

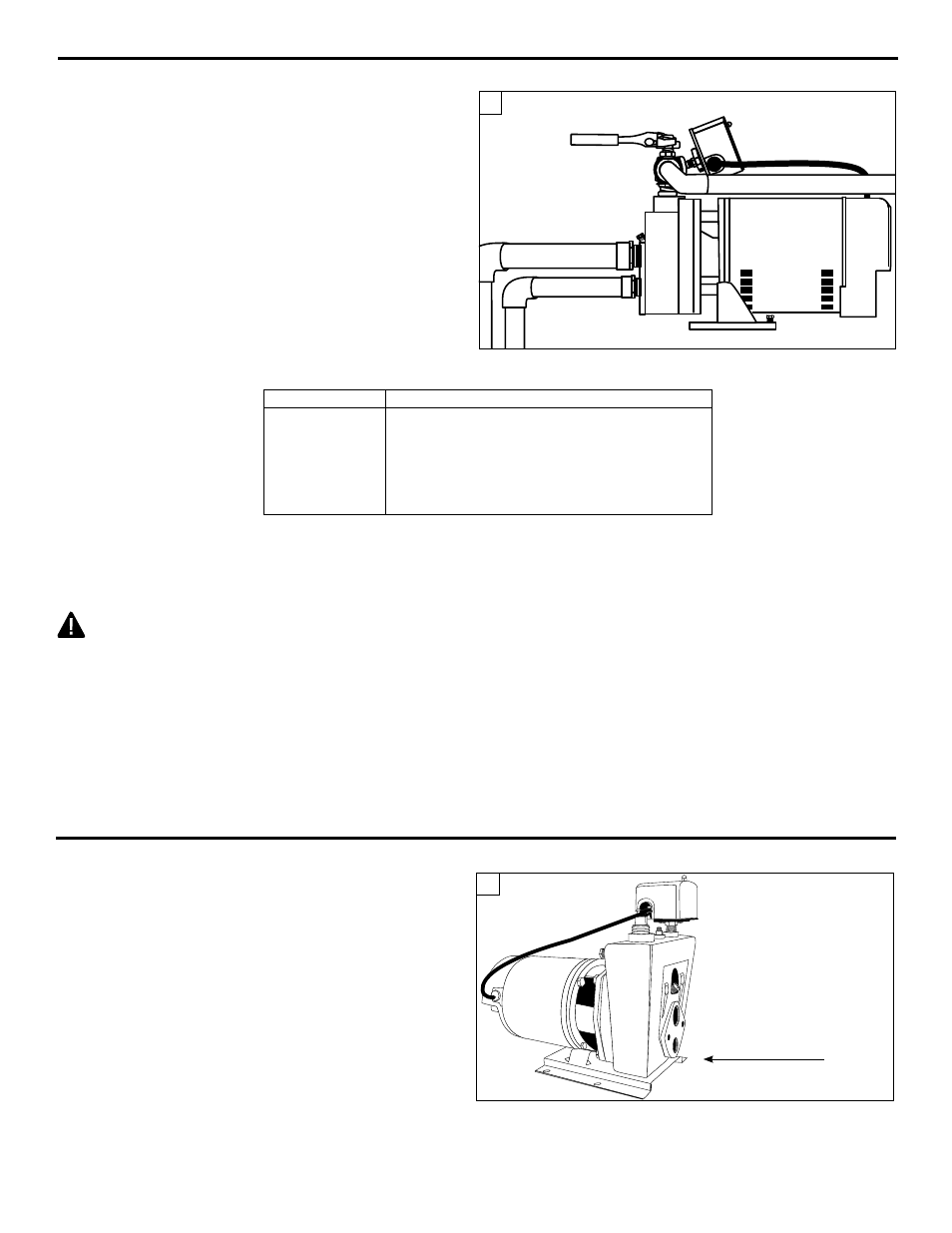

5. With pump operating at high pressure, open two or more

faucets and slowly unscrew the flow control screw until

maximum flow is obtained. This steady pressure will be

minimum operating pressure and should agree with the

pressure shown below. The flow control screw diverts

the proper amount of water to operate the ejector. (

Fig.

5)

The correct control valve setting will depend on the type of well installation and pressure switch setting for the particular

pump.

NOTE: Flow control is not required for shallow well applications.

IMPORTANT: If the pump fails to prime within five minutes:

Turn power off at the breaker box. Look for leaks or a milky color in the discharged water, which indicates an air leak. Re-

prime if necessary, following steps 1 through 5 above. Reset breaker at the breaker box. All connections must be water

and air tight in order for pump to operate.

IL1409

5

AVERAGE OPERATING PRESSURE CHART 7

HP

Pressure Setting

1/3

1/2

3/4

1

1-1/2

24 PSI

27 PSI

38 PSI

46 PSI

53 PSI

CARE AND MAINTENANCE

MAINTENANCE

Lubrication

The pumps and motors require no lubrication. The ball

bearings of the motor have been greased at the factory

and under normal operating conditions should require no

further greasing.

Freezing

1. Drain the entire system if there is danger of freezing.

A drain plug is provided at the bottom of the pump

case for this purpose. (Fig. 1)

IL0192

1

PREVENT PUMP

DAMAGE!

Remove plug in

freezing weather