Flint & Walling CPJS Shallow Well User Manual

Page 7

7

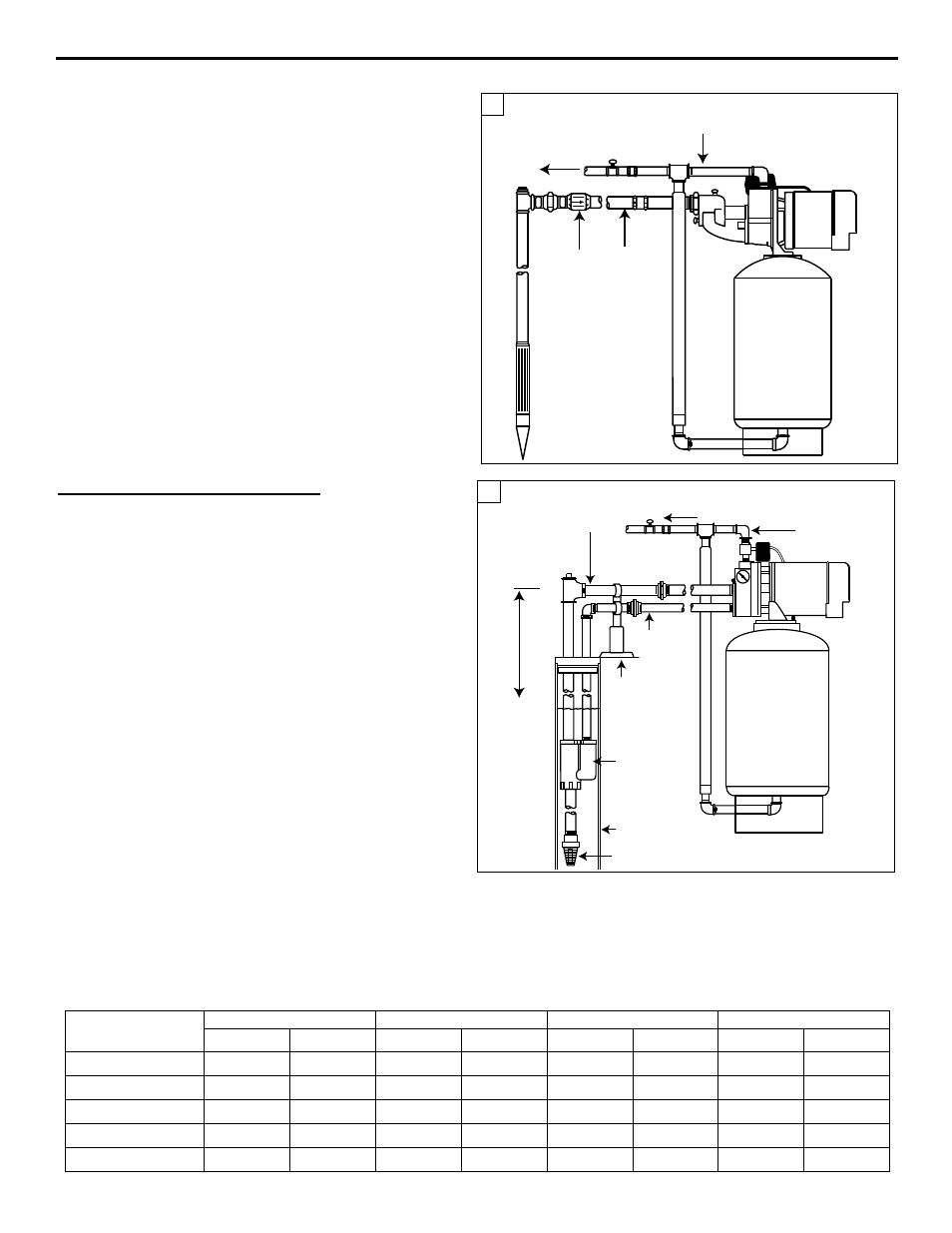

INSTALLING PIPING IN WELL

IL1188

3/4 or 1 in.

Discharge Pipe

1-1/4 in.

Suction

Pipe

Discharge

to Home

Check

Valve

2

RECOMMENDED SUCTION PIPE SIzES FOR SHALLOW WELL PUMP CHART 5

Motor

HP

Vertical Piping Size

Length of Offset from Well

0-20’

20-100’

100-200’

200-400’

1/3

1’

1”

1-1/4”

1-1/2”

2”

1/2

1”

1”

1-1/2”

1-1/2”

2”

3/4

1-1/4”

1-1/4”

1-1/2”

2”

2”

1

1-1/4”

1-1/4”

1-1/2”

2”

2”

1-1/2

1-1/4”

1-1/4”

1-1/2”

2”

2”

When connecting a drive point (Fig. 2) a check valve must

be used in the suction line in place of a foot valve. For easy

priming connect the check valve as close to the well as

possible.

All piping from the well to the pump should slope slightly

upward with no sagging. Support suction pipe between

water source and pump. Unions in the suction line near

the pump and well will aid in servicing. Be sure to leave

enough room so that wrenches can be used easily.

Deep Well (Double Pipe System)

Where water level is greater than 25 feet and inside

diameter of well is four (4) inches or larger (Fig. 1).

1. Attach the foot valve to the ejector using a galvanized

steel or plastic nipple. Add enough 1 in. pressure pipe

and 1-1/4 in suction pipe to submerge ejector 10 to 15’

below pumping water level, making certain foot valve is

at least five (5) feet from bottom of well. If pressure pipe

and suction pipe of the same diameter are used, be sure

to identify them clearly so that they will be connected to

the proper tappings of the pump.

If a known well leak exists, replace nipple with 21 feet

of 1” tail pipe between the ejector and the foot valve.

This will provide a continuous source of water for the

pumping system.

2. Check pipe and foot valve for leaks by filling pipes with

water. A continuous loss of water indicates a leak in the

piping, foot valve or unions, and must be corrected.

3. If no leaks are found, proceed to

WELL TO PUMP

CONNECTION (SUCTION PIPE). For long offset

distances, see Table B for proper pipe size.

4. All piping from the well to the pump should slope slightly

upward with no sagging. Support suction pipe between

water source and pump. Unions in the suction line near

the pump and well will aid in servicing. Be sure to leave

enough room so that wrenches can be used easily.

IL1184

Water

Level

Suction

Lift

3/4 or 1 in.

Discharge

Pipe

Suction

Pipe See

Table B

Discharge

to Home

Pipe

Support

Foot Valve

Pressure

Pipe See

Table B

4 in. ID Well

Ejector

1

PIPE SIzES REqUIRED FOR OFFSET PIPING FOR DEEP WELL EJECTOR INSTALLATION TABLE B

Distance Well to

Pump

1/3 HP

1/2 HP

3/4 HP

1 & 1-1/2 HP

Suc.

Press.

Suc.

Press.

Suc.

Press.

Suc.

Press.

0-25’

1-1/4”

1”

1-1/4”

1”

1-1/4”

1”

1-1/4”

1”

25-50’

1-1/4”

1”

1-1/4”

1-1/4”

1-1/2”

1-1/4”

1-1/2”

1-1/4”

50-75’

1-1/4”

1-1/4”

1-1/4”

1-1/4”

1-1/2”

1-1/2”

1-1/2”

1-1/2”

75-100’

1-1/2”

1-1/4”

1-1/2”

1-1/4”

1-1/2”

1-1/2”

2”

1-1/2”

100-150’

1-1/2”

1-1/4”

1-1/2”

1-1/2”

2”

1-1/2”

2”

2”