8 repair, 9 accessories, 10 eliminating malfunctions – Festo DGC-8 ... 63-... User Manual

Page 8: 11 technical data

Lubricating the guides of types

G and GF:

• Lubricate the guide rail if it no longer has a layer of grease, but at the latest:

– every 3000 km or every 3 years. Grease type: LUB-KC1 (for DGC-

8-G/GF)

– every 1000 km or every 2 years. Grease type: LUB-E1 (for DGC-...-G/GF-

H1)

• Note that lubrication must be undertaken more often:

– if the environment is dusty and contaminated

– with work strokes of

< 50 mm

– ambient temperatures

> 40°C.

The remaining sizes of types G/GF do not require any maintenance (relubrication

however is permitted).

Lubricating the guide of type

KF:

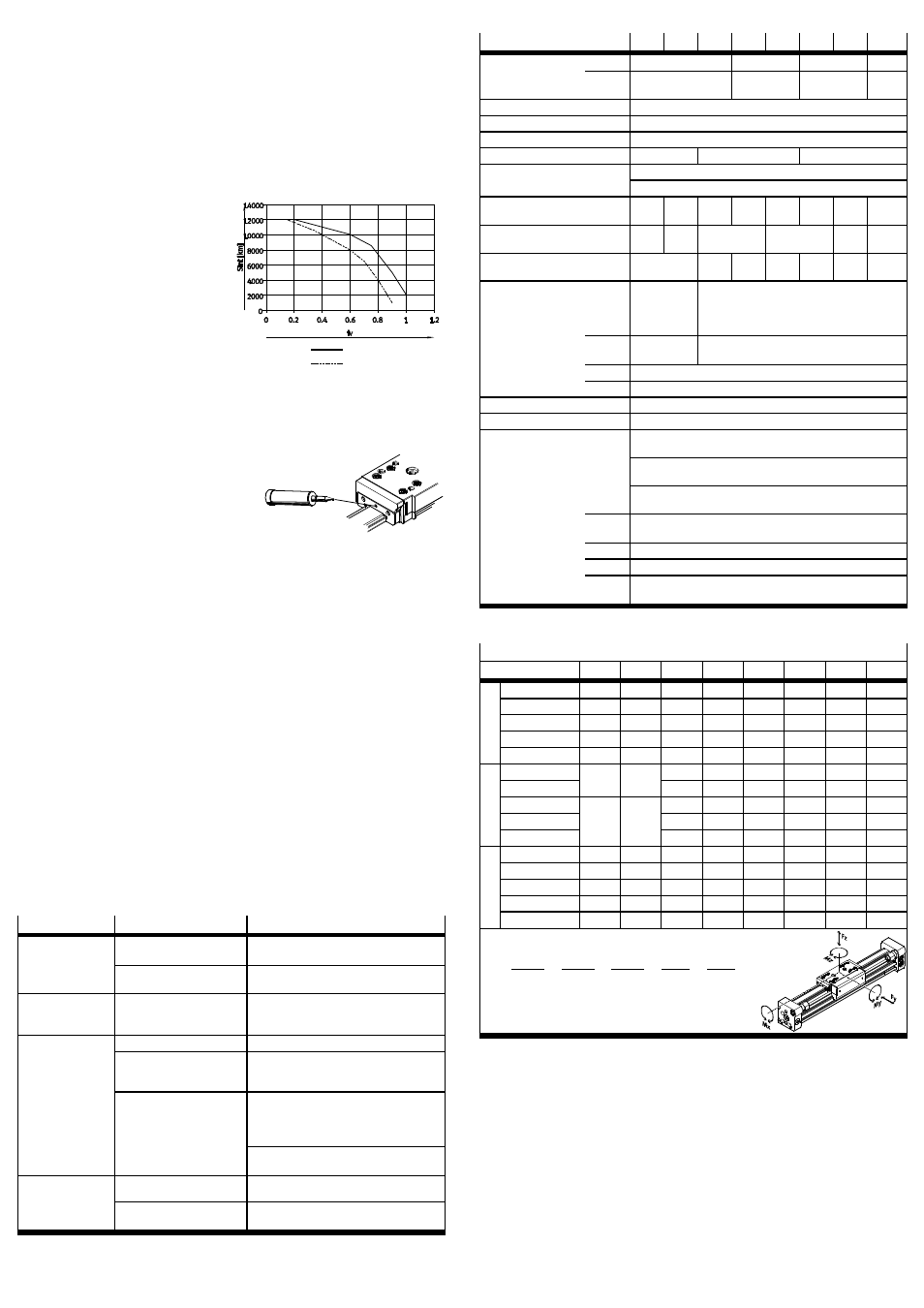

The lubrication intervals S

int

depend on

the load of the guide.

1. Calculate the load comparison factor

f

v

with the aid of the formula for

combined loads (

Technical data)

and determine the lubricating

interval S

int

from Fig. 24.

• Always lubricate the DGC at the

latest every 3 years (every 2 years

for the DGC-...-KF-...-H1).

Fig. 24

DGC

DGC-H1

• Note that lubrication must be undertaken more often:

– if the environment is dusty and contaminated

– with work strokes of

< 50 mm or > 2000 mm

– at speeds of

> 2 m/s

– in ambient temperatures of

> 40°C.

2. Lubricate the roller bearing through

the holes on both sides of the slide.

For this purpose use a grease gun

with a pointed nozzle or alternatively

a disposable syringe with needle.

Fig. 25

Permitted grease types:

DGC-8/12-KF:

LUB-LG0

DGC-18 … 63-KF:

LUB-RN2

DGC-8 … 63-KF-H1:

ELKALUB VP 874 (from Chemie-Technik)

• Push the slide backwards and forwards during lubrication.

Otherwise the grease cavities will not be filled to an equal extent.

Alternatively, Festo offers a service inspection which includes lubrication.

Otherwise the DGC does not require any maintenance.

8

Repair

• Recommendation: Return the product to our repair service for overhaul.

This ensures that special attention will be paid to the necessary fine adjust-

ments and inspections.

• Information on spare parts and aids can be found under:

www.festo.com/spareparts

Replacing cushioning elements:

• Note the section “Accurate adjustment of the stroke” in the chapter “Commis-

sioning”.

9

Accessories

Please select the appropriate accessories from our catalogue

www.festo.com/catalogue/DGC

10

Eliminating malfunctions

Malfunction

Possible cause

Remedy

Uneven movement

of the slide

One-way flow control valve

not fitted correctly

If possible reduce the exhaust

(not the supply air)

Guide rail not greased

Lubricate guide rails in accordance with

chapter “Care and maintenance”

Faults in position

scanning

Ferritic parts in the vicinity

of the proximity sensor

Use parts made of non-magnetic materials

or observe minimum distances

(

5.3. Installing the electric components)

Heavy leakage

Cylinder is distorted

Fasten the cylinder to a flat base.

Seal worn

Replace worn parts:

– Yourself with wearing parts kit

– By returning to Festo for repairs

Sealing band pressed in/

sucked in

When the linear drive is unpressurised,

move the slide twice manually through the

entire stroke (if necessary, push fixed stops

into the end position)

Avoid vacuum in the piston chamber

(e.g. move the unpressurised slide slowly)

Cylinder does not

reach the desired

speed

Air volume not sufficient

– Select tubing with larger diameter

– Switch volume upstream

High friction or

counteracting force

Observe maximum limits

Fig. 26

11

Technical data

DGC-

8

12

18

25

32

40

50

63

Pneumatic

connection

DGC

M5

G

Á

G

¼

G

Å

DGC-N

M5 suitable for

10-32 UNF

Á NPT

¼ NPT

Å

NPT

Mode of operation

Double-acting

Mounting position

Any

Operating medium

Compressed air in accordance with ISO8573-1:2010 [7:-:-]

Operating pressure

[bar]

2.5 … 8

2 … 8

1.5 … 8

Ambient temperature

[°C]

–10 … +60

+5 … +60 (DGC-

8-G)

Theoretical force

at 6 bar

[N]

30

68

153

295

483

754

1178

1870

Speeds (min ... max)

[m/s]

0.15

… 1

0.1

… 1.2

0.05

… 3

0.04

… 3

0.03

… 3

0.02

… 3

Cushioning length

PPV

[mm]

–

16.5

15.5

17.5

29.5

29.8

31.1

Cushioning

P

Flexible

cushioning

rings/pads

at both ends

–

PPV

–

Pneumatic cushioning, adjustable at both

ends

YSR

Shock absorber, hard characteristic curve

YSRW

Shock absorber, progressive characteristic

Max. energy

For diagrams, see catalogue specifications

Note on materials

KF

Free of copper and PTFE

Materials

Scraper, band reverser,

cover:

Polyacetal/polyamide

Piston seal, cushioning seal,

sealing band, cover band:

Polyurethane

Stops:

Steel, corrosion resistant/

coated

G

End cap, cover, slide:

Aluminium, coated/

polyamide

GF

Slide:

Aluminium, anodised

G/GF

Cylinder profile, guide rail:

Aluminium, anodised

KF

Guide rail, slide:

Steel, corrosion resistant/

coated

Fig. 27

Permitted force and torque loading

DGC-

8

12

18

25

32

40

50

63

G

Fymax

[N]

150

300

70

180

250

370

480

650

Fzmax

150

300

340

540

800

1100

1600

2000

Mxmax

[Nm]

0.5

1.3

1.9

4

9

12

20

26

Mymax

2

5

12

20

40

60

150

150

Mzmax

2

5

4

5

12

25

37

48

GF Fymax

[N]

–

–

440

640

900

1380

1500

2300

Fzmax

540

1300

1800

2000

2870

4460

Mxmax

[Nm]

–

–

3.4

8.5

15

28

54

96

Mymax

20

40

70

110

270

450

Mzmax

8.5

20

33

54

103

187

KF Fymax

[N]

300

650

1850

3050

3310

6890

6890

15200

Fzmax

300

650

1850

3050

3310

6890

6890

15200

Mxmax

[Nm]

1.7

3.5

16

36

54

144

144

529

Mymax

4.5

10

51

97

150

380

634

1157

Mzmax

4.5

10

51

97

150

380

634

1157

f

v

=

|Mx|

Mx

max

+

|My|

My

max

+

|Mz|

Mz

max

+

|Fy|

Fy

max

+

|Fz|

Fz

max

≤ 1

Formula for combined loadings:

Fig. 28