ETC Sensor3 CE (ESR3) Rack User Manual

Page 22

14

Sensor3 CE Rack (ESR3) Installation Manual

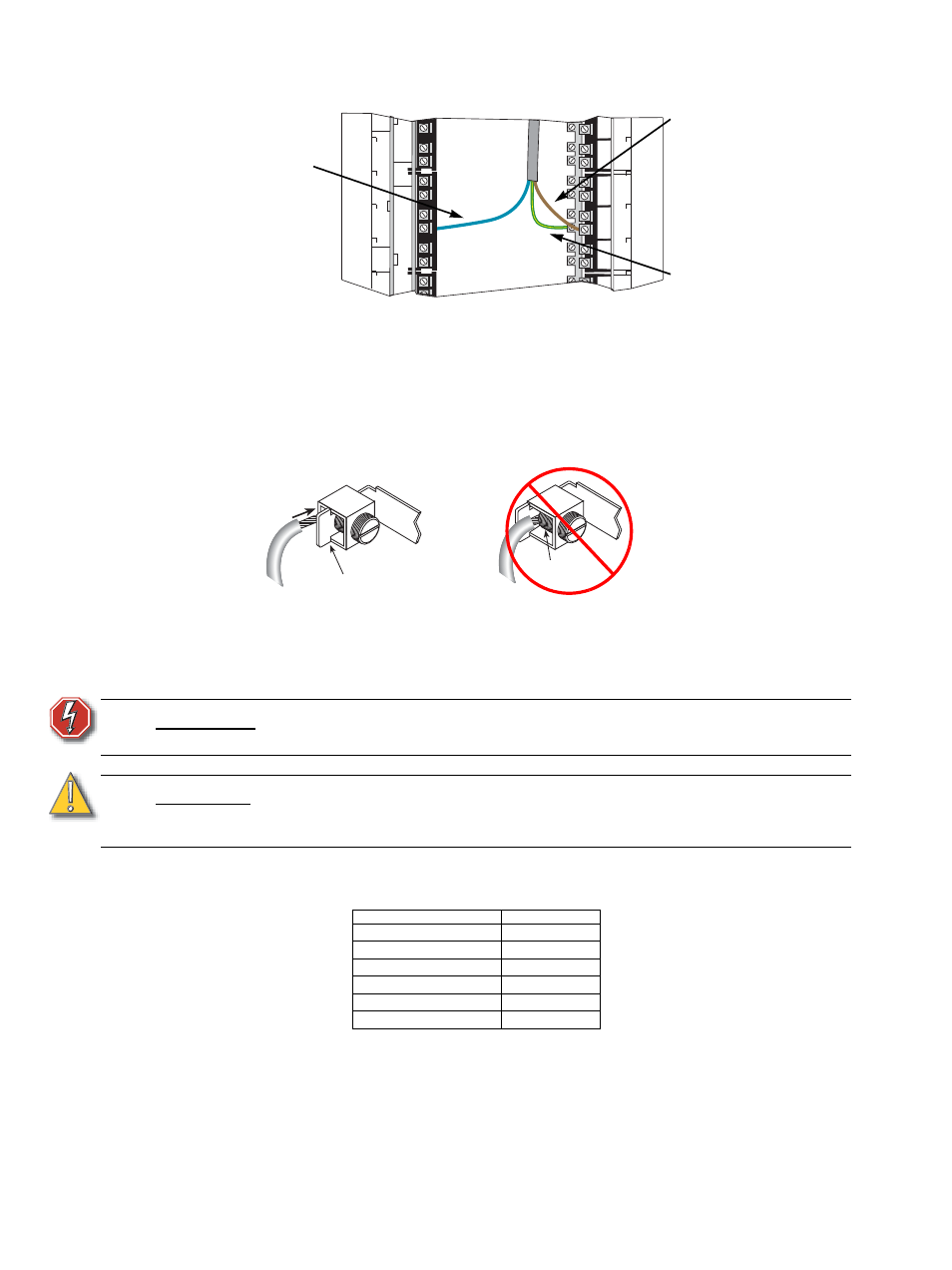

that phase, neutral and earth can be corrected to the relevant lugs as shown.

Step 3:

Fit load earth wires into the earth lugs as shown below and torque to the

recommended value from Table 1.

•

Insert the wire under the pressure plate and tighten it onto the wire with the

screw. Do not clamp the wire directly under the screw.

Figure 13: Connecting lug wires

Step 4:

Fit load neutral wires into the neutral lugs in the same manner and torque to the

recommended value.

Step 5:

Fit load phase wires into the phase lugs in the same manner and torque to the

recommended value.

Step 6:

Tighten all load connections to the torque specified in the table below.

Table 1: Lug torque values

W A R N I N G :

If any wire splices are required (none are recommended), they must be

made with a crimp-style butt-splice. Terminal block is NOT acceptable.

C A U T I O N :

To prevent interference with cooling airflow, do not run load wires from one rack

through a different rack. See

Sealing Rack Air Leaks, page 28

for more

information.

Cable size

Torque (Nm)

1.5mm

2

4.0 Nm

2.5mm

2

4.0 Nm

4.0mm

2

4.0 Nm

6.0mm

2

4.5 Nm

10mm

2

4.5 Nm

16mm

2

5.0 Nm

Figure 12: Load cable connection to lugs

Load Neutral (blue

wires) are landed on

load neutral lugs

attached to the main

neutral bus plate

Each dimmer’s load

lug set is at the same

height.

Load Phase

(brown wire)

Load Earth

(green wire with

yellow stripe)

The Right way

Insert the wire between the pressure plate and

the back of the lug and clamp the plate on top of

the wire.

The Wrong way

Don’t clamp the wire on top of the

pressure plate with the lug screw.

Pressure Plate

Lug Screw