Instructions for vertical splicing, Bar-to-bar) – ERICO CADWELD for Rebar Splicing System User Manual

Page 6

4

www.erico.com

Instructions For Vertical Splicing

(Bar-to-Bar)

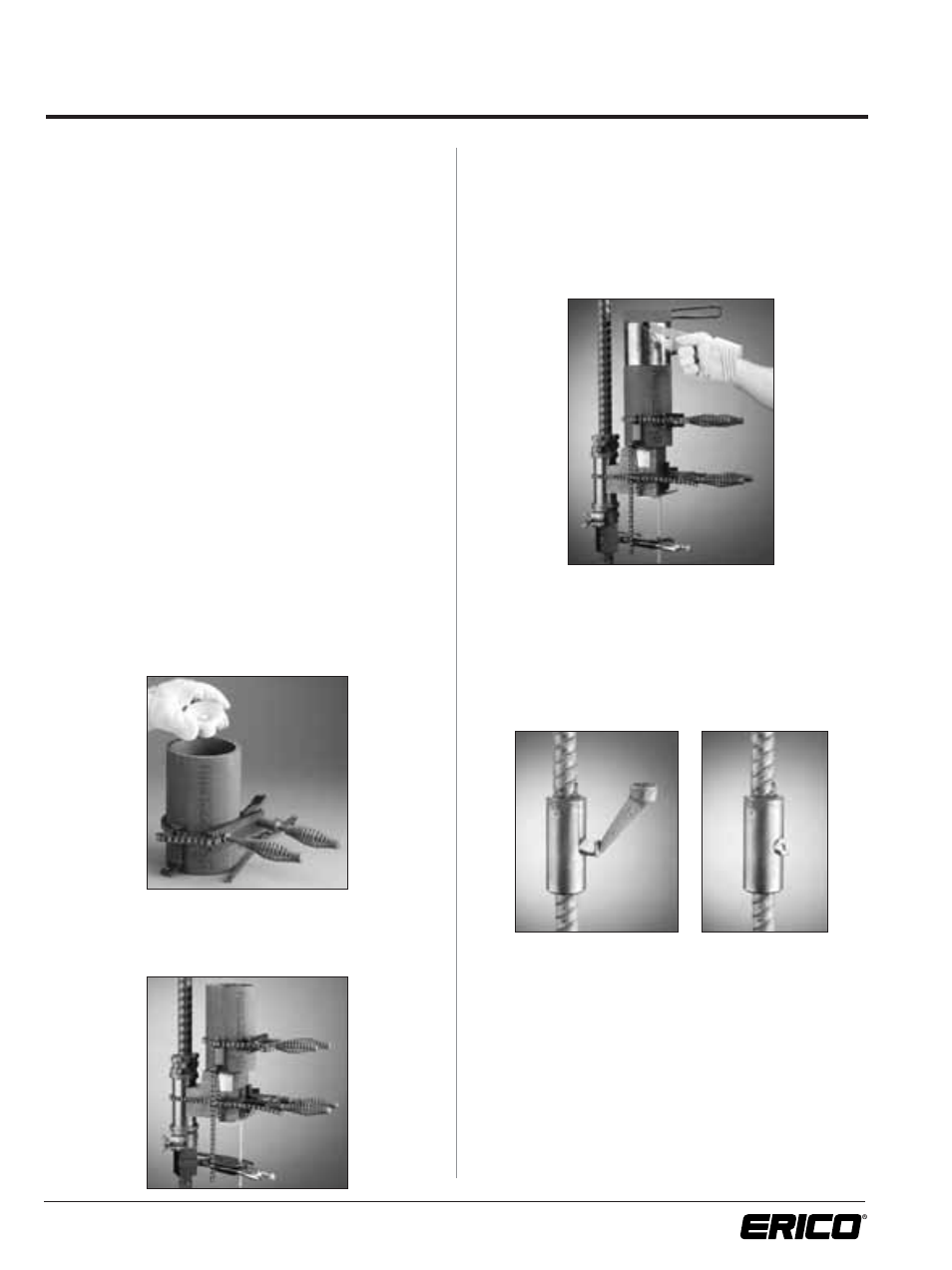

9. With pouring basin frame handles unlocked and pouring

basin slightly open, place the pouring basin around the

ceramic insert and against the splice sleeve. Close pouring

basin frame handles and lock. Place chain around the

sleeve and finger tighten thumb nut. Be sure to support

the pouring basin while securing chain to prevent

unseating of the sleeve against the bottom packing.

Adjust “T” shaped support rod against bottom of pouring

basin. Support rod should just touch and support levelled

pouring basin DO NOT force pouring basin up.

NOTE: A crucible should not be reused until allowed to

cool for 15 minutes or more. If more frequent use

is desired, several crucibles complete with frames

should be used alternately to allow sufficient cooling

time. Clean crucible thoroughly inside. Empty the

crucible completely, see Note 15 & 16 on this page for

additional information. DO NOT use a wire brush.

10. Place crucible ceramic insert assembly in bottom of

crucible. All crucibles use the same ceramic insert.

11. The crucible ceramic insert assembly is supplied with a

steel disk pre-installed into it as a one-piece assembly.

If the steel disk is not present in the ceramic insert,

place the steel disk on the crucible ceramic insert and

check for proper seating. Remix bag of CADWELD

®

filler

material and fill crucible according to the instructions on

page 7.

12. Position crucible on the pouring basin and secure the

tiedown chain, keeping it just loose enough to allow

swivelling of the crucible without tipping.

13. Open the starting material container. Evenly distribute

the starting material over the filler material in the crucible,

saving a small amount to be placed on the tab of the

crucible extension. Place the crucible extension on the

crucible and put the remainder of starting material on

the tab. Place the crucible cover on the extension.

Standing off to the side of the opening and up wind,

ignite the starting material on the tab.

14. Keep the tiedown chain secured at all times.

Immediately after the sleeve has filled, slowly swivel

the crucible back and forth to break the slag between

the base of the crucible and top of the pouring basin.

Repeat after 15 or 20 seconds as necessary.

After the slag has solidified, release the tiedown chain

and remove the crucible. All other parts can then be

removed.

15. Clean the crucible by turning upside down and placing

a metal rod (#5 [16mm] rebar) against the ceramic and

lightly tapping the rod end to discharge the slag and

ceramic into a suitable waste container.

16. Break off riser with hammer. Clean slag from crucible

and pouring basin as soon as possible to promote cooling.

Use a whisk broom, rag or wooden wedge for cleaning.

Do not use a wire brush. Cover and crucible extension

need not be cleaned every time.

NOTE: Clean flash or debris from all mating surfaces as debris

can cause springing of the equipment clamps and hinges.