Additional instructions for b-series – ERICO CADWELD for Rebar Splicing System User Manual

Page 14

12

www.erico.com

Additional Instructions For B-Series

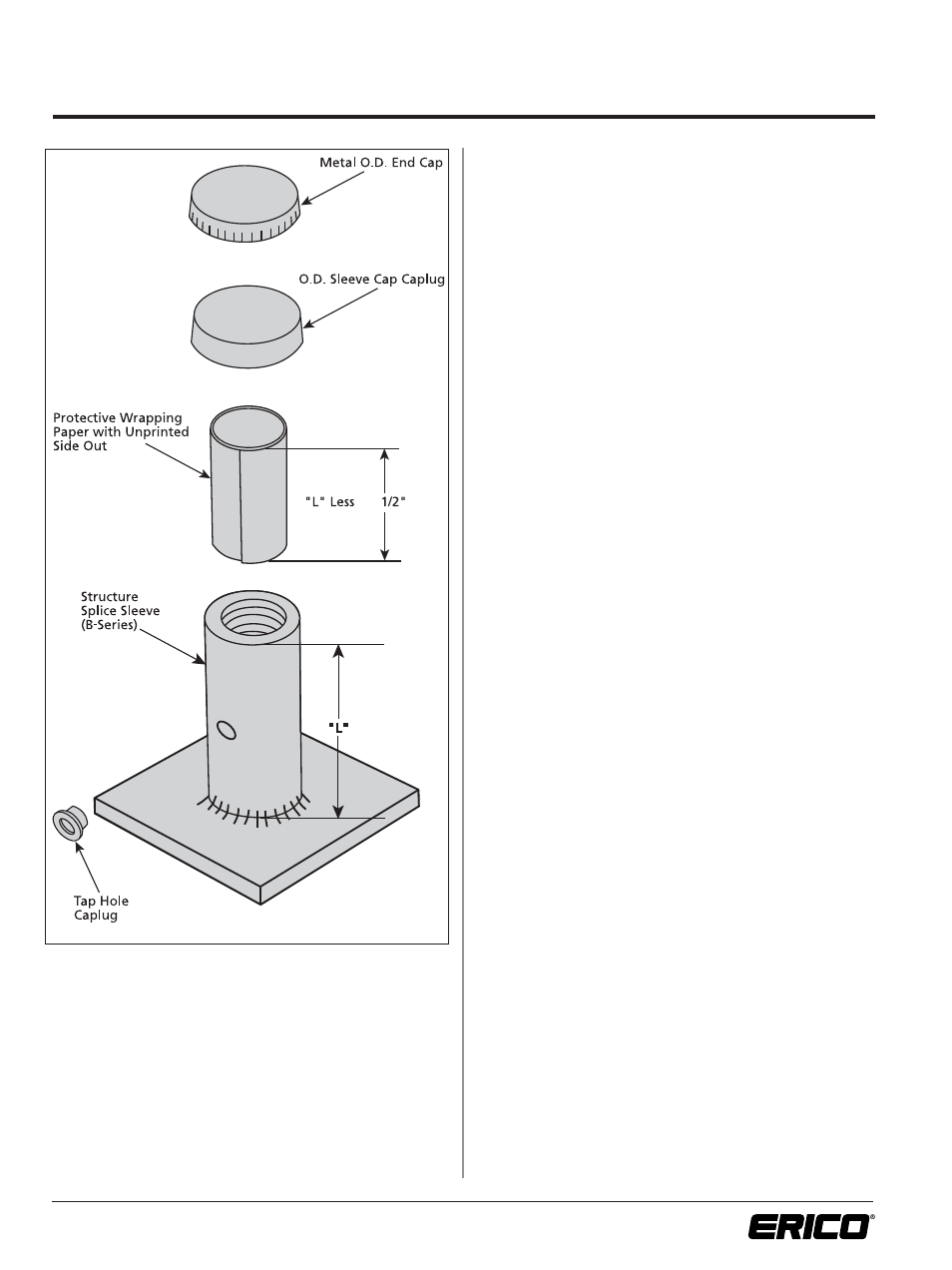

1. Leave protective wrappers on sleeves until ready to arc

weld.

2. When removing protective wrappers, avoid tearing as

wrappers must be inserted in sleeves after welding and

before caplugs are installed as shown.

3. Cut or fold protective wrapping paper same length as

the sleeve (splice sleeve original wrapping.)

4. Insert paper into sleeve with unprinted side out.

5. Place O.D. sleeve cap caplug over sleeve and tap hole

caplug in tap hole (and vent hole plug in vent hole if

required). See table in catalog for proper part number.

6. Caplugs must be kept tightly in place until removed for

splicing bar in sleeve.

7. As an additional precaution against moisture, it is

suggested that polyethylene sheet, tarpaulins, building

paper or other protective cover be used to cover sleeves

after welding and until they are spliced.

8. If CADWELD

®

splicing of the welded assembly will not

occur for a week or more, it is recommended that the

metal O.D. end cap be placed over the end of the sleeve

and secured with all weather pipe tape to hold it in

position. The metal end cap will protect against dislodging

or puncturing of the plastic O.D. caplug.

9. When ready to complete the connection of rebar to the

sleeve, remove end caps, plugs, paper and flame dry

sleeve thoroughly.

NOTES:

1. O.D. sleeve cap caplug, tap hole caplug, and paper must

be placed in sleeve as soon as sleeve has cooled after

welding to effectively prevent internal rusting.

2. Part numbers for these accessories are listed in the

catalog. See catalog for additional information.

Welding of Splice Sleeves to Structural Steel

Splice sleeves are generally arc welded to the structural steel in

a fabricating shop. The design of the weld, the selection of

the electrode, etc. depend on the chemical and physical

properties of the structural steel to which the splice sleeves

are welded. The engineer designing the assemblies should

refer to the pertinent codes and recommended practices of

the American Concrete Institute, American Welding Society,

etc.

Care of Finished Assemblies

Following the instructions on this page, CADWELD

®

B-Series

sleeves welded to the finished assemblies are covered to inhibit

rusting and foreign contaminants from entering the sleeve

interior.