Instructions for venting cadweld, Horizontal splices – ERICO CADWELD for Rebar Splicing System User Manual

Page 10

8

www.erico.com

Instructions For

Venting CADWELD

®

Horizontal Splices*

The use of wire or nails for venting is two-fold. Primarily,

they raise or lift the sleeve from the top of the rebar, creat-

ing a gap between the sleeve and bar. The gap is necessary

for proper fill at the top of a horizontal splice. Gravity takes

care of filling the bottom of the sleeve.

The second purpose of the wires or nails is to provide a

path for the escape of air from the inside of the sleeve.

During splicing, air inside the sleeve is greatly expanded by

the incoming molten metal. If this air is trapped in the

sleeve, it takes up volume and will not allow the metal to

fill correctly. Creating an avenue of escape (with the wires

or nails) allows the metal to adequately fill the splice sleeve.

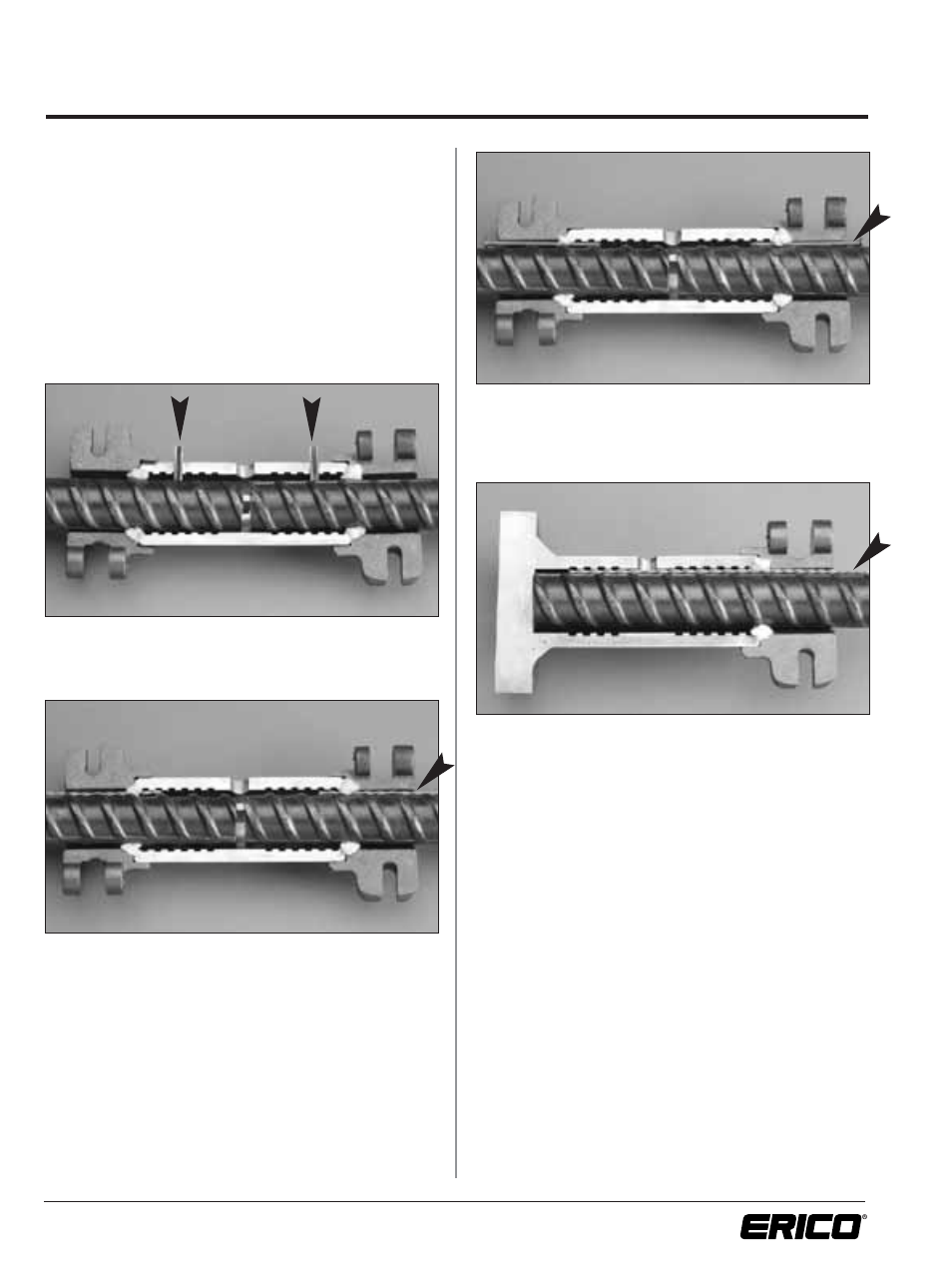

Venting with vent pins. Raise sleeve until it touches the

bottom of the bar and firmly drive down vent pins with a

hammer.

Venting with twisted tie wire. Place uncoated steel wire

on top of bar. Wire should be long enough to protrude

approximately 2-in. (50 mm) into sleeve and out beyond

End Alignment Fitting as shown above.

Venting with nails. Place uncoated steel nail on top of

bar. Nail should be long enough to protrude approximately

2-in. (50mm) into sleeve and out beyond End Alignment

Fitting as shown above.

Venting of B-Series structure splice with twisted tie

wire. Place uncoated steel wire on top of bar. Wire should

be long enough to protrude full length of sleeve and out

beyond End Alignment Fitting as shown above.

*Formerly Bulletin 101