Addenda, Continued) – ERICO CADWELD for Rebar Splicing System User Manual

Page 16

Addenda

(continued)

Tap Hole Relocation

Due to unforeseen clearance restrictions, B-Series sleeves are

sometimes welded to structure assemblies with their tap hole

oriented in the wrong directions, preventing the splicing

equipment from fastening to the sleeve. In some instances

the only method of correction is to redrill a new tap hole in

a different location. This can be accomplished without altering

the function of the splice sleeve as long as the following con-

ditions are met.

1. The new tap hole should be the same size and distance

from the end of the sleeve as the original tap hole.

2. When splicing a standard grade 60 (420 MPa) reinforcing

bar, the abandoned tap hole should be plug welded using

at least an E70XX electrode or equivalent.

3. Drilling of the new tap hole should always be accomplished

without the assistance of cutting oils or other lubricants to

prevent contamination of the splice sleeve and subsequent

cleaning.

Erroded Tap Hole Repair

Improper seating of the pouring basin against the sleeve

can cause filler metal or slag leakage to occur, eroding small

amounts of the external splice sleeve surface. When it is

impractical to remove the sleeve, strength integrity can be

restored by building up the eroded area with at least an

E70XX electrode or equivalent.

Cleaning Rusty Sleeves

To clean B-Series sleeves that are welded to structural assem-

blies and have become rusty, we recommend the following

procedures:

1. Flame dry sleeves with torch to remove all moisture

and/or burn away any other foreign matter. Flame should

be soot free and not leave any residue or deposits on

the inside sleeve surface. A “rose-bud” torch tip is

recommended.

2. Using a solid end brush (contact ERICO

®

for brush size

and information), and a pencil grinder with compatible

revolutions per minute capacity, clean the inside sleeve

and plate surfaces.

3. Any pitting in the grooves not cleaned by the end brush

can be cleaned using a radial end brush (wheel brush).

The wheel brush can be attached to an arbor and used in

the pencil grinder.

4. Clean tap hole using a tube brush.

5. All brushes must be run dry. Lubricants or other abrasives

should not be used.

14

www.erico.com

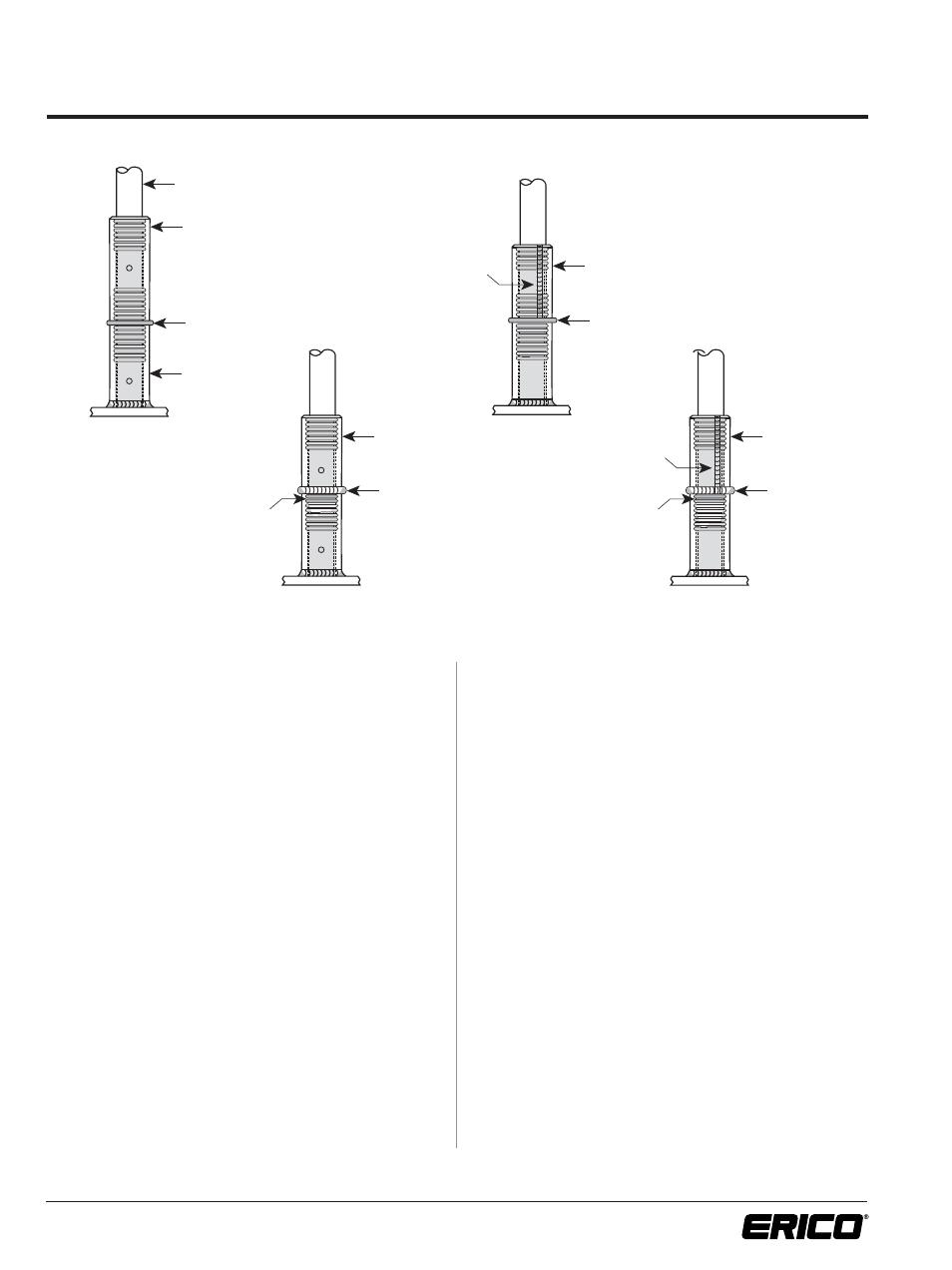

Rebar

CADWELD Bar-to-Bar

Splice Sleeve

Fillet Weld

Void filled with

filler metal

CADWELD

Structure

Splice Sleeve

(TYP)

Void packed with

packing material

CADWELD

Structure

Splice Sleeve

Structural

Weld

Packing

Material

Void packed with

packing material

CADWELD

Split Structure

Splice Sleeve

Structural

Weld

Packing

Material

Structural

Weld full

length of

sleeve

Void filled with

filler metal

CADWELD

Bar-to-Bar

Split Splice

Sleeve

Fillet Weld

Structural

Weld full

length of

sleeve