Figure 2 – Enerpac PL-Series User Manual

Page 4

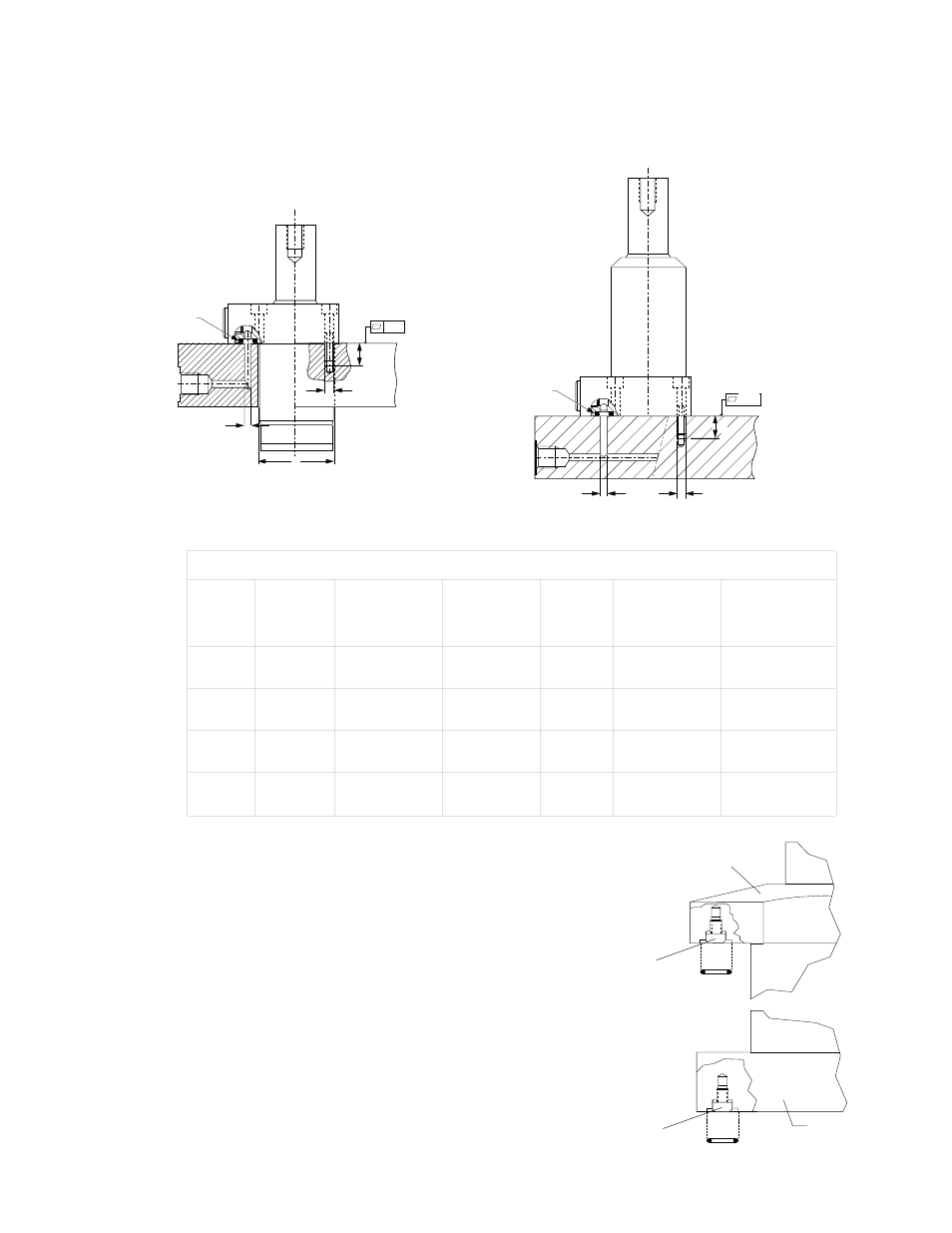

Mounting Upper and Lower Flange Cylinders

A

WARNING

The fixture must be capable of withstanding 350 bar (5000 psi) hydraulic

working pressure when cylinders are manifold mounted.

Manifold Specifications

Cylinder

Capacity

Max. Oil

Channel

Diameter

Ø A

Fixture

Hole Diameter

Ø B

Mounting

Threads

C

Minimum

Thread

Depth

D

Lubricated

Mounting Bolt

Torque

Manifold

O-Ring

Dimensions

I.D. x w.

2,2 kN

500 lb

4mm

0.156"

29,2

±

0,8

1.15

±

.03

M5

15 mm

0.59"

4,5-5,4 Nm

40-48 in-lbs.

6,07 x 1,78 mm

0.239 x 0.070"

5,6 kN

1250 lb

4mm

0.156"

36,0

±

0,8

1.42

±

.03

M6

15 mm

0.59"

12,2-14,9 Nm

9-11 ft-lbs.

7,65 x 1,78 mm

0.301 x 0.070"

9 kN

2000 lb

4mm

0.156"

49,1

±

0,8

1.93

±

.03

M6

15 mm

0.59"

13,5-15 Nm

10-11 ft-lbs.

4,34 x 3,53 mm

0.171 x 0.139

35 kN

7900 lb

4mm

0.156"

77,5 0,3

3.05

±

.01

M10

15 mm

0.59"

65-72 Nm

48-53 ft-lbs.

4,34 x 3,53 mm

.171 x .139"

Before manifold mounting the pull cylinder, remove

the port screw plugs and copper gaskets or o-rings.

Prior to mounting and bolting down the pull cylinder,

lubricate the o-rings provided and install them in the

counter-bore around the port.

Be sure that the o-ring does not get pinched or

damaged during mounting as leakage could result. To

prevent leakage from the manifold mounting, provide

a fixture mounting surface with flatness within 0.08

mm (0.003 in.) and a surface roughness not to exceed

Ra 1,6.

Remove port

screw plug.

o-ring

Lower

Flange

Remove port

screw plug.

o-ring

Upper Flange

0.003

A

C

D

0.003

A

B

C

D

Manifold

O-ring

Manifold

O-ring

0,1

0,1

Figure 2

4