Enerpac P-Series ULTIMA User Manual

Page 6

6

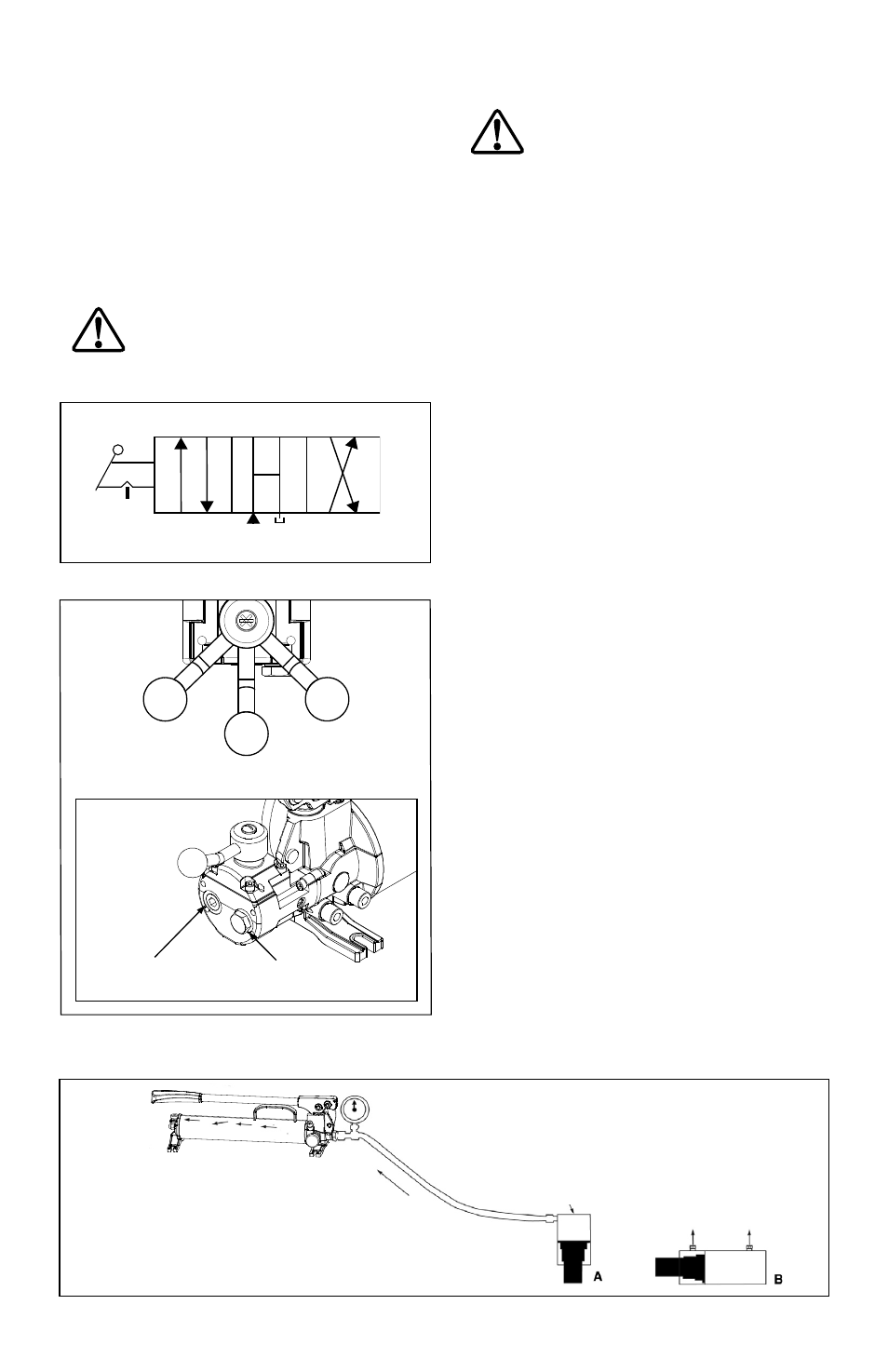

5.4 Pump Operation - Model P-84

The model P-84 is equipped with a 4-way, 3-position

control valve. It is designed for use with double-

acting cylinders. See figures 9 and 10.

1. Position lever on 4-way valve to select function as

follows:

(A) Flow directed to port “A”; port “B” returns flow

to the reservoir.

(N) Neutral - ports “A” and “B” open to the reservoir.

(B) Flow directed to port “B”; port “A” returns flow

to the reservoir.

WARNING: Valve contains no load holding

device. Be sure load is supported by

blocking, mechanical stands or other

appropriate supports before moving valve lever to the

neutral (N) position.

A

B

A

B

A

B

(A)

(N)

(B)

Figure 9, 4-Way Valve Diagram (P-84)

(B)

(A)

(N)

Port

“A”

Port

“B”

Figure 10, Control Valve Lever Positions

and Hose Connections (P-84)

2. Operate pump to perform work.

3. Change valve positions as needed.

WARNING: Operate double-acting

cylinder only when both hoses are

connected to the pump. If one coupler is

left unconnected, high pressure will build behind the

coupler which could cause personal injury and/or

equipment damage.

6.0 AIR REMOVAL

Removing air from the hydraulic system will help the

cylinder to advance and retract smoothly.

6.1 Pump With Single-Acting Cylinder

1. Loosen and remove oil fill plug to provide reservoir

venting during the following steps.

2. Fully close release valve.

3. Position pump in the horizontal position at higher

elevation than cylinder. See Figure 11.

4. Position cylinder with the plunger end down (up if

using pull cylinder).

5. Operate pump to fully extend the cylinder (retract

if using pull cylinder).

6. Open release valve to retract cylinder (extend if

using pull cylinder). This will force the trapped air

to move up to the pump reservoir.

7. Repeat steps 2 through 6 as needed, until cylinder

operation is smooth.

8. Add oil if necessary. See Section 9.1.

9. Reinstall oil fill plug.

6.2 Pump With Double-Acting Cylinder

1. Loosen oil fill plug several turns to allow reservoir

venting during the following steps.

2. Position pump in the horizontal position at higher

elevation than cylinder. See Figure 11.

3. Put cylinder in horizontal position with ports up.

4. Fully advance and retract the cylinder 2 to 3 times.

5. Repeat steps 2 through 4 as needed, until cylinder

operation is smooth.

6. Add oil if necessary. See Section 9.1.

7. Reinstall oil fill plug.

7.0 RELIEF VALVE ADJUSTMENT

1. All models except P-84: Install a 0-15,000 psi

[0-1000 bar] pressure gauge in the pump oil

outlet port. Close the release valve (turn knob fully

clockwise until it stops).

Figure 11, Air Removal

air

air

Single-acting

Cylinder

Double-acting

Cylinder