Application guidelines – Det-Tronics R7495D UV/IR Flame Detection System User Manual

Page 9

vidual application, taking into account all possible vari-

ables (see the Application Guidelines” section for a dis-

cussion of of these factors).

Typical response distances of the C7052J Detector to

various fuels are listed in Table 1. Each liquid fuel fire

(acetone, diesel, gasoline, methanol, and toluene) con-

sisted of approximately one pint of fuel burned in a 1

foot by 1 foot steel pan unless otherwise noted. The

excelsior (wood shaving) fire consisted of one pound of

wood shavings. The wood fire consisted of a 10-inch by

10-inch crib (wood stack). The methane fire was per-

formed to FM standard, with the flame approximately 30

inches high and 6 to 8 inches in diameter. The detec-

tors were sited to observe the fire at center axis ±10

degrees. The controller sensitivity and time delay set-

tings were 4 counts per gate, 4 consecutive gates, and

0.25 second gate lengths.

APPLICATION GUIDELINES

Certain guidelines must be followed when using any

type of sensing device as a fire detector. This involves

not only recognizing the strengths and advantages of a

particular device, but also understanding its limitations.

It is also important to note that in any system that uses

two or more sensors to produce a fire signal, the detec-

tor will be disabled should one of its sensors fail. The

Automatic oi feature will warn of such failure. Routine

manual testing and checking of the system is recom-

mended for increased system reliability.

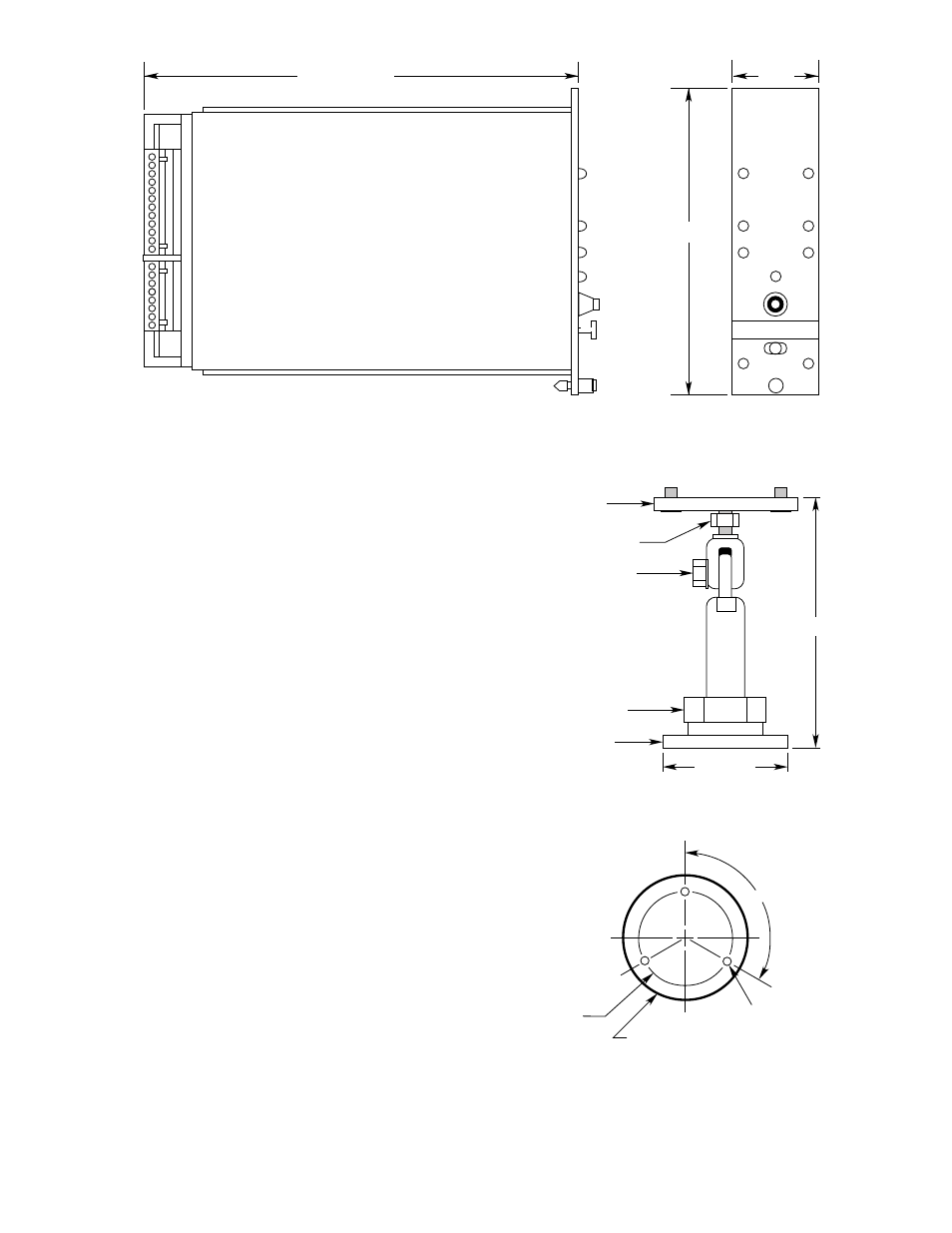

A1020

10.0 INCHES (254 MM)

2 INCHES

(50 MM)

7 INCHES

(177 MM)

9

95-8331

Figure 6—Controller Dimensions in Inches (Millimeters)

5-1/4 INCHES

(133 MM)

2-1/2 INCHES

(64 MM)

MOUNTING BASE

1/2 INCH NUT USED TO ADJUST

ELBOW TO DESIRED ANGLE

1-3/8 INCH NUT USED TO ROTATE

SWIVEL/DETECTOR ASSEMBLY

TO DESIRED POSITION

3/4 INCH NUT USED TO

SECURE DETECTOR

BRACKET TO SWIVEL MOUNT

JUNCTION BOX MOUNTING

BRACKET (ATTACHES

WITH TWO ENCLOSED

FLATHEAD SCREWS)

2–1/2 (64 MM) DIA.

0.25 (6.4 MM)

DIA. (3)

120

°

±

2

°

(2)

2.00 (50.8 MM) DIA.

B1303

B1303

Figure 7—Q9001G Swivel Mounting Bracket Dimensions

5-1/4 INCHES

(133 MM)

2-1/2 INCHES

(64 MM)

MOUNTING BASE

1/2 INCH NUT USED TO ADJUST

ELBOW TO DESIRED ANGLE

1-3/8 INCH NUT USED TO ROTATE

SWIVEL/DETECTOR ASSEMBLY

TO DESIRED POSITION

3/4 INCH NUT USED TO

SECURE DETECTOR

BRACKET TO SWIVEL MOUNT

JUNCTION BOX MOUNTING

BRACKET (ATTACHES

WITH TWO ENCLOSED

FLATHEAD SCREWS)

2–1/2 (64 MM) DIA.

0.25 (6.4 MM)

DIA. (3)

120

°

±

2

°

(2)

2.00 (50.8 MM) DIA.

B1303

B1303

Figure 8—Mounting Base Dimensions