Initial and periodic checkout procedure, Maintenance – Det-Tronics R7495D UV/IR Flame Detection System User Manual

Page 23

INITIAL AND PERIODIC CHECKOUT

PROCEDURE

The entire system should be periodically checked with a

UV/IR test lamp to be sure that the detectors are not

obstructed, that the area “seen” by the detector has not

changed, and that there is no fault in the oi circuit.

1. Place the Mode switch in the TEST position. The

FAULT LED will turn on.

CAUTION

Placing the controller in the Test mode inhibits the

outputs, rendering the system incapable of actuat-

ing any extinguishing or alarm circuits that are con-

nected to it. However, for maximum safety, secure

the output loads that would normally be actuated

by the system before performing the checkout pro-

cedure.

2. Shine the UV/IR test lamp into the viewing window

of the detector under test. The corresponding

DETECTOR LED flashes rapidly to identify the

detector under test.

If the requirements are met, the appropriate ALARM

LED and FIRE ZONE LED are also illuminated.

3. Turn off the UV/IR source. If turned on, the ALARM

LED and FIRE ZONE LED(s) continue to flash if

latching outputs are selected and are on steady if

not selected. The DETECTOR LED is on steady.

4. Repeat steps 2 and 3 for the other detector in the

system.

5. After all detectors have been checked, reset the

system by placing the Mode switch in the NORMAL

position. All LEDs except the POWER LED are off.

6. Restore power to the output loads and remove any

mechanical blocking devices.

STAR PROGRAMMING CHECKOUT PROCEDURE

1. Secure output loads (remove power from valves,

relays or other devices that might otherwise be

actuated by the UV/IR system) before testing.

2. Apply power to the UV/IR detection system.

3. Ensure that the area being monitored is operating

under normal conditions (equipment that would nor-

mally be on is on).

4. Place the UV/IR controller keyswitch in the NOR-

MAL position and monitor for one hour.

— If the rockers have been set correctly, transient

radiation in the area should not activate the system.

The upper and lower LED displays should remain

dark. If this is the case, lower (more sensitive) set-

tings can be attempted.

— If the system sensitivity is set too high, one of the

two DETECTOR LEDs will turn on, and depending

on the Fire Zone switch settings, one of the FIRE

ZONE LEDs may turn on. If this happens, set the

rocker switches for more counts per gate, for more

consecutive gates required for actuation, or for a

shorter gate length and repeat the test. Altering

detector placement may also decrease the suscep-

tibility of the system to transient radiation.

For further assistance, contact the Field Support Group

at Detector Electronics.

MAINTENANCE

The C7052J Detector requires no periodic calibration.

However, to maintain maximum sensitivity, the detector

viewing windows must be kept clean at all times. Even

a small amount of certain UV or IR absorbing materials

(sometimes barely detectable to the human eye) can

significantly reduce the sensitivity of the detector. The

windows and oi rings should be thoroughly cleaned on

a regular basis. The length of time between periodic

cleanings will be determined by the nature and amount

of contaminants present in the environment.

23

95-8331

17

18

19

20

21

22

23

24

25

26

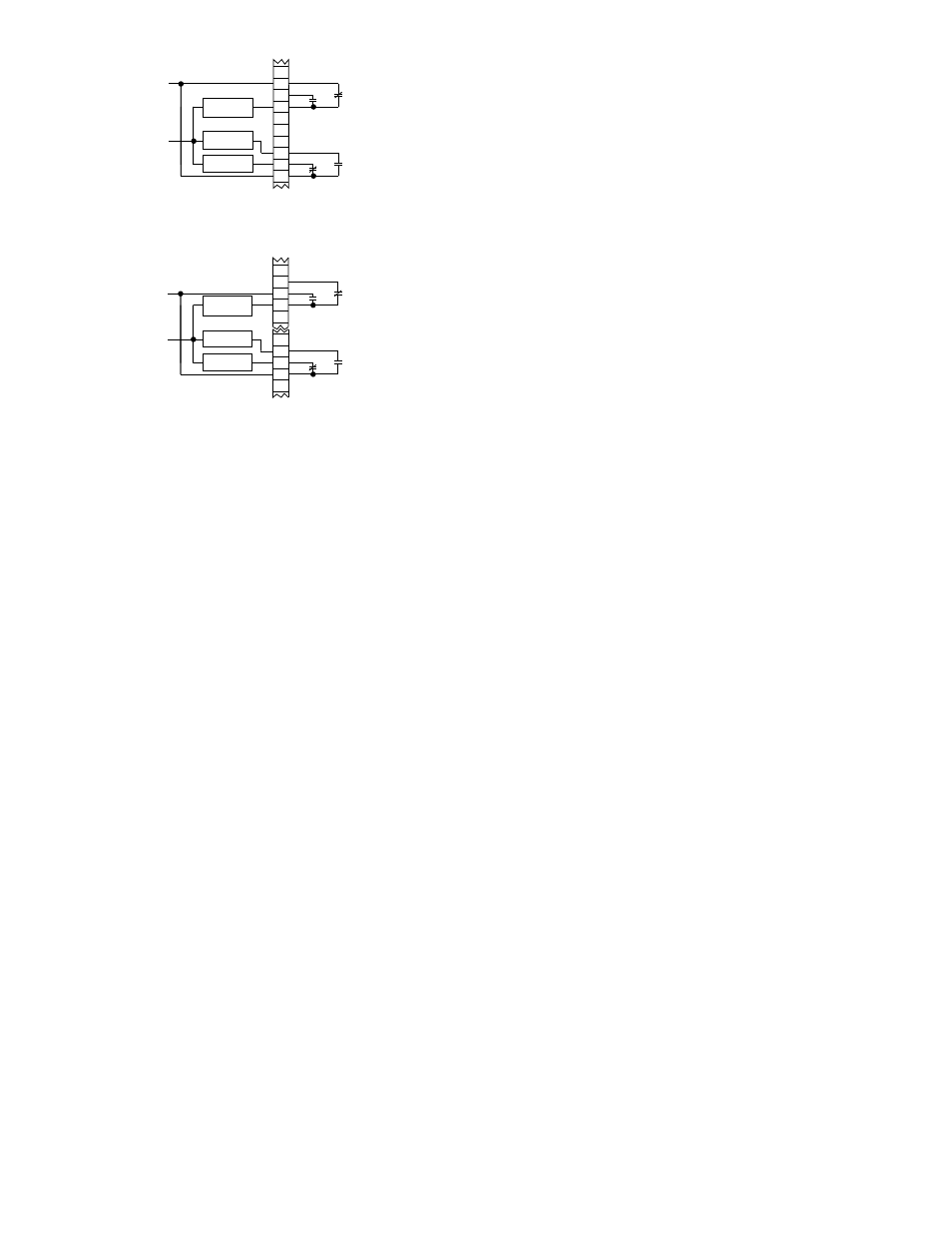

ALARM

RELAY

NO. 1

FAULT RELAY

FAULT RELAY SHOWN

IN NORMAL (ENERGIZED) CONDITION

A1057

FAULT

ALARM

LOAD

PROCESS

CONTROL

(

+

)H

(

–

)N

Figure 24—Normally Energized Load Circuit Connected to Alarm Relay

8

9

10

11

12

23

24

25

26

27

FIRE

RELAY

NO. 1

FAULT RELAY

FAULT RELAY SHOWN

IN NORMAL (ENERGIZED) CONDITION

A1058

FAULT

ALARM

LOAD

PROCESS

CONTROL

(

+

)H

(

–

)N

Figure 25—Normally Unenergized Load Circuit Connected to Fire Relay