Device repair and return, Engineering specifications – Det-Tronics R7495D UV/IR Flame Detection System User Manual

Page 25

DEVICE REPAIR AND RETURN

Prior to returning devices or components, contact the

nearest local Detector Electronics office so that an RMI

(Return Material Identification) number can be

assigned. A written statement describing the malfunc-

tion must accompany the returned device or component

to expedite finding the cause of the failure, thereby

reducing the time and cost of the repair.

Return all equipment transportation prepaid to the facto-

ry in Minneapolis.

ENGINEERING SPECIFICATIONS

The UV/IR flame detection system shall have a micro-

processor-based controller that can operate 1 or 2

detectors and provide relay outputs. The controller

shall be field programmable for selecting time delay

length, sensitivity, voting output configuration, and

latching or non-latching operation. The system shall

operate on 24 vdc. The UV/IR flame detection system

shall be capable of responding to a 1 foot by 1 foot

gasoline fire at a distance of 50 feet. The detector shall

be capable of 1.0 second response time to an intense

fire signal. It shall not respond to radiation generated

by arc welding, x rays, or hot surfaces, but shall be

capable of responding to a fire in their presence. The

UV/IR flame detector shall be in a red, copper-free alu-

minum enclosure.

1

The detector shall be the Det-

Tronics model C7052J, no equal. The controller shall

be the Det-Tronics model R7495D Controller that fits in

the Det-Tronics model Q4004 Mounting Rack, which is

designed to fit standard 19 inch racks, no equal.

The UV/IR flame detector shall have one 3/4 inch NPT

2

entry for field wiring.

The controller shall have visual annunciation of fire and

fault conditions. The controller shall have two red LEDs

for individual detector alarm indications, one green LED

for power indication, one amber LED for fault indication,

two red LEDs for fire zone output indication, and one

red LED for alarm indication. The controller shall have

relay outputs through a plug-in backplate connector.

The signal processing shall require the UV radiation and

the flickering IR radiation to exceed field adjust thresh-

old levels and time delay before signalling an alarm

condition. The detector shall have an 80 degree cone

of vision and be of a modular plug-in design that allows

the UV and IR sensor modules to be easily field

replaced without the use of special tools. All optical

surfaces shall be easy to access for cleaning. No metal

rods shall be allowed in front of the sensor windows.

The UV/IR flame detector shall have optical testing

capabilities on both the UV and IR sensor. Films that

blind the UV sensor or the IR sensor shall cause a fail-

ure of the optical test.

The UV/IR flame detector shall be rated for an operating

temperature range of –40°F to +167°F (–40°C to +75°C)

and a storage temperature of –40°F to +185°F (–40°C to

+85°C). The detector shall operate over a humidity

range of 0 to 95% RH and be able to withstand 100%

condensing humidity for short periods of time. All print-

ed circuit boards shall be coated to provide protection

from environmental conditions. The UV/IR flame detec-

tor shall meet MIL-STD 810C for vibration and have a

swivel mounting bracket to provide a means to easily

mount and aim the detector.

The UV/IR flame detector shall be explosion-proof for

Class I, Division 1, Groups B, C and D; Class II,

Division 1, Groups E, F and G. The device shall be

rated NEMA 4 (dust-tight, watertight). The detector

shall be FM approved.

3

An explosion-proof UV/IR test lamp shall be provided to

allow field testing of the UV/IR flame detection system.

The test lamp shall be FM approved for use in Class I,

Division 1, Groups C and D hazardous areas. The

explosion-proof UV/IR test lamp shall be the Det-Tronics

model W867, no equal.

2

5

95-8331

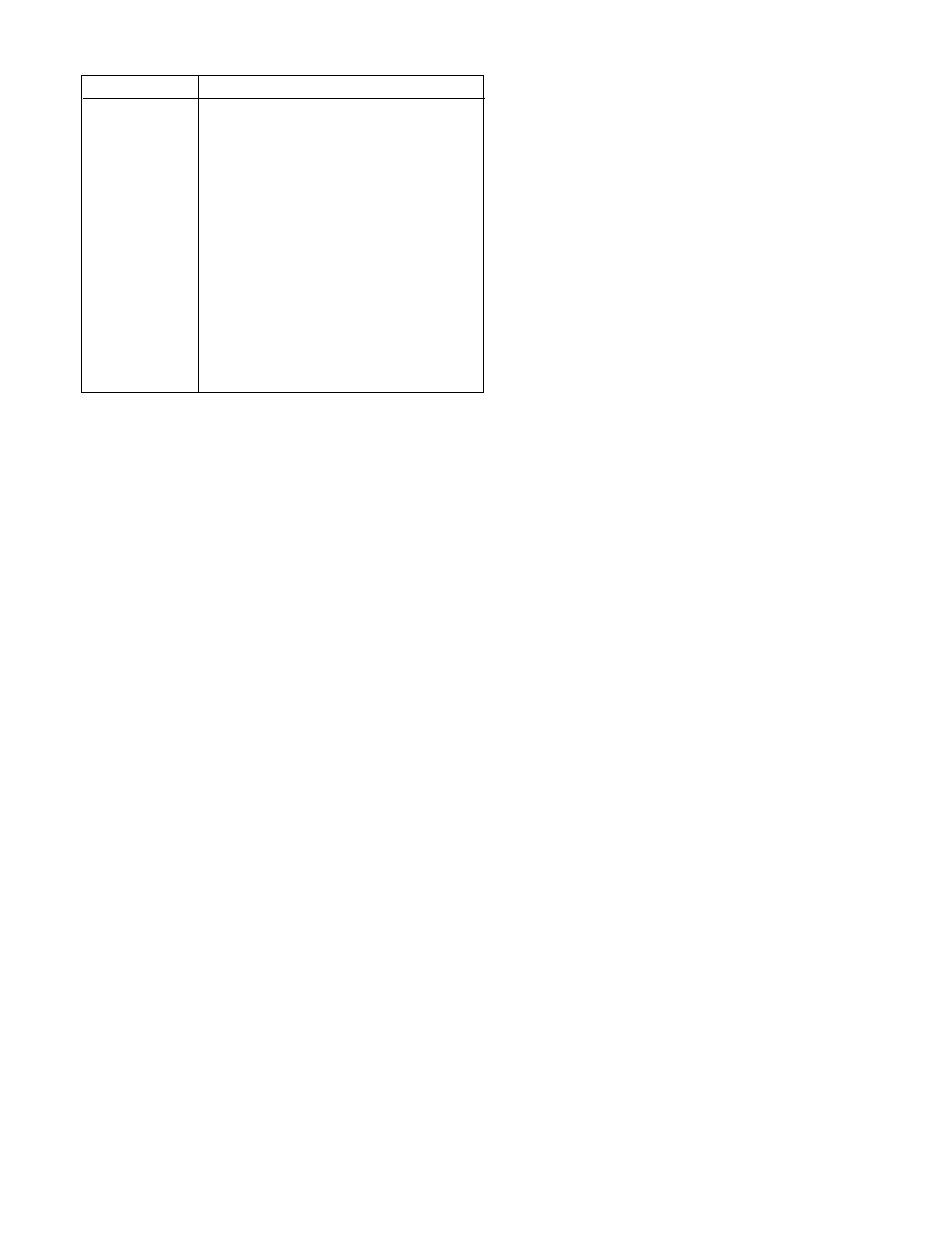

Table 3—Troubleshooting Guide

Indication

Status

FAULT LED on

Mode switch in Test position, external reset

activated, or fault in controller circuitry.

FAULT LED

oi fault - the oi ring and/or the window of the

and a

detector indicated by the DETECTOR LED

DETECTOR

is dirty, the detector tube module has lost

LED on

sensitivity or is missing, or there is an open or

shorted wire between that detector and the

controller.

FAULT LED

One or more detectors are responding to a

off and any

radiation source that is not large enough to

DETECTOR LED reach the fire threshold programmed into

blinking slowly

the controller, or one or more detectors may

be overly sensitive.

POWER LED off

No power to controller.