Introduction – Despatch LCC/LCD2-14-3 Non Pass Through Series User Manual

Page 10

1

INTRODUCTION

The LCC/LCD2-14-3 SERIES offers HEPA filtration for processes where minimization of

contamination is essential. The removable HEPA (High Efficiency Particulate Air) filter is

designed to provide a constant flow of clean air to the product being heated. The HEPA

filter with silicone seal provides 99.99% filtration. A magnehelic differential pressure

gauge monitors pressure drop across the HEPA filter.

The LCC2-14-3 Series ovens are rated up to 260 C, and are available with air, inert

(nitrogen), or “Class A” atmospheres. The LCD2-14-3 Series have all the above listed

atmosphere options, but with a maximum temperature of 350 C. Additionally, silicone

free construction is available on all models.

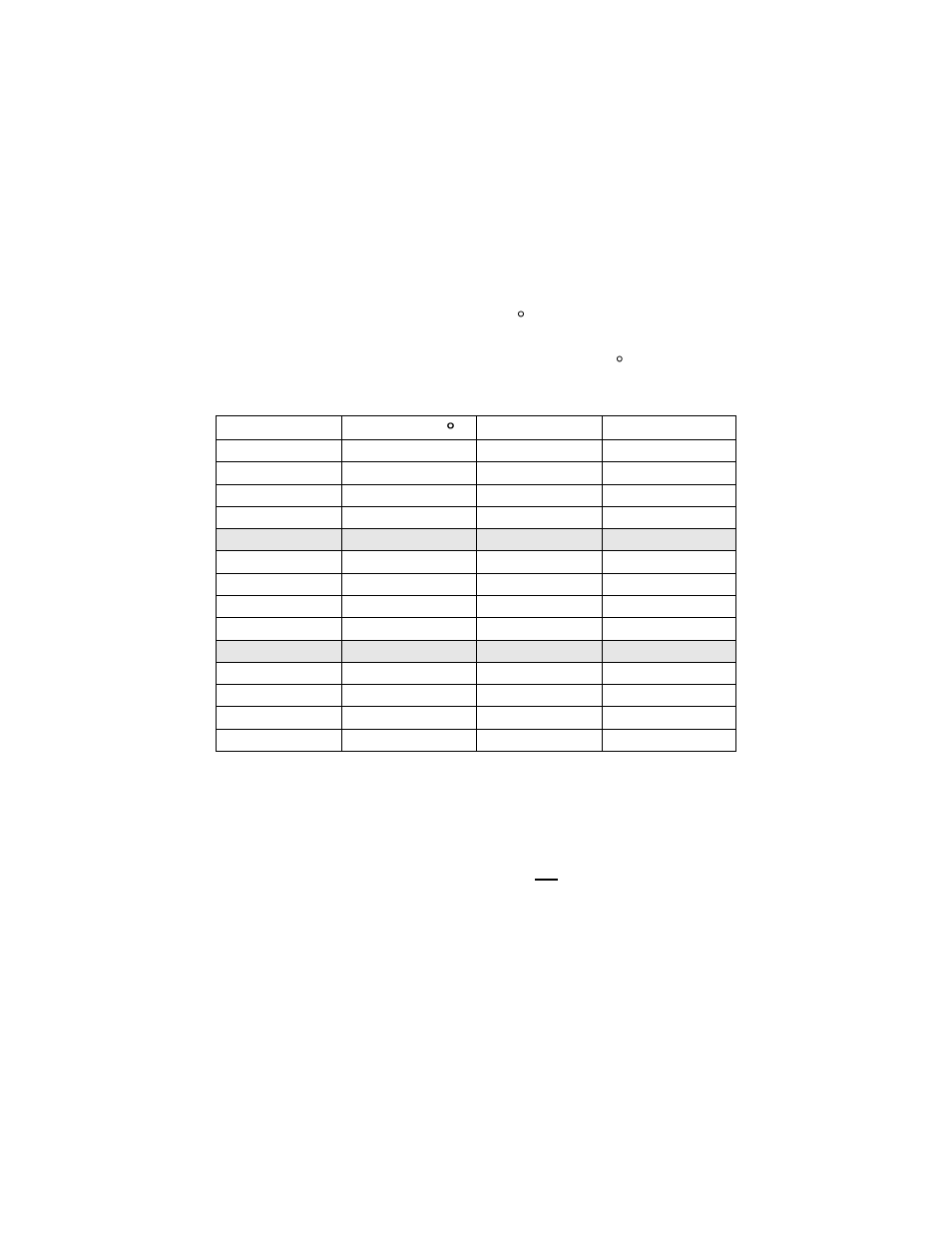

Atmosphere Max Temp C

Seals

Model

Air

260

Silicone

LCC2-14-3

Air

260

Silicone Free LCC2-14V-3

Air

350

Silicone

LCD2-14-3

Air

350

Silicone Free LCD2-14V-3

Inert

260

Silicone

LCC2-14N-3

Inert

260

Silicone Free LCC2-14NV-3

Inert

350

Silicone

LCD2-14N-3

Inert

350

Silicone Free LCD2-14NV-3

Class A

260

Silicone

LCC2-14A-3

Class A

260

Silicone Free LCC2-14AV-3

Class A

350

Silicone

LCD2-14A-3

Class A

350

Silicone Free LCD2-14AV-3

The voltages available are 208V / 3 phase, 240V / 3 phase, 415V / 3 phase, and 480V /

3 Phase; all ovens use a 16kW heater. A 380V / 3 phase option is available, the heater

is rated for 12kW.

Model numbers that begin with the designation LL*1-* are without HEPA filter.

The oven’s operator interface components are located on the hinged control panel at

the front of the oven. The power components; fuse blocks and motor starters are

located on the equipment panel, behind the hinged control panel for easy access. The

tr

ansformer and the heater SSR’s are located in the lower compartment with the

recirculation and exhaust/cooling motors. Electrical components are either touch-proof

or are shielded with Lexan to prevent accidental exposure during maintenance and

troubleshooting.

The optional Despatch Protocol Manager software is used to enable customer PC

control of an oven. Despatch Protocol Plus controllers may be networked together with

a Modbus communication option when multiple ovens are operated.