Troubleshooting, Disassembly information, Disassembly – JLG 1250AJP Service Manual User Manual

Page 74: Disassembly information -26 disassembly -26, Troubleshooting -26

SECTION 3 - 1CHASSIS & TURNTABLE

3-26

– JLG Lift –

3121171

TROUBLESHOOTING

The following table is provided to help locate problems in

the gearbox.

Disassembly Information

It is also important that this procedure is undertaken in a

workshop that is equipped with the proper tools. As well

as normal workshop tools it will be necessary to use spe-

cial tools that can be made (see special tools attachment)

or may be requested from the manufacturer.

Special Tools:

Puller...............................................Code/: 6689960240

Tool for lifetime seal assembly........Code/: 6689960300

Puller for brake disassembly..........Code/: 6689960310

Torque multiplier............................Code/: ATZ.09.016.0

To be able to produce these special tools refer to Figure 3-

20. thru Figure 3-23.

It is important to strictly adhere to all the procedures for

disassembling and reassembling the gearbox. Proceed

with these instructions using all the necessary safety mea-

sures, for example:

1. Plug all the Hydraulic ports on the gearbox to avoid

the introduction of any foreign particles in the circuit

and the gearbox.

2. Making sure that the coupling surfaces are not dam-

aged.

3. Handle with care so as to be sure that there are no

risks for personnel safety and to guarantee the reli-

ability of the gearbox.

4. Making available a work area that is in line with work

and health safety in the workplace guidelines.

Disassembly

NOTE: Below are all the steps to follow during Disassembly

and Assembly. Numbers in brackets in the text corre-

spond to the references in the exploded view.

Initial inspection can be made without disassembling the

hub from the machine. Before wheel drive disassembling,

make sure that the oil is drained from the hub.

Unscrew and remove the nos. 2 screws M12, grade 8,8,

and remove the hydraulic motor and its O-ring seal (48).

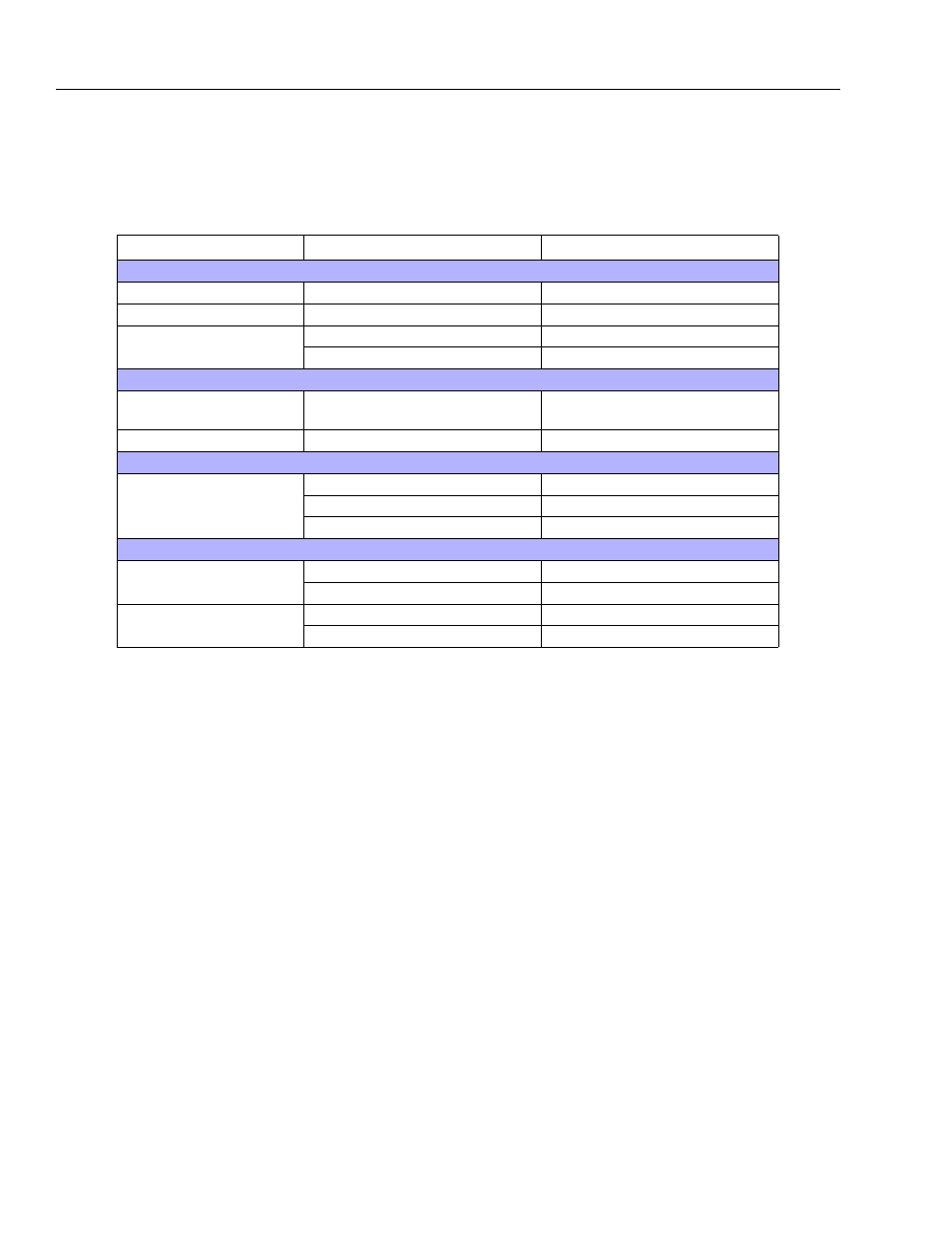

Table 3-5. Troubleshooting

Symptom

Causes

Remedies

External oil leakage:

From the lifetime seal

a) Lifetime seal damaged

a) Replace lifetime seal

From the end cover

a) O-ring seal damaged

a) Replace O-ring seals

From the plugs

a) Plug seal damaged

a) Replace plug seal

b) Plugs or screws loose

b) Tighten the plugs/screws

Too much noise:

Hydraulic noise (during the slowing

down of the motor speed)

a) Hydraulic circuit malfunctioning

a) Verify hydraulic circuit

Inside the gearmotor (reductions)

a) Internal damage

a) Check the gearbox

Other:

Overheating

a) Insufficient oil level

a) Check the oil level and refill if necessary

b) Hydraulic oil too warm

b) Check the hydraulic circuit

c) Brake not fully released

c) Check brake release pressure

Parking brake malfunctioning

Insufficient braking torque

a) Brake discs worn

a) Replace brake disc pack

b) Damaged parts

b) Check brake components

Wheel Locked

a) Parking brake locked

a) Check the complete brake release

b) Mechanical components damaged

b) Replace damaged parts