Bleeding after installation, Bleeding after installation -113, Jib alignment timing marks -113 – JLG 1250AJP Service Manual User Manual

Page 353

SECTION 4 - BOOM & PLATFORM

3121171

– JLG Lift –

4-113

Bleeding After Installation

NOTE: Bleeding will be necessary if excessive backlash is

displayed after the actuator is installed. To do this,

bleeder valves must be installed in the actuator at the

locations shown below. The following steps are rec-

ommended when a minimum of two gallons (8 liters)

is purged.

1. Connect a 5 foot (1.5 m) long 3/16" inside diameter,

5/16" outside diameter clear vinyl drain tube to each

of the two bleeder valves. Secure the tubes in place

with hose clamps.

2. Place the end of the tubes in a clean 5 gallon (19 L)

container to collect the purged oil. The oil can be

returned to the reservoir when the procedure is com-

plete.

3. Open both bleeder valves 1/4 turn. Using the

hydraulic system, rotate the platform to the end of

rotation and maintain hydraulic pressure. Oil with

small air bubbles should be seen flowing through

the tubes. Allow 1/2 gallon (2 L) of oil to be purged

from the actuator.

4. Keep the bleeder valves open and rotate the plat-

form in the opposite direction to the end of rotation.

Maintain hydraulic pressure until an additional 1/2

gallon (2 L) of oil is pumped out.

5. Repeat steps 3 and 4. After the last 1/2 gallon (2 L)

of oil is purged, close both bleed nipples before

rotating away from the end of rotation.

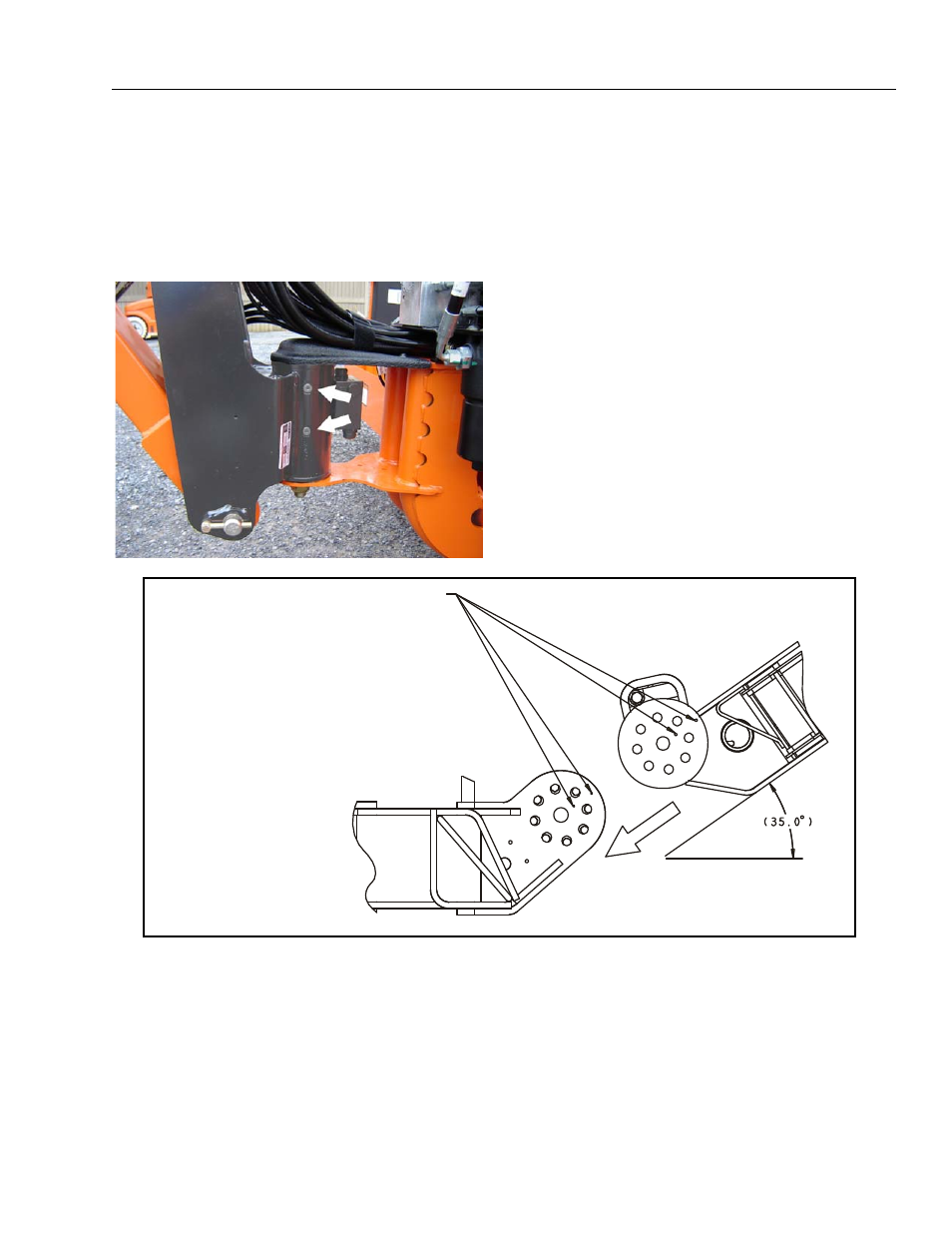

Figure 4-56. Jib Alignment Timing Marks

ALIGN TIMING MARKS IN ROTATOR WITH

TIMING MARKS IN PIVOT AS SHOWN

JIB WILL BE 35 DEGREES OUT OF LINE

WITH THE BOOM WITH ROTATOR CENTERED

REALIGN THE JIB WITH THE BOOM AFTER

ALL HARDWARE IS ASSEMBLED