11 lubrication & operator maintenance, Lubrication & operator maintenance -6, Lubrication & operator maintenance diagram -6 – JLG 1250AJP Service Manual User Manual

Page 24: Lubrication specifications -6

SECTION 1 - SPECIFICATIONS

1-6

– JLG Lift –

3121171

1.11 LUBRICATION & OPERATOR

MAINTENANCE

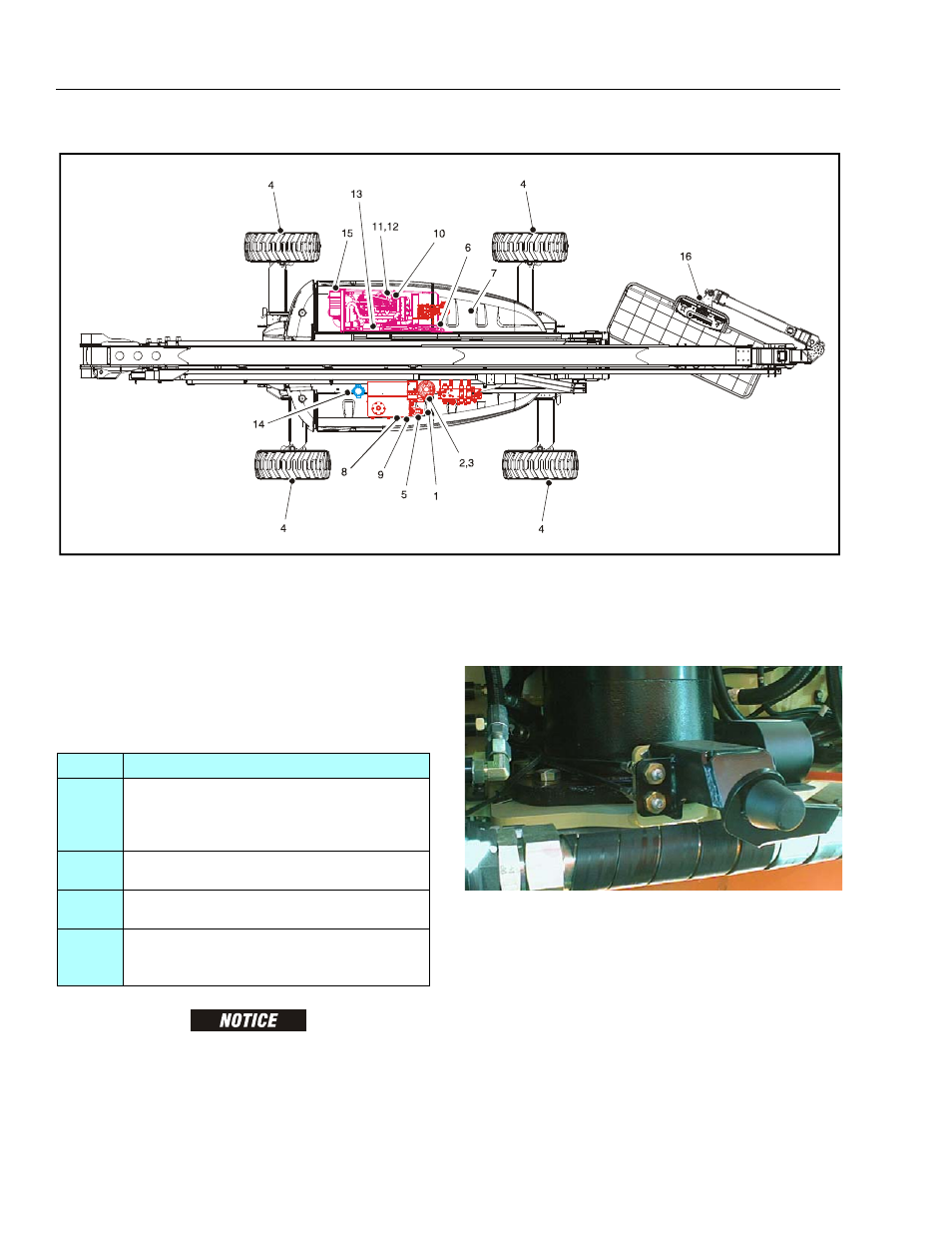

NOTE: The following numbers correspond to those in Fig-

ure 1-1., Lubrication & Operator Maintenance Dia-

gram.

LUBRICATION INTERVALS ARE BASED ON MACHINE OPERATION

UNDER NORMAL CONDITIONS. FOR MACHINES USED IN MULTI-

SHIFT OPERATIONS AND/OR EXPOSED TO HOSTILE ENVIRON-

MENTS OR CONDITIONS, LUBRICATION FREQUENCIES MUST BE

INCREASED ACCORDINGLY.

NOTE: It is recommended as a good practice to replace all

filters at the same time.

1. Swing Bearing - Remote Lube

Lube Point(s) - 2 Grease Fitting

Capacity - A/R

Lube - MPG

Interval - Every 3 months or 150 hours of operation

Figure 1-1. Lubrication & Operator Maintenance Diagram

Table 1-19. Lubrication Specifications

KEY

SPECIFICATIONS

MPG

Multipurpose Grease having a minimum dripping point of

350° F (177° C). Excellent water resistance and adhesive

qualities, and being of extreme pressure type.

(Timken OK 40 pounds minimum.)

EPGL

Extreme Pressure Gear Lube (oil) meeting API service

classification GL-5 or MIL-Spec MIL-L-2105

HO

Hydraulic Oil. API service classification GL-3, e.g. Mobil-

fluid 424.

EO

Engine (crankcase) Oil. Gas - API SF, SH, SG class, MIL-L-

2104. Diesel - API CC/CD class, MIL-L-2104B/MIL-L-

2104C.