5 cab installation, Cab installation – JLG G6-42A Service Manual User Manual

Page 87

4-11

G6-42A, G9-43A, G10-43A

Cab and Covers

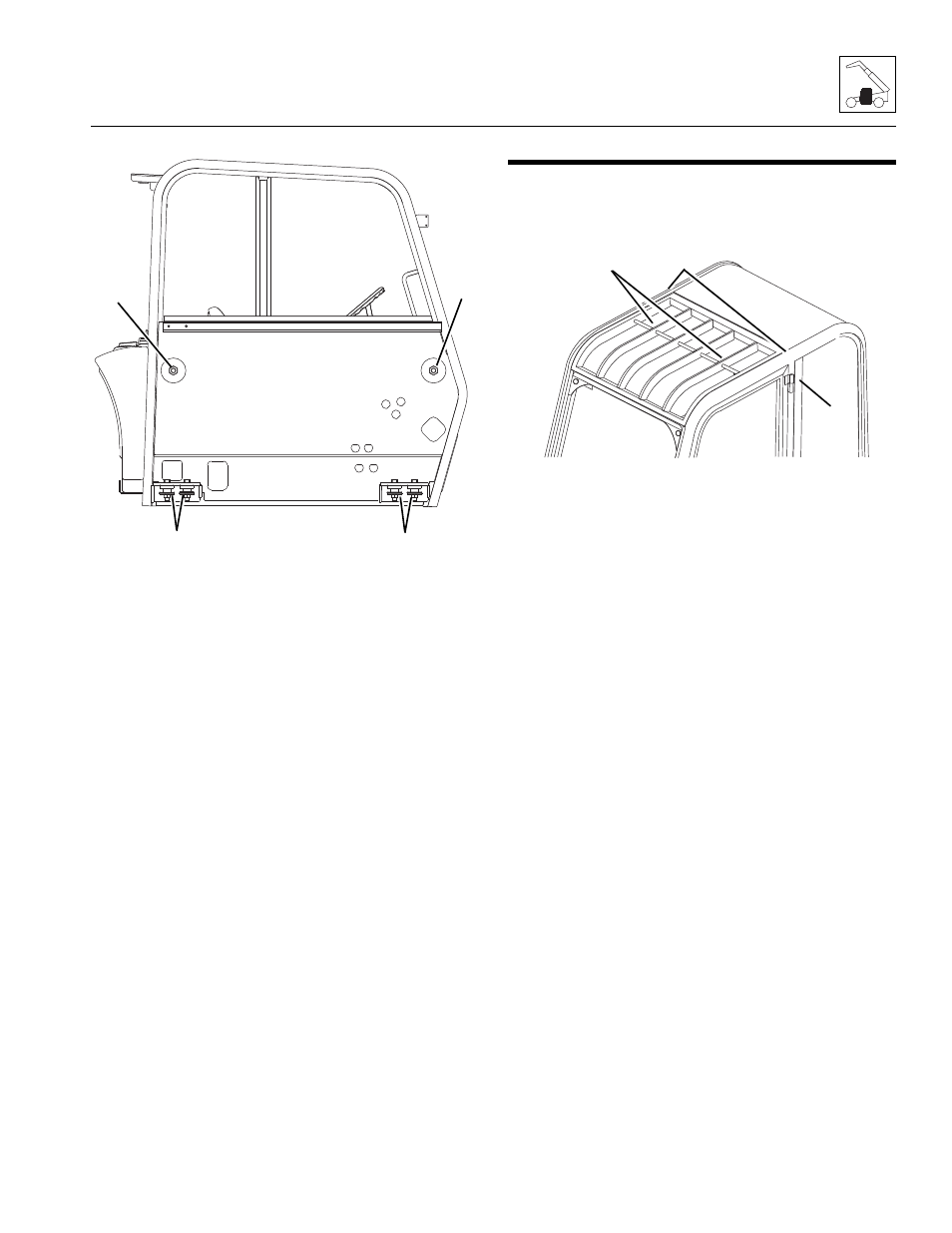

20. Remove two cab side-mount bolts in cab (17).

21. Remove the four cab-to-frame bolts, flat washers and

nuts (18).

22. Remove the mirrors and all other cab components

as needed, if not previously removed.

23. Carefully begin to lift the cab. Stop and check that all

wiring, hydraulic hoses and fasteners are

disconnected or removed.

24. When all wiring, hydraulic hoses and fasteners are

disconnected or removed, carefully and slowly lift the

cab and remove it from the frame. Readjust the

position of the sling as needed to help balance the

cab during removal.

25. When cab is completely clear of machine, carefully

lower it to ground. Block up or support the cab so

that it does not move or fall. Assure that no

personnel enter cab while it is being removed from

the machine.

26. Inspect condition of fittings, clamps, hydraulic hoses,

etc. Replace parts as indicated by their condition.

27. Inspect and replace machine parts that are exposed

with cab removed. Repair or replace as required.

4.5

CAB INSTALLATION

1. Block all four wheels to help prevent the machine

from moving. Assure that there is sufficient overhead

and side clearance for cab installation.

2. Open Cab: Route a sling with a minimum lifting

capacity of 1000 lbs (453 kg) under the inner four

braces (14) and behind the center cross support

above the wind shield or install two lifting eye bolts

(15) in the threaded holes on the roof of the cab

above the B pillars (16).

3. Enclosed Cab: Install two lifting eye bolts (14) in

threaded holes on roof of cab above B pillars (16).

4. Use a hoist or overhead crane and sling attached to

the cab. Carefully begin to align the cab with the

mounting holes in the frame. Stop and check that

wiring, hydraulic hoses, cables, etc., will not be

pinched or damaged as the cab is positioned.

5. Readjust position of sling as needed to help balance

cab during installation.

MY4170

18

17

17

18

MY0610

14

15

16