2 quick switch removal, 3 quick switch installation, 10 boom wear pads – JLG G6-42A Service Manual User Manual

Page 64: 1 wear pad inspection, 2 wear pad installation and lubrication, Boom wear pads, Quick switch removal, Quick switch installation, Wear pad inspection, Wear pad installation and lubrication

Boom

3-26

G6-42A, G9-43A, G10-43A

3.9.2

Quick Switch Removal

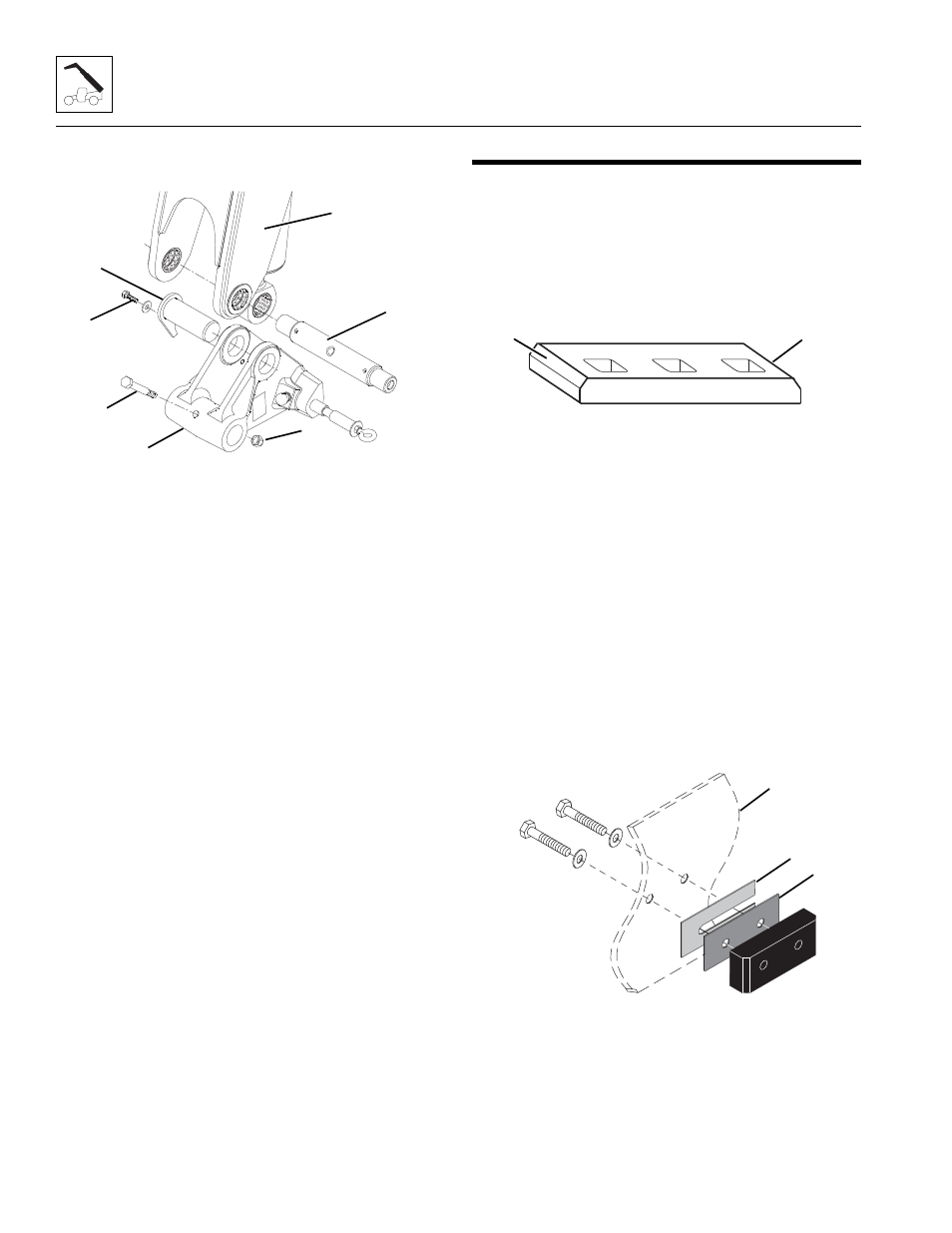

1. Remove the lock bolt (8) holding the tilt cylinder rod

end pin (9) to the quick switch assembly (10).

Remove the Tilt Cylinder pin.

2. Support the quick switch assembly (10).Remove the

capscrew (11) and locknut (12) securing the head

pin (13) to the boom head (14).

3. Inspect the above pins for nicks or surface corrosion.

Use fine emery cloth to fix minor nicks or corrosion.

If damaged or if it cannot be repaired the pin must be

replaced.

3.9.3

Quick Switch Installation

1. Assemble the quick switch assembly (10) to the

boom head (14). Line up the quick switch between

the mounts on the boom head. The quick switch

should be centered in the boom head.

2. Coat the quick switch head pin (13) with an anti-

seize compound. Insert the quick switch head pin

through the quick switch and boom head. Secure

with the previous capscrew (11) and locknut (12).

3. Align the quick switch with the tilt cylinder rod end

and insert the tilt cylinder pin (9). Align the tilt

cylinder pin and screw in the locking bolt (8). Torque

as required.

3.10

BOOM WEAR PADS

The wear pads on this machine are flat rectangular wear

pads with metal inserts.

A total of 30 wear pads are installed on the boom sections

of the G6-42A, G9-43A and G10-43A machines.

3.10.1

Wear Pad Inspection

Inspect all wear pads for wear. If angle indicators (1) on

ends of wear pads are visible, wear pads can be reused.

If the pads show uneven wear (front to back), they should

be replaced. Replace pads as a set if worn or damaged.

3.10.2

Wear Pad Installation and Lubrication

Note: Inspect all wear pads. Replace as necessary.

The following wear pad procedure must be followed to

insure the proper wear pad installation:

1. Wear pad inserts and mounting bolts MUST be

clean from any grease, oil or other contaminates

before applying Loctite

®

242™

and installing

mounting bolts.

2. Apply Loctite

®

242™

to all wear pad mounting bolts.

3. A spacer (2) with holes must be used before any

shim (3) is used.

4. A shim (3) must be inserted between spacer (2) and

wear pad support plate, block or boom section (4).

5. The number of shims can vary at each shim point.

MY5090

13

12

10

11

8

9

14

Ma2070

1

1

MAM1390

4

3

2