JLG G6-42A Service Manual User Manual

Page 104

Transmission

6-4

G6-42A, G9-43A, G10-43A

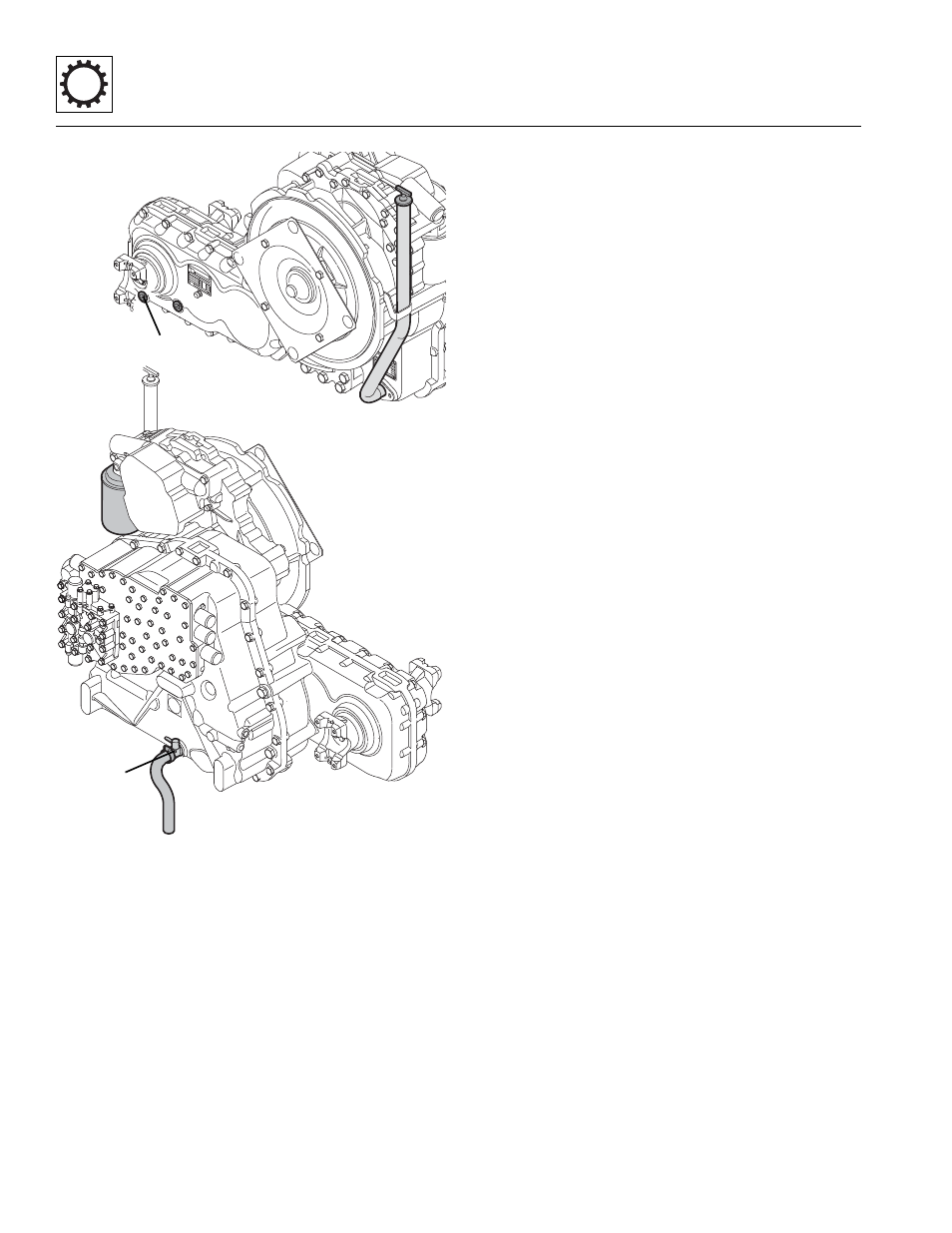

8. Place a suitable receptacle under transmission drain

hose (2). Open transmission drain valve, and allow

transmission oil to drain into receptacle. Repeat

drain procedure with the drop box (3).

9. Transfer used transmission oil into a suitable,

covered container, and label container as “Used Oil.”

Dispose of used oil at an approved recycling facility.

Clean and reinstall the transmission drain plug.

10. Remove the transmission-to-axle drive shafts. Refer

to Section 5.5.3, “Drive Shaft Removal.”

11. Remove exhaust components from turbo to exhaust

pipe. Refer to Section 7.5, “Engine Exhaust

System.”

12. Remove the implement pump. Refer to Section

8.6.1, “Implement Pump Replacement.”

13. Label and disconnect transmission temperature

switch connector and shift solenoid wiring

harness connectors.

14. Label, disconnect and cap the transmission oil

cooler inlet and outlet hoses at the transmission.

15. Remove access cover from bottom of engine bell

housing. This will allow access to remove four bolts

holding the torque convertor diaphragm to the

engine flywheel.

16. Turn the engine over slowly by hand and align each

of the four torque convertor diaphragm bolts to be

accessed. Remove them one at a time.

17. Wipe up any spilled hydraulic and transmission oil.

18. Connect a lifting strap or chain to lifting eye at top of

transmission, and to a suitable hoist or overhead

crane. Operate hoist or crane to remove slack from

chain, but DO NOT raise transmission at this time.

19. Place blocks under rear of engine for support

BEFORE transmission mounts are removed.

20. Place blocks under the transmission to help support

it during removal.

21. Remove both rear transmission mount bolts and

lockwashers securing transmission mount to frame.

22. Remove the bolts and washers holding the

transmission to the engine.

23. Remove capscrews and lockwashers securing rear

transmission mount to transmission.

24. Carefully remove the transmission from the machine.

Avoid causing damage to the transmission or

surrounding parts.

25. Lift the transmission clear of the machine, and lower

it onto suitable supports or secure it to a stand built

especially for transmission or engine service. Secure

the transmission so that it will not move or fall.

26. Remove any external transmission components as

required, including the transmission temperature

switch, and inlet and outlet cooler hose fittings.

Cover all transmission openings.

MY8000

2

3