4 after transmission service or replacement, After transmission service or replacement – JLG G6-42A Service Manual User Manual

Page 106

Transmission

6-6

G6-42A, G9-43A, G10-43A

15. Apply a thin film of clean hydraulic oil to the new

transmission filter gasket. Install the new filter and

torque to 20-25 lb-ft (27-34 Nm).

16. Fill the transmission. Refer to Section 2.5, “Fluids

and Lubricant Capacities,” for proper capacity.

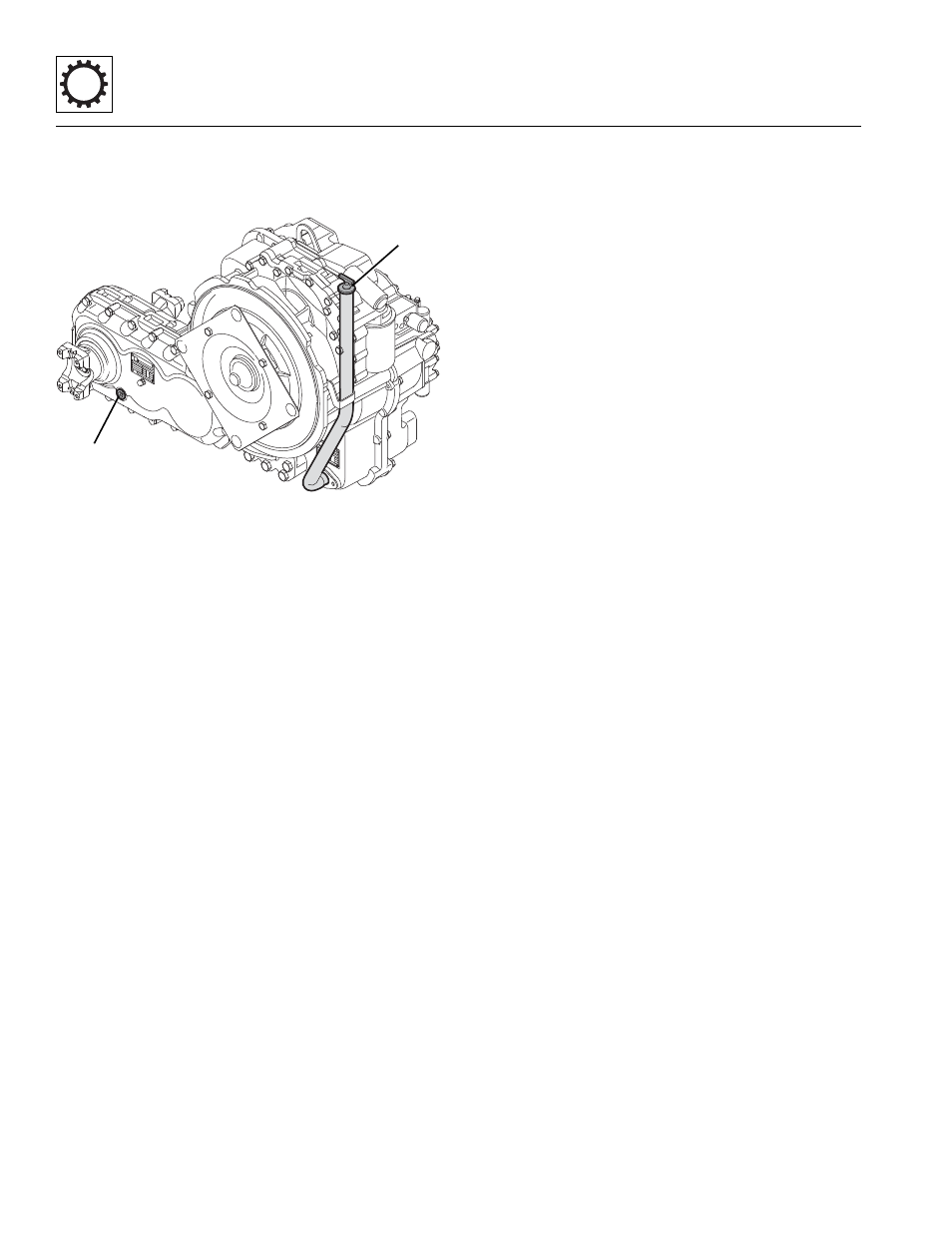

17. Transmission oil may be added through the dipstick

tube (5). Remove the dipstick and add hydraulic oil.

Check the fluid level by taking intermittent dipstick

readings as outlined in the appropriate Operation &

Safety Manual. DO NOT overfill. Reinstall the

dipstick when finished.

18. Transmission transfer case fluid may be added

through the fill plug (6). Install fill plug and tighten

when filled to appropriate level.

19. Properly connect the battery.

Note: Check transmission oil level with engine at idle

and transmission oil at normal operating temperature.

20. Apply park brake, shift transmission control lever to

the (N) NEUTRAL position and lower the forks or

attachment to the ground.

21. Remove the transmission dipstick (5) and check the

fluid level. The level should be at the MAX line.

22. If fluid is low, add fluid as required and recheck level.

23. Replace the transmission dipstick. when finished.

24. Install the engine cover.

25. Close and secure engine cover.

26. Recheck all drain plugs, lines, connections, etc., for

leaks, and tighten where necessary.Close and

secure the engine cover.

27. Remove the Do Not Operate Tags from both the

ignition key switch and the steering wheel.

6.4.4

After Transmission Service

or Replacement

In general:

1. Check transmission oil level and add oil as required.

2. Disconnect and clean all transmission cooler hoses.

When possible, remove transmission lines from the

machine for cleaning.

3. Drain and flush entire transmission cooling system.

4. Thoroughly clean transmission filter screens and

cases, and replace transmission filter elements.

Note: Check transmission oil level with engine at idle

and oil at normal operating temperature.

5. Reassemble all components and fill the transmission

with clean, fresh hydraulic oil through the dipstick

tube opening (5). Check the level by taking

intermittent dipstick readings as outlined in the

appropriate Operation & Safety Manual. DO NOT

overfill. Reinstall the dipstick when finished.

6. Transmission transfer case fluid may be added

through the fill plug (6). Install fill plug and tighten.

7. Apply park brake, shift transmission control lever to

the (N) NEUTRAL position and lower the forks or

attachment to the ground.

8. Remove the transmission dipstick (5) and check the

oil level. The oil level should be at the MAX line.

9. If oil is low, add oil as required and recheck level.

10. Replace the transmission dipstick. when finished.

11. Close and secure engine cover.

12. Recheck all drain plugs, lines, connections, etc., for

leaks, and tighten where necessary.

MY8030

5

6