9 quick switch assembly, 1 hydraulic quick switch removal, Quick switch assembly – JLG G6-42A Service Manual User Manual

Page 63: Hydraulic quick switch removal, Refer to section, 9, “quick switch assembly

3-25

G6-42A, G9-43A, G10-43A

Boom

13. Start the machine and at low idle, fully extend and

retract the boom three times. Verify boom is fully

retracted and level. Shut machine Off.

14. Verify dimension “A” 17.000-17.312 in

(421,8-439,7 mm). Verify dimension “C” is not

less than 3.069 in (77,9 mm).

Note: Re-adjust boom if dimensions “A” & “C” are not

met. Contact the local JLG Distributor if the procedure

cannot be obtained.

15. Loosen the retract chain lock nut and the extend

chain lock nut and apply Loctite

®

242

TM

.

16. Torque the retract chain lock nut (5) and extend

chain lock nut (1) without adding any additional

spring load. Torque each lock nut to 100 lb-ft

(135 Nm).

3.9

QUICK SWITCH ASSEMBLY

3.9.1

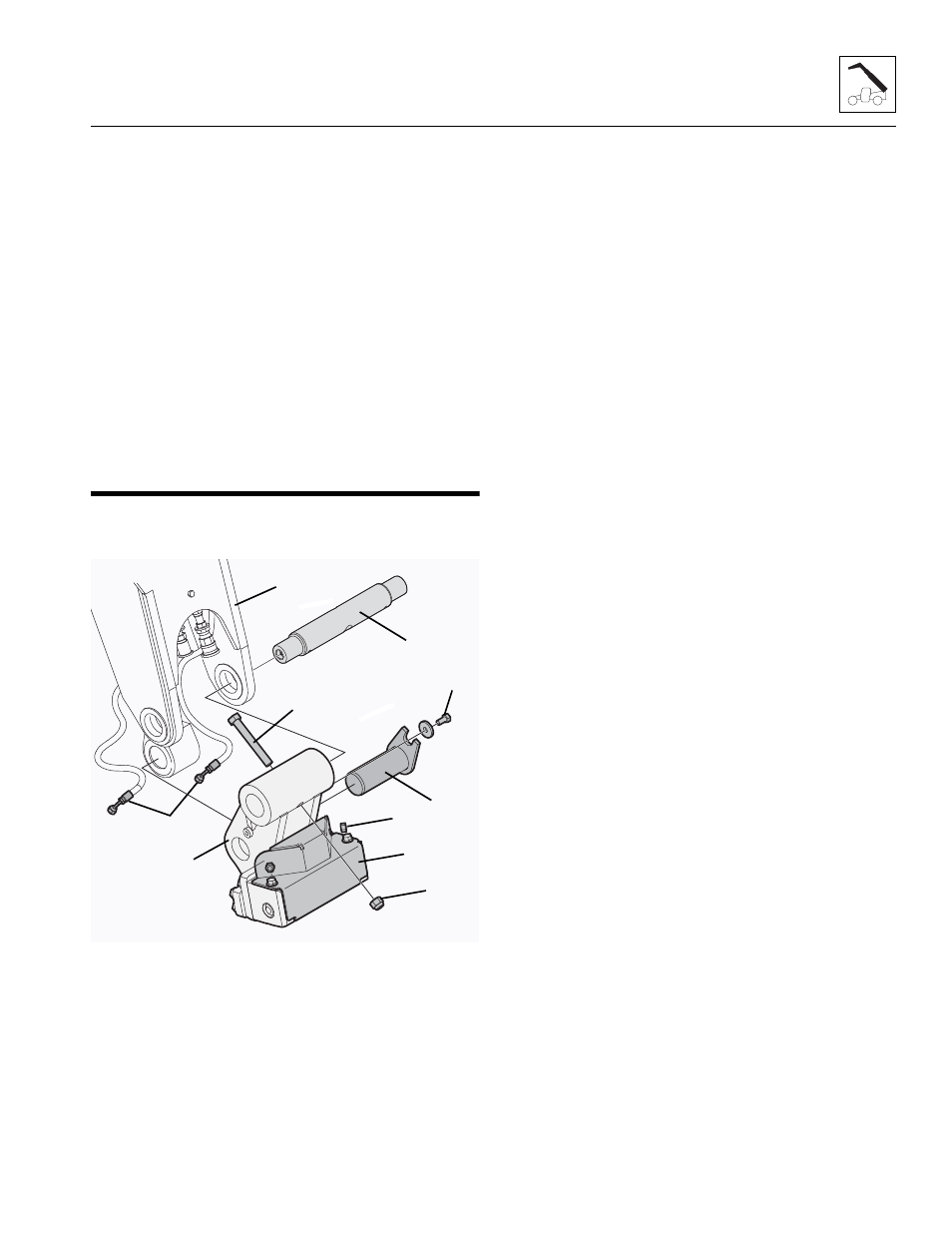

Hydraulic Quick Switch Removal

1. Remove hardware securing cylinder cover (15) and

remove cylinder cover.

2. Remove clamp hardware (16) securing cylinder

cover to hydraulic hoses (17).

3. Label and disconnect hydraulic hoses (17) attached

to quick switch assembly (10). Drain fluid into

suitable container.

4. Plug and cap the hose ends to prevent dirt and

debris from entering the hydraulic system.

5. Remove lock bolt (8) holding tilt cylinder rod end pin

(9) to quick switch assembly (10). Remove tilt

cylinder rod end pin.

6. Support quick switch assembly (10). Remove

capscrew (11) and locknut (12) securing head pin

(13) to boom head (14).

7. Remove the head pin (13) and the quick switch

assembly (10)

8. Inspect above pins for nicks or surface corrosion.

Use fine emery cloth to fix minor nicks or corrosion.

If damaged or if it cannot be repaired pin must

be replaced.Hydraulic Quick Switch Installation

1. Assemble quick switch assembly (10) to boom head

(14). Line up quick switch between mounts on boom

head. The quick switch should be centered in the

boom head.

2. Coat head pin (13) with an anti-seize compound.

Insert head pin through quick switch and boom

head. Secure with capscrew (11) and locknut (12).

3. Align quick switch with tilt cylinder rod end and insert

tilt cylinder rod end pin (9). Align tilt cylinder rod end

pin and screw in locking bolt (8). Torque as required.

4. Uncap and install hydraulic hoses (17) to proper

fittings on quick switch assembly (10). torque

as required.

5. Secure hoses (17) to cylinder cover (15) with clamp

hardware (16).

6. Reinstall cylinder cover (15) with the hardware

removed earlier.

MY7390

13

12

10

11

8

9

14

15

16

17