Operation instructions – Aerovent IM-500 User Manual

Page 8

8

Aerovent IM-500

Operation Instructions

PRIOR TO OPERATION

Although this unit has been assembled and test fired at the

factory, the following pre-operational procedures should

be performed to assure the unit has not been damaged or

misaligned during shipment. This will help assure proper

on-site operation.

1. Remove all shipping straps, braces, and tie-downs.

2. Check burner to insure proper location and if airflow

is moving across burner correctly. The burner may be

wrapped, if so remove wrapping. This is important if

unit was split for shipping convenience. Also check to

be sure sections were caulked when assembled.

3. Check blower and motor sheave alignment, as well as

belt tension.

4. Check bearings for alignment and tightness of mounting

bolts, bolts securing taper lock bushings to shaft, and

that locking collars are secure.

5. Check all electrical connections to insure wires are mak-

ing good contact and are secure in their terminals. Check

tightness of jumpers between terminals.

6. Check gas piping for leaks using a soap/water solution.

After these preliminary checks have been made, the unit

can be prepared for start-up.

Start-Up and Check Out

Each unit is supplied with a service manual which includes

a Field Start-Up Form.

The Field Start-Up Form must

be followed and properly filled out and signed by

the installer. It then is to be mailed or faxed back to

Aerovent, 800 S. High St, Covington OH 45318. The

fax number is (937) 473-3793.

Before continuing with the start-up and checkout proce-

dure,

it is important to familiarize yourself with

the safety controls furnished with the unit.

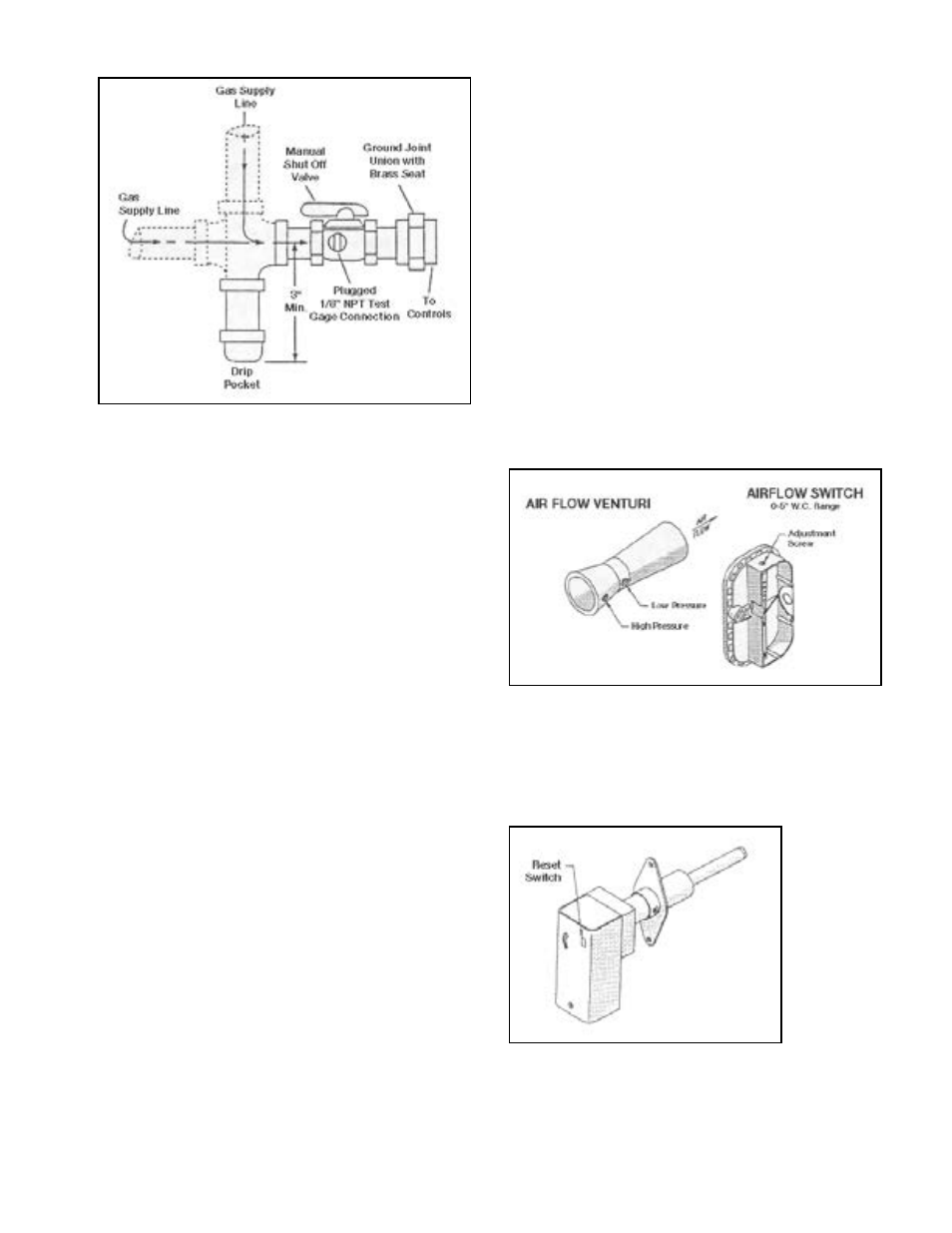

Figure 2. Piping Configuration

Airflow Proving Switch

(Aerovent Part #19240-01)

The airflow proving switch monitors the differential pres-

sure across the venturi sensor located at the burner profile

plate to insure that sufficient airflow exists before allowing

the burner to operate. The airflow proving switch is located

in the gas controls cabinet and is electrically interlocked

with the flame safeguard control system. The air flow

venturi is located at the burner profile plate with pressure

taps leading from that location to the pressure switch. The

venturi amplifies the signal to the pressure sensing device

and minimizes nuisance shutdowns.

High Temperature Limit Control

(Aerovent Part #18756-01E)

The high temperature limit control shuts down the burner

if excessive discharge temperatures are experienced. The

limit control is located in the blower discharge air chamber.

The limit control is electrically interlocked with the flame

safeguard control relay.

Figure 3.

Figure 4. High Temperature Limit