Aerovent IM-175 User Manual

Im-175, Fg7 tubeaxial fans, Roof ventilators

©1997 Aerovent

Fiberglass Reinforced Polyester Fans (FRP)

FG7 Tubeaxial, TF Tubeaxial & TF Vaneaxial Fans

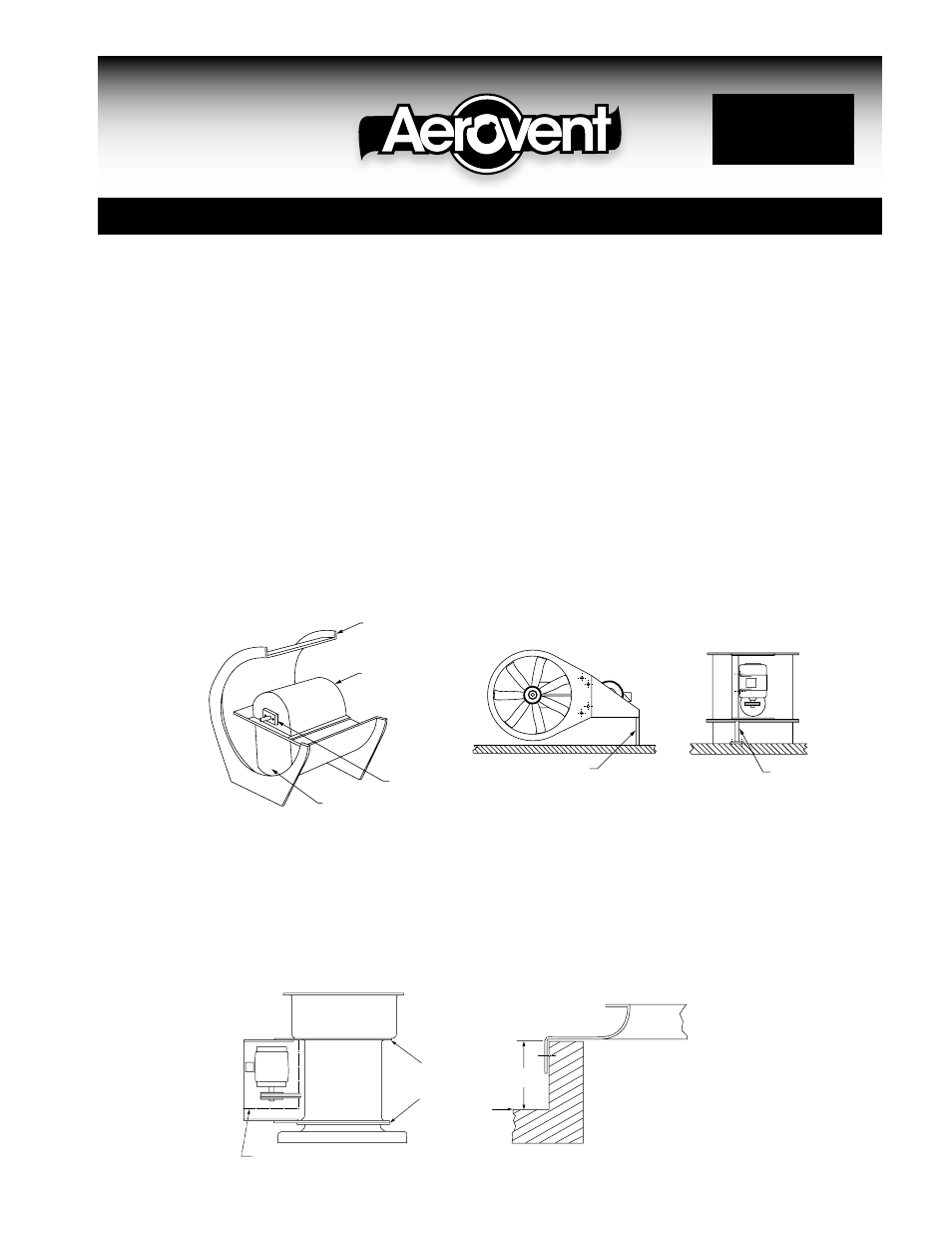

FG7 Tubeaxial Fans

The installation of FRP tubeaxial fans requires some special considerations. The material is very strong and more flexible than steel.

Large FRP fans with heavy motors should not be expected to support themselves by the flange mounting alone. A fan mounted in

the vertical position should not be mounted to support a heavy stack without some reinforcement. It is usually satisfactory to mount

fans having motors up to 3 HP by the flanges alone. Match drill the flanges with the mating duct flange using eight equally spaced

holes,

7

∕

16

" diameter, to accept a

3

∕

8

" bolt. Since fiberglass is used only for corrosion resistance, it is recommended that stainless steel

bolts be used. Use a large washer under the head and nut to increase the load bearing area and do not tighten these to the point of

crushing the flanges. If the fan has a 5 HP or larger motor, it is good practice to attach a brace or hanger rod to the outer edge of

the motor base plate to take some of the weight. If the fan is to be mounted on the roof with a high discharge stack, brace the stack

just above the fan so that not all of the stack weight is carried on the fan mounting flanges.

Accessibility for service and cleaning is a very important consideration when installing an FRP tubeaxial fan. Since these fans are

not available with access doors, the fan should be mounted so it is easily removable for cleaning and service. You may also provide a

section of duct either side of the fan that is removable to provide access.

Fiberglass

Housing

Bearing

Cover

Shaft Seal

Base Support

Support Leg

Support Leg

Horizontal Mount

Vertical Mount

Roof Ventilators

FRP roof ventilators are made in three pieces: the fan section, the curb base and damper section. These have been match drilled

and stainless steel bolts furnished for assembly. The base can be drilled for bolting to the curb and should be caulked or sealed in an

ordinary manner.

If a stack is to be added to raise the height of the discharge, it is recommended that this be placed between the fan and the wind

band damper section. If this is to be exceptionally long (over 10 feet of ordinary fiberglass construction), bracing should be provided

to take some of the weight of the stack section off of the ventilator fan and base assembly.

Damper Section

Fan

Curb Base

Field Procedure:

Caulk ventilator at

assembly where

indicated to prevent

leakage.

6"

Min.

Roof

Curb

Caulk

Seam

Roof

Line

Curb Base

SUGGESTED

MOUNTING

Motor Cover

General Installation, Operation and Maintenance Instructions For Aerovent Products

IM-175

June 1997