Aerovent IM-500 User Manual

Page 7

7

Aerovent IM-500

11. Purge air from gas piping before lighting unit.

12. After air has been purged, check for gas leaks in the

piping system using a soap water solution.

13. Install a ground joint union and gas cock external of

the unit for easy servicing of controls.

14. Allow at least 5 feet of piping between any high pres-

sure regulator and the unit control pipe train.

Gas Supply Pressure – 5 lbs. or less

The Aerovent air make-up unit is standardly furnished with

the Maxitrol modulating system. This device controls the

firing rate of the burner to maintain the desired operating

temperature.

It functions as a regulator and modulator which will not

allow the burner manifold pressure to exceed that which

produces the maximum firing rate, and also will reduce the

pressure below this value to modulate the burner through-

out the normal 25 to 1 turn down ratio. The upstream

pressure supplied to the unit pipe train must not exceed 5

pounds. This is the maximum for suitable operation. The

minimum operating pressure will vary depending upon the

unit size and pipe train size. This pressure is marked on

the pressure gauge. As long as the gas pressure supplied to

the unit is maintained at some value between the minimum

as marked on the gauge and 5 pounds maximum, the air

make-up unit will perform at its rated capacity.

If the gas supply system is designed for a pressure

higher than 5 pounds, it is necessary to install an additional

regulator upstream of the connection to the unit. See fol-

lowing instructions for gas supply over 5 pounds.

The downstream pressure from the line regulator will

vary somewhat depending upon the firing rate of the air

make-up unit. Variations can also be caused by other gas

equipment connected to the distribution system. It is neces-

sary, therefore, to be sure that the setting of the supply line

regulator is such that the pressure supplied to the unit will

always be at least equal to the minimum and not exceeding

5 psi.

NOTE:

DO NOT VENT THE VENT VALVE AND PRESSURE

REGULATOR IN THE SAME VENT PIPE. SEPARATE

VENT LINES TO OUTSIDE ATMOSPHERE MUST

BE RUN FOR THE UNIT TO OPERATE PROPERLY.

COMBINING THE VENT LINES TO ATMOSPHERE

WILL CAUSE THE HIGH LIMIT GAS PRESSURE

CONTROL TO LOCK OUT THE FLAME SAFETY

SYSTEM AND SHUT DOWN THE UNIT.

NOTE:

A PRESSURE REGULATOR MAY BE REQUIRED TO

MEET THE STATE OR LOCAL CODE. CONSULT

YOUR STANDARDS.

Gas Supply Pressure – Over 5 lbs.

When the supply line pressure to an air make-up unit

exceeds 5 pounds or may at times fluctuate above 5 pounds,

it is necessary to install a line pressure regulator ahead of

the input to the air make-up unit. The size must be selected

to handle the maximum capacity of the unit, and the type

of regulator selected to work at the maximum inlet pressure

and having a capability of maintaining the outlet pressure

at some value between 8 ounces and 5 pounds. As a rule,

the outlet pressure from the line pressure regulator may be

adjusted anywhere between 2 and 4 pounds. If the regula-

tor was furnished by Aerovent, it has been sized according

to the information in the original order and shown on the

parts list. Regulators are sized according to capacity and

pressure and not according to pipe size; therefore, the size

of the pipe at the inlet to the air make-up unit may not be

the same as the pipe size of the regulator.

To be sure the supply line is properly sized, it is sug-

gested that the representative of the local gas company be

consulted about pipe sizing. The line regulator should be

installed close to the air make-up unit. There should be no

elbows, couplings, valves, or fittings within at least ten pipe

diameters of the inlet and the discharge of the pressure

regulator. A shut-off cock should be placed upstream of

the regulator so that it can be removed for servicing if nec-

essary. It is a good idea, also, to install a pressure gauge on

the upstream side having a scale range sufficient to indicate

the supply line pressure.

It is very important to connect the regulator vent with

pipe or tubing extended to the outside with the end pro-

tected from the weather. Do not vent the regulator into the

air make-up unit or the duct system, or near the inlet to the

air make-up unit.

NOTE:

DO NOT VENT THE VENT VALVE AND PRESSURE

REGULATOR IN THE SAME VENT PIPE. SEPARATE

VENT LINES TO OUTSIDE ATMOSPHERE MUST

BE RUN FOR THE UNIT TO OPERATE PROPERLY.

COMBINING THE VENT LINES TO ATMOSPHERE

WILL CAUSE THE HIGH LIMIT GAS PRESSURE

CONTROL TO LOCK OUT THE FLAME SAFETY

SYSTEM AND SHUT DOWN THE UNIT.

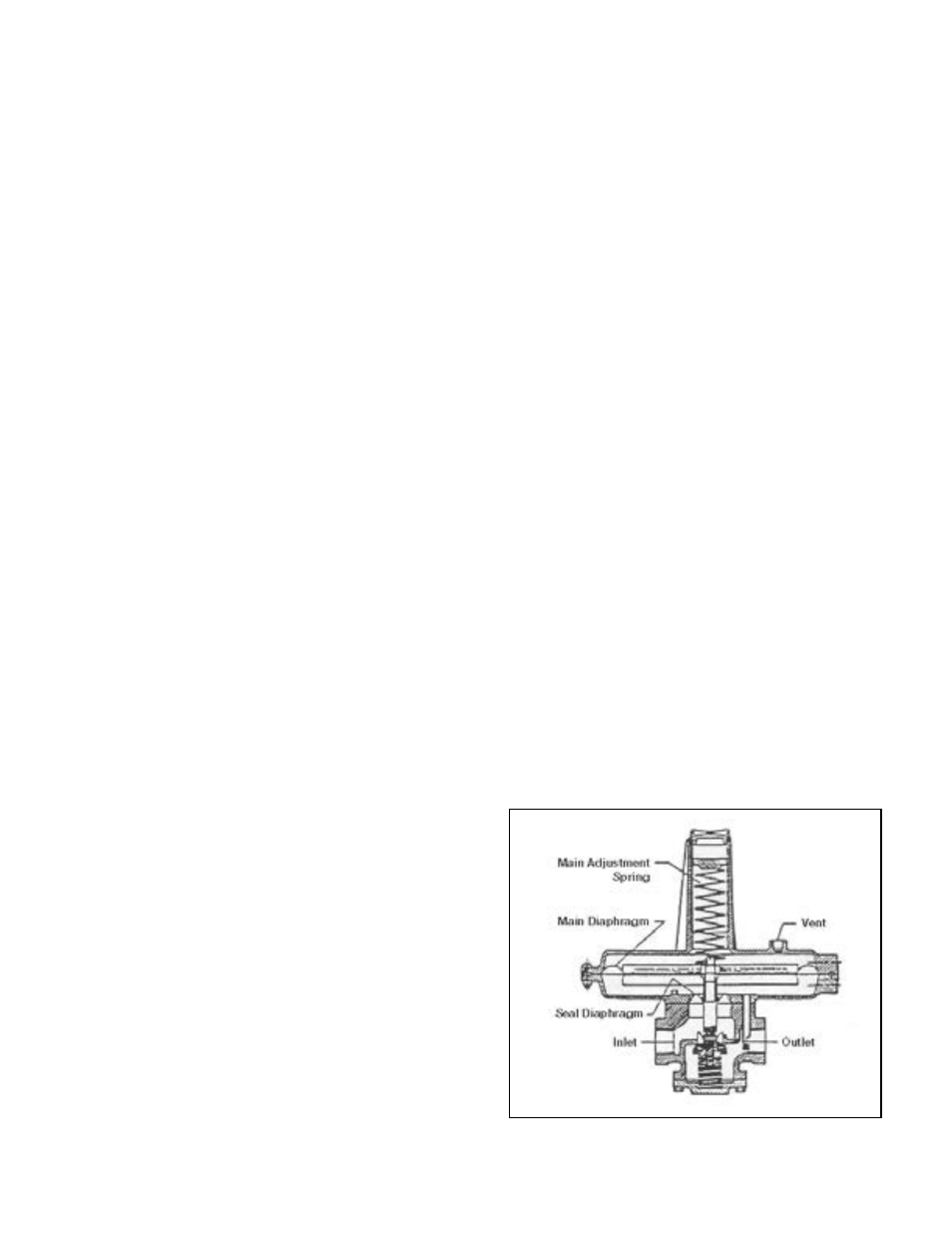

Figure 1. Typical Gas Regulator