Reventative, Aintenance, Chedule – Snorkel Bi-Energy-sn4275+ User Manual

Page 19: A i l y, H e c k, I s t

Preventative Maintenance Schedule

067449-023 LX31/LX41 Electric and BiEnergy

Operator Manual

Page 17

P

REVENTATIVE

M

AINTENANCE

S

CHEDULE

The complete inspection consists of periodic visual and operational checks, along with periodic minor

adjustments to assure proper performance. Daily inspection will prevent abnormal wear and prolong the

life of all systems. The inspection and maintenance schedule is to be performed at regular intervals.

Inspection and maintenance shall be performed by personnel who are trained and familiar with mechanical

and electrical procedures.

W A R N I N G

!

!

Before performing preventative maintenance, familiarize yourself with the operation of the machine.

Always block the elevating assembly whenever it is necessary to enter the scissor assembly to perform

maintenance while the platform is elevated (see page 14).

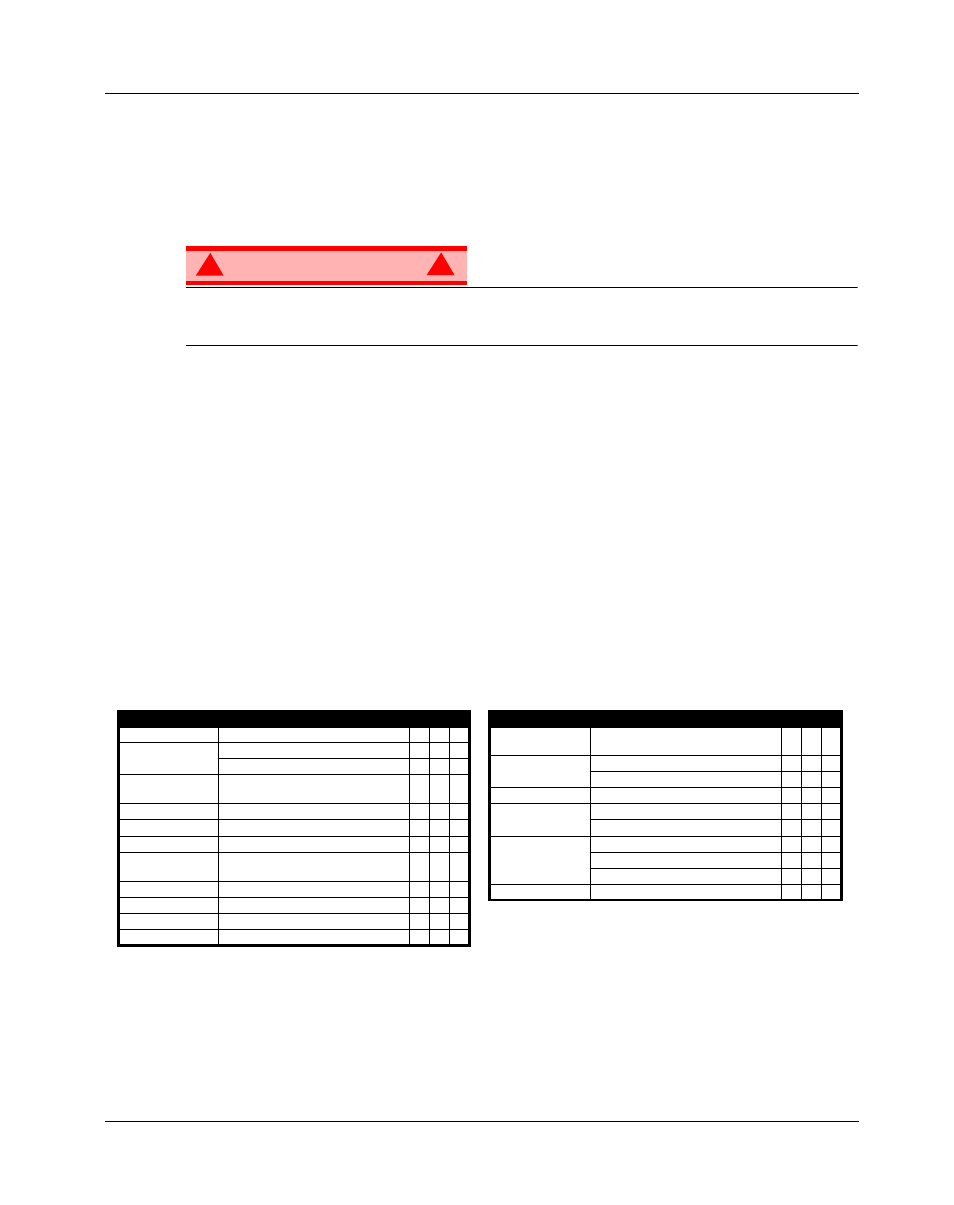

The daily preventative maintenance table has been designed for machine service and maintenance repair.

Please photocopy the Daily Preventative Maintenance Check List and use the table as a checklist when

inspecting the machine for service.

D

A I L Y

P

R E V E N T A T I V E

M

A I N T E N A N C E

C

H E C K

L

I S T

\

M

AINTENANCE

T

ABLE

K

EY

Y = Yes/Acceptable

N = No/Not Acceptable

R = Repaired/Acceptable

M

AINTENANCE

R

EPORT

Date: _______________________________________

Owner: _____________________________________

Model No: ___________________________________

Serial No: ___________________________________

Serviced By: _________________________________

COMPONENT

INSPECTION OR SERVICES

Y

N

R

Batteries

Check electrolyte level

Chassis

Check hoses for pinch or rubbing points

Check welds for cracks

Control Cable

Check the exterior of the cable for pinching,

binding or wear

Controller

Check switch operation

Drive Motors

Check for operation

Elevating Assembly

Inspect for structural cracks

Emergency Lowering

System

Operate the emergency lowering valve and

check for serviceability

Entire Unit

Check for and repair collision damage

Hydraulic fluid

Check fluid level

Hydraulic Pump

Check for hose fitting leaks

Hydraulic System

Check for leaks

Labels

Check for peeling, missing, or unreadable

labels & replace

Platform Deck and

Rails

Check welds for cracks

Check condition of deck

Tires and Wheels

Check for damage

Engine Oil and Filter

Check level and condition

Check for leaks

Engine Fuel System

Check fuel level

Check for leaks

Check air cleaner

Engine Coolant

Check coolant level (with engine cold)

COMPONENT

INSPECTION OR SERVICES

Y

N

R