Goulds Pumps 3393 - IOM User Manual

Page 98

Maintenance

13. Tighten the bearing locknut (136A) until resistance is felt when rotating the bearing outer

races in opposite directions by hand. See illustration.

14. Replace the bearing bracket (228C) and align with the shaft (122) and seal chamber (184).

15. Reinstall and tighten nuts (425) to proper torque values.

16. Position bearing housing o-ring (412) and reinstall bearing housing cover (119) with cap

screws (371C) and tighten to correct torque values.

The drain hole in the isolator must be at bottom dead center when the pump is in the

horizontal position. Use Loctite® thread sealant 5699 or equal when installing the cap

screws.

17. Replace cooling fan (392) if applicable.

18. Refit the seal guards.

19. Rotate shaft (122) to see that it turns smoothly.

20. Reorient the assembly 180

O

so that the discharge casing is down and the shaft extends

up.

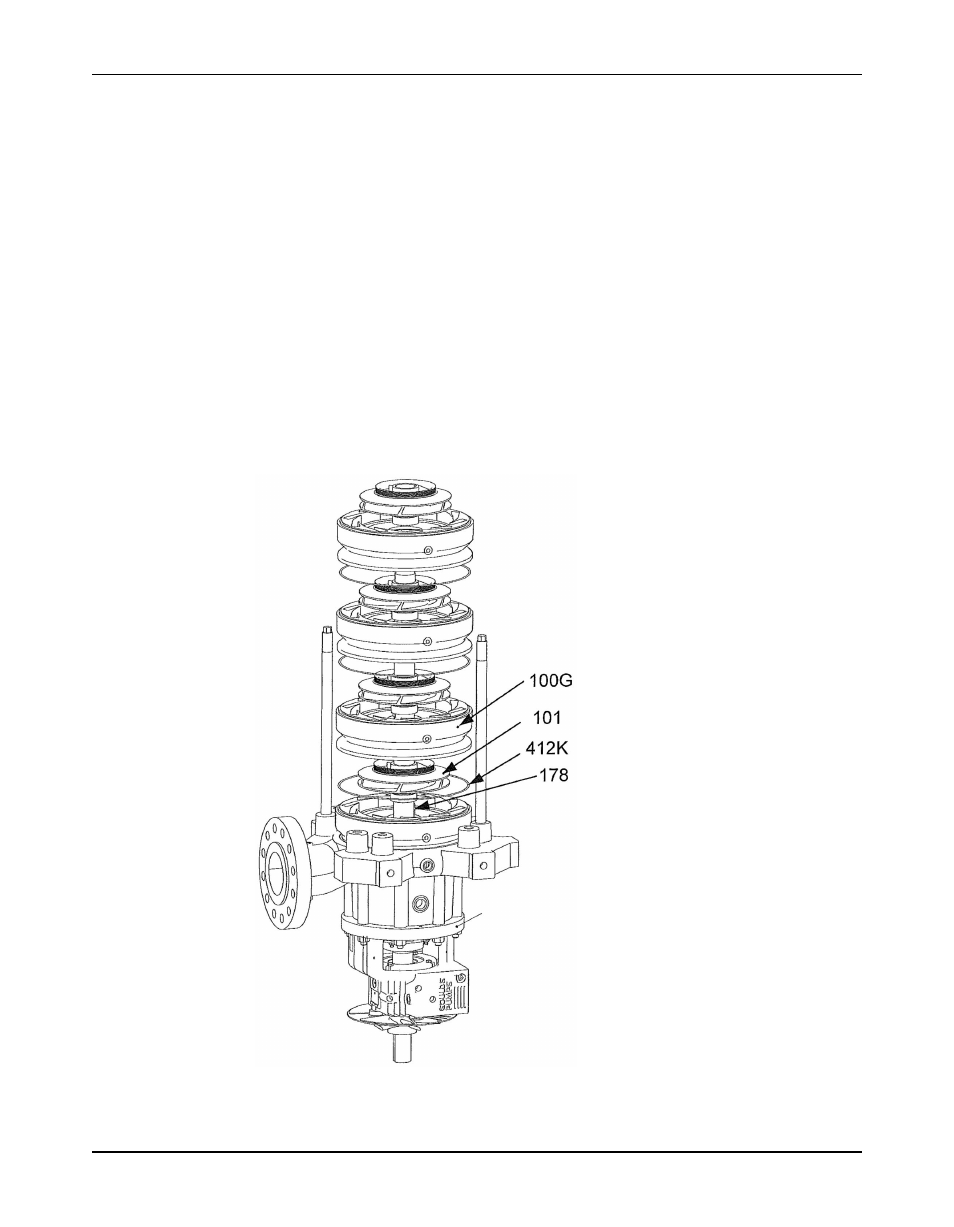

21. Install last stage impeller (101) and key (178) into discharge casing (100D). Any impeller

wear rings should have been installed first.

22. Install final stage piece (100H) and discharge casing o-ring (497D) and secure against

discharge casing. Casing and stage piece wear rings should be installed prior to this step

23. Install remaining impellers (101), impeller keys (178), stage casings (100G) and stage

casing o-rings (412K). Impellers should all butt up against one another.

96

Model 3393 Installation, Operation, and Maintenance Manual