Purge oil mist, Lubricate the bearings after a shutdown period, Shaft sealing with a mechanical seal – Goulds Pumps 3393 - IOM User Manual

Page 43

Commissioning, Startup, Operation, and Shutdown

2. Check that the oil level is correct. The correct oil level is centered in the bullseye sight

glass, when the pump is not in operation. During operation, bullseye sight gives a false oil

level reading.

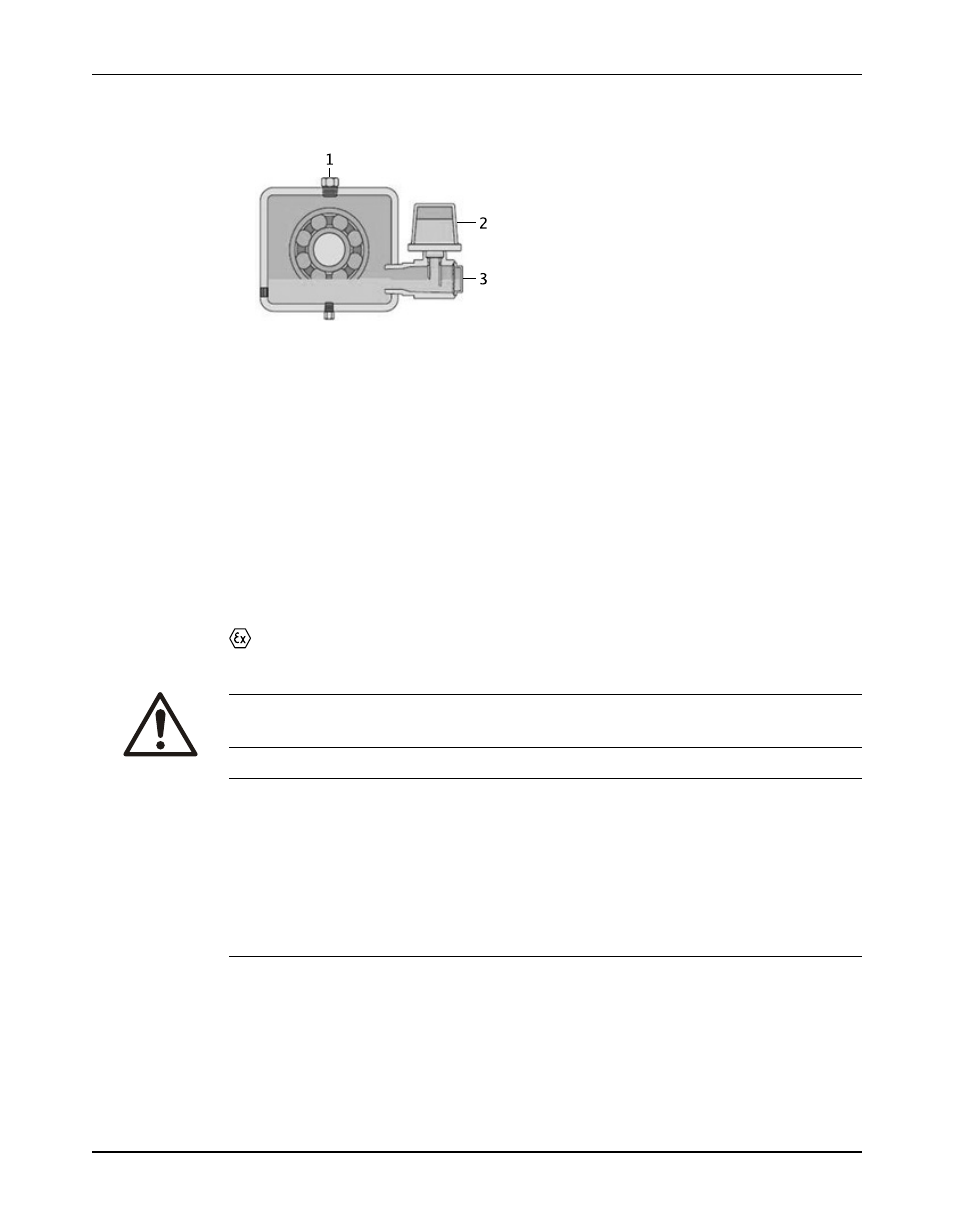

1. Plug

2. Reservoir

3. Main body

Purge Oil Mist

The 3393 can be modified for purge oil mist lubrication. Consult a factory representative for

details.

Lubricate the bearings after a shutdown period

1. Flush out the bearings and bearing frame with a light oil to remove contaminants.

During flushing, make sure to rotate the shaft slowly by hand.

2. Flush the bearing housing with the proper lubricating oil to ensure oil quality after cleaning.

3. Refer to "Reassembly" section for proper bearing greasing procedure.

Shaft sealing with a mechanical seal

The mechanical seal used in an ATEX classified environment must be properly certified.

Precautions

WARNING:

The mechanical seal used in an ATEX or Ex-classified environment must be properly certified. Prior to

startup, make sure that all areas that could leak pumped fluid to the work environment are closed.

NOTICE:

• The mechanical seal must have an appropriate seal-flush system. Otherwise, excess heat

generation and seal failure can occur.

• Cooling systems such as those for bearing lubrication and mechanical-seal systems must

be operating properly to prevent excess heat generation, sparks, and premature failure.

• Sealing systems that are not self-purging or self-venting, such as plan 23, require manual

venting prior to operation. Failure to do so will result in excess heat generation and seal

failure.

Shipping

Pumps may be shipped with or without a mechanical seal installed.

Cartridge-type mechanical seals

Cartridge-type mechanical seals are commonly used. Cartridge seals are preset by the seal

manufacturer and require no field settings. Cartridge seals installed by the user require

Model 3393 Installation, Operation, and Maintenance Manual

41