Radial suction pump - item 112 (ball bearing) – Goulds Pumps 3393 - IOM User Manual

Page 85

Maintenance

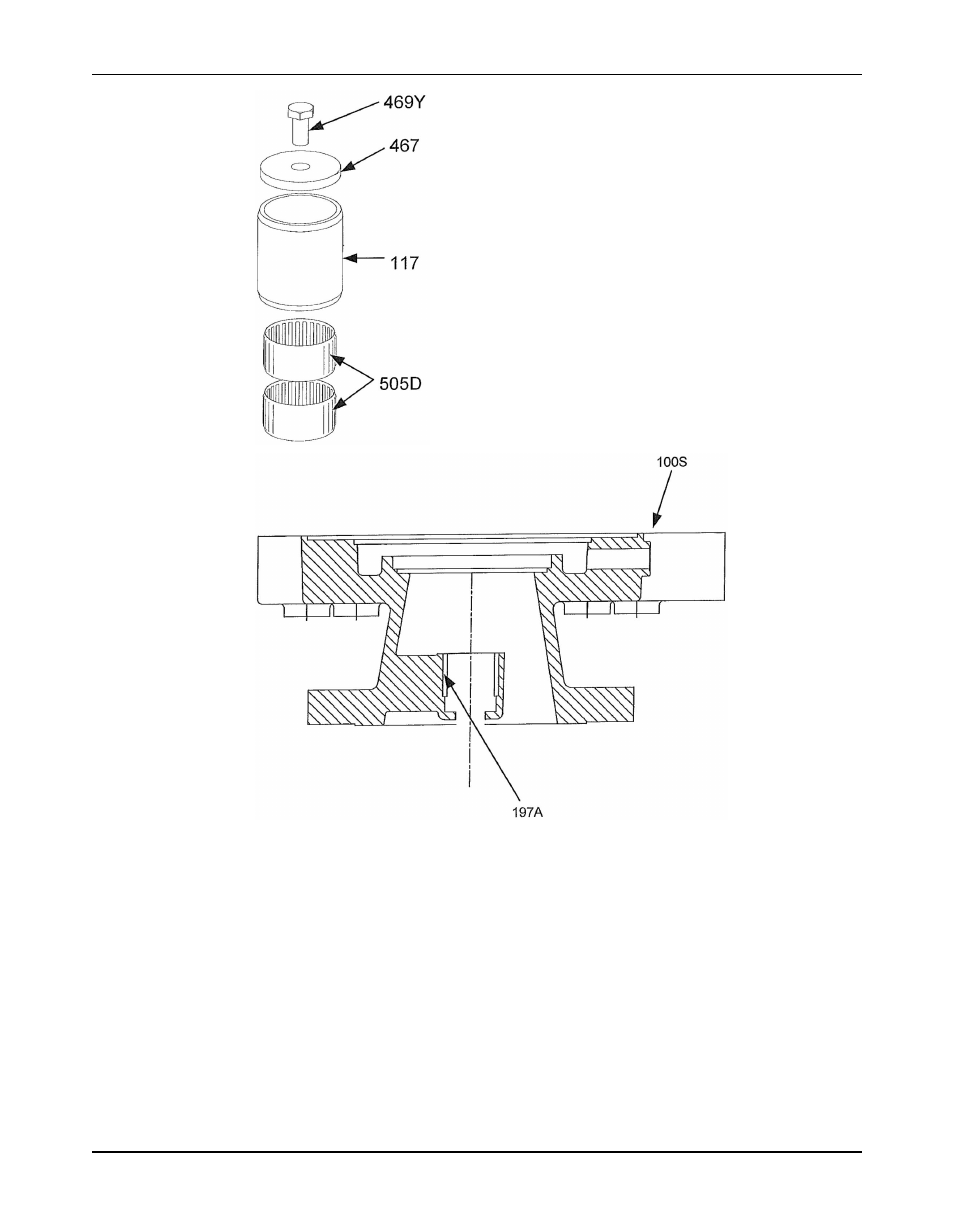

Radial suction pump - item 112 (ball bearing)

1. Clean and lubricate the fitting surfaces between the bearing bracket (228C) and discharge

casing 110D).

2. Position the bearing cover (119) with the bearing isolator (333A) over the shaft.

3. Verify that the bearing spacer (157) is in place against the shaft shoulder.

4. Preheat the new bearing (112) (max. 230ºF) and slide onto the shaft (122).

5. Replace bearing lockwasher (382) and bearing nut (136A).

6. Allow the bearing (112) to cool to room temperature.

7. Tighten the bearing locknut (136A) until resistance is felt.

8. Replace the bearing housing (228C) and align with the shaft (122) and seal chamber (184).

9. Reinstall and tighten nuts (425) to proper torque values.

10. Install the bearing cover (119) to the bearing housing with cap screws (371C) and tighten to

correct torque values. NOTE: the drain hole in the isolator must be at bottom dead center

when the pump is in the horizontal position.

11. Connect flush piping to gland.

Model 3393 Installation, Operation, and Maintenance Manual

83