Goulds Pumps 3393 - IOM User Manual

Page 122

Appendix

3. Bring nuts up evenly by hand with a wrench

4. Snug nuts with wrench by hand to approx. 20 to 30 ft-lb.

5. Mount suction and discharge casing feet in final location.

6. Place liquid end assembly horizontally on a milled surface (the baseplate supplied with the

pump can be used).

7. Check flatness of casing feet against the milled surface with a feeler gauge. If not flat,

carefully and evenly loosen the four tie bolt nuts just enough to allow the casing feet to be

moved so they are flat on the milled surface of the table. Variation is to be ≤ 0.003 in. If

greater than 0.003 in, reface to meet requirements or replace casing feet.

8. Once the feet are flat on the table, retighten tie rod nuts 1 thru 4 in the manner defined

above.

9. Tighten tie rod nuts 5 thru 8 in the same manner.

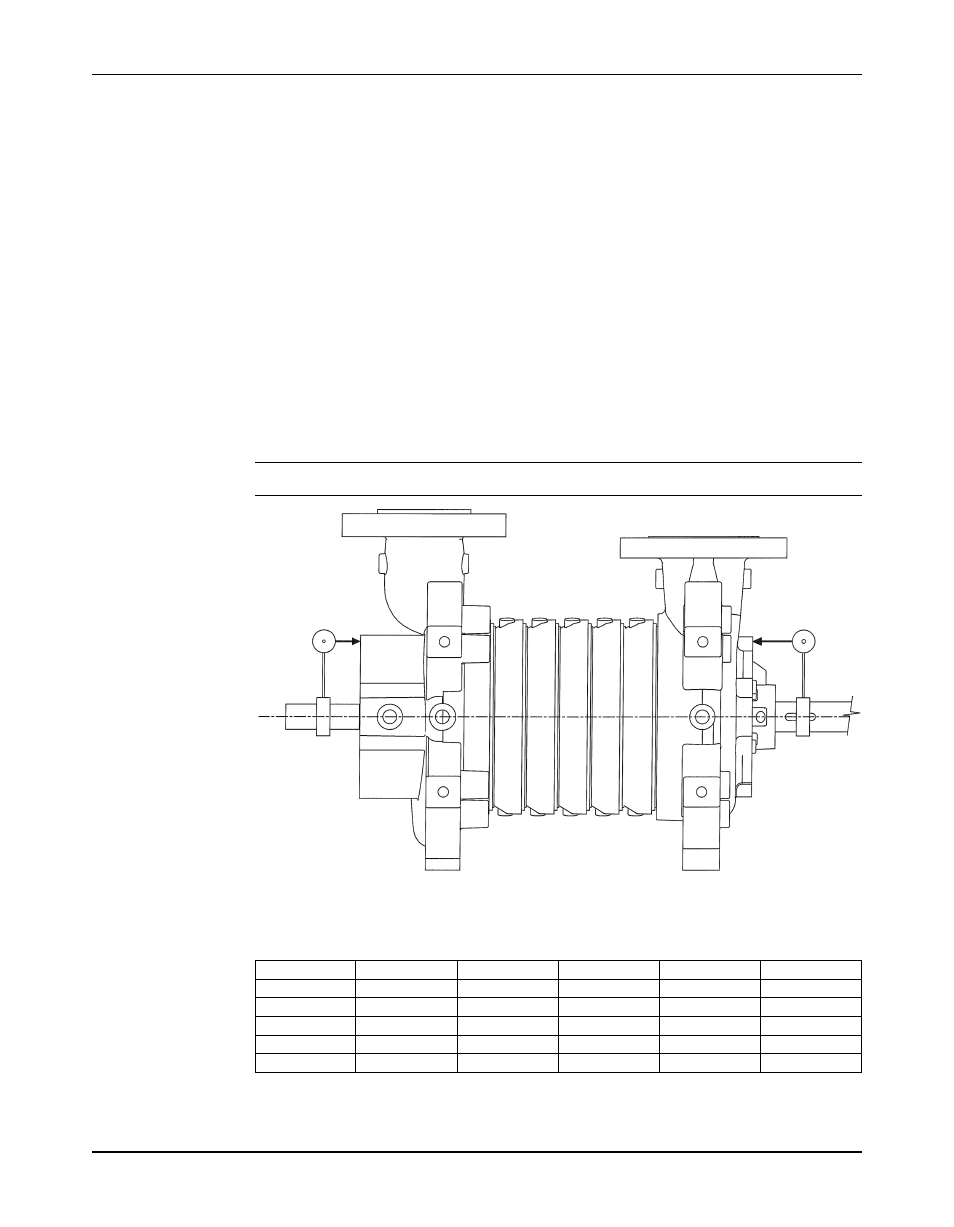

10. Tighten all eight tie rod nuts in sequence shown in Figure above by hand with torque

wrench to approximately 50 ft-lb.

11. Mount dial indicators to shaft, measure and record the bearing housing face run-out on the

suction and discharge casings (see sketch below). If any readings exceed 0.005 in, stop

and address the issue. Note: Because there are no bearings mounted at this time, the shaft

will need to be pushed inward from the discharge end until it stops. Set the gauges to zero

and record the readings every 90

o

.

NOTICE:End suction pumps will only have a reading on the discharge side.

12. Using a torque wrench, torque the tie rod nuts in the following three increments using the

sequence shown in Figure above: a. 100 ft-lb. b. 50% of full torque (if applicable). c. 100%

of full torque.

Table 13:

English Units

Metric Units

Model

Size (mm)

50% ft-lb

100% ft-lb

50% N-m

100% N-m

2.5x4-8 (65)

20x2.5

N/A

163

N/A

221

4x5-10 (100)

24x3

140

281

191

381

5x6-11 (125)

30x3.5

280

559

379

758

6x8-13 (150)

36x4

488

976

662

1324

13. Re-check flatness of casing feet against the milled surface with a feeler gauge. Max

variation is to be ≤ 0.003 in.

120

Model 3393 Installation, Operation, and Maintenance Manual