Mechanical-seal maintenance, Disassembly, Introduction – Goulds Pumps 3393 - IOM User Manual

Page 52

Maintenance

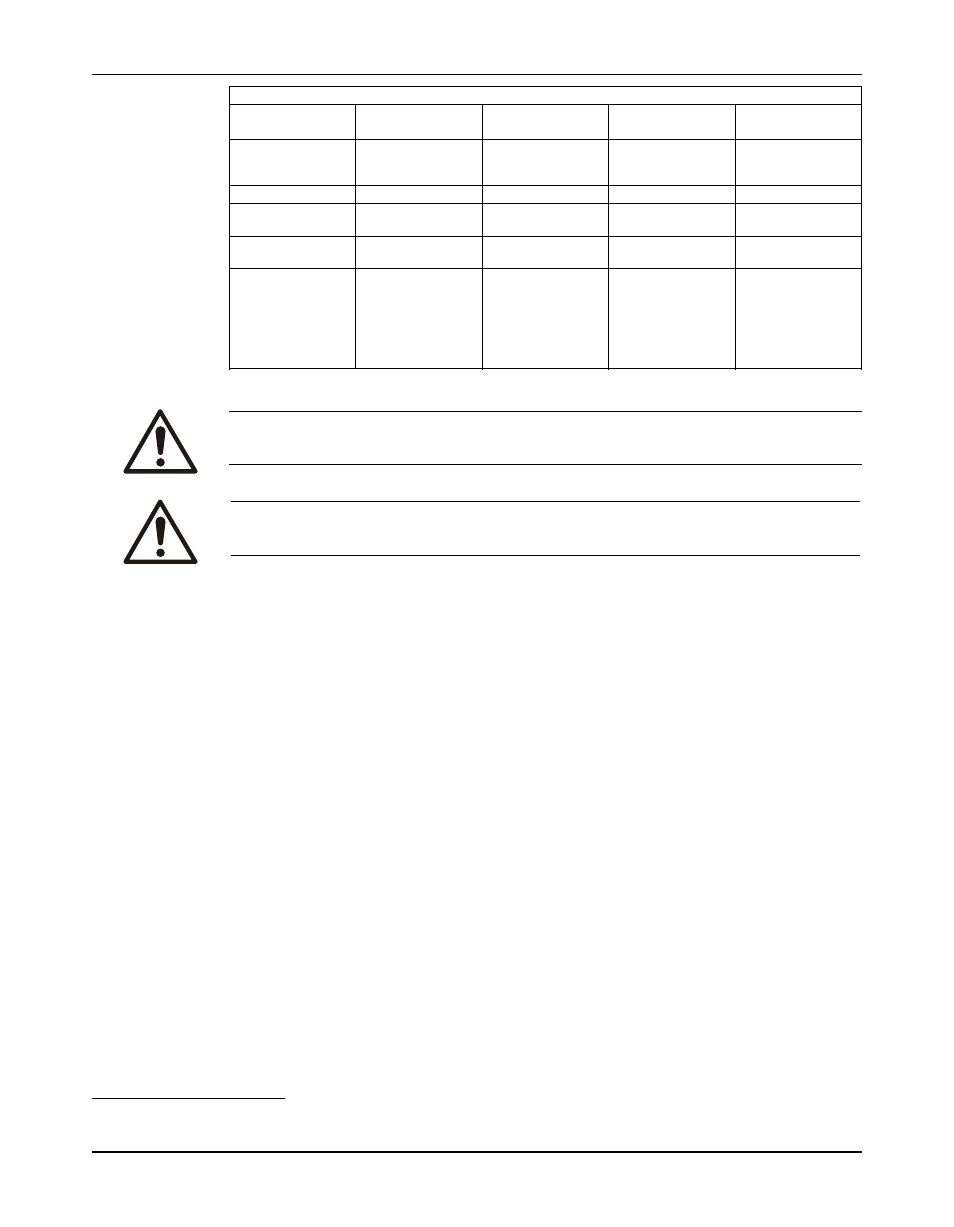

3393 Ball Bearings

Pump size

2.5x4-8

4x5-10

5x6-11

6x8-13

2.5x5-8

4x6-10

5x8-11

5x10-13

Initial Fill per Bear-

3.4 / 1.6

3.4 / 1.6

5.3 / 2.5

5.3 / 2.5

ing Housing - Oil

(US pt, l)

Bearing - Driver End

7408 BCBM

7409 BCBM

7311 BECBM

7214 BECBM

Bearing - Outboard

SiC/SiC

SiC/SiC

SiC/SiC

SiC/SiC

(ES)

2

Bearing - Outboard

6408

6409

6311

6214

(RS)

Maximum permis-

180 / 82

180 / 82

180 / 82

180 / 82

sible surface tem-

perature measured

at the 12 o'clock

(top of bearing

housing) position

(

O

F,

O

C)

Mechanical-seal maintenance

WARNING:

The mechanical seal used in an ATEX or Ex-classified environment must be properly certified. Prior to

startup, make sure that all areas that could leak pumped fluid to the work environment are closed.

CAUTION:

Never operate the pump without liquid supplied to mechanical seal. If you run a mechanical seal dry,

even for a few seconds, this can cause seal damage. Physical injury can occur if a mechanical seal fails.

Cartridge-type mechanical seals

Cartridge-type mechanical seals are commonly used. Cartridge seals are preset by the seal

manufacturer and require no field settings. Cartridge seals installed by the user require

disengagement of the holding clips prior to operation, allowing the seal to slide into place. If the

seal has been installed in the pump by ITT, these clips have already been disengaged.

Other mechanical seal types

For other types of mechanical seals, refer to the instructions provided by the seal manufacturer

for installation and setting.

Before you start the pump

Check the seal and all flush piping.

Disassembly

Introduction

The section on disassembly will address the bearings, mechanical seal, balance drum and

balance drum stator as well as the complete pump. Where the disassembly is the same for end

and radial suction pumps, no distinction will be made. When the disassembly is different, it will

be identified for either end or radial suction configuration.

2

Product lubricated bearing

50

Model 3393 Installation, Operation, and Maintenance Manual