Tie-rod torque specifications and procedure – Goulds Pumps 3393 - IOM User Manual

Page 120

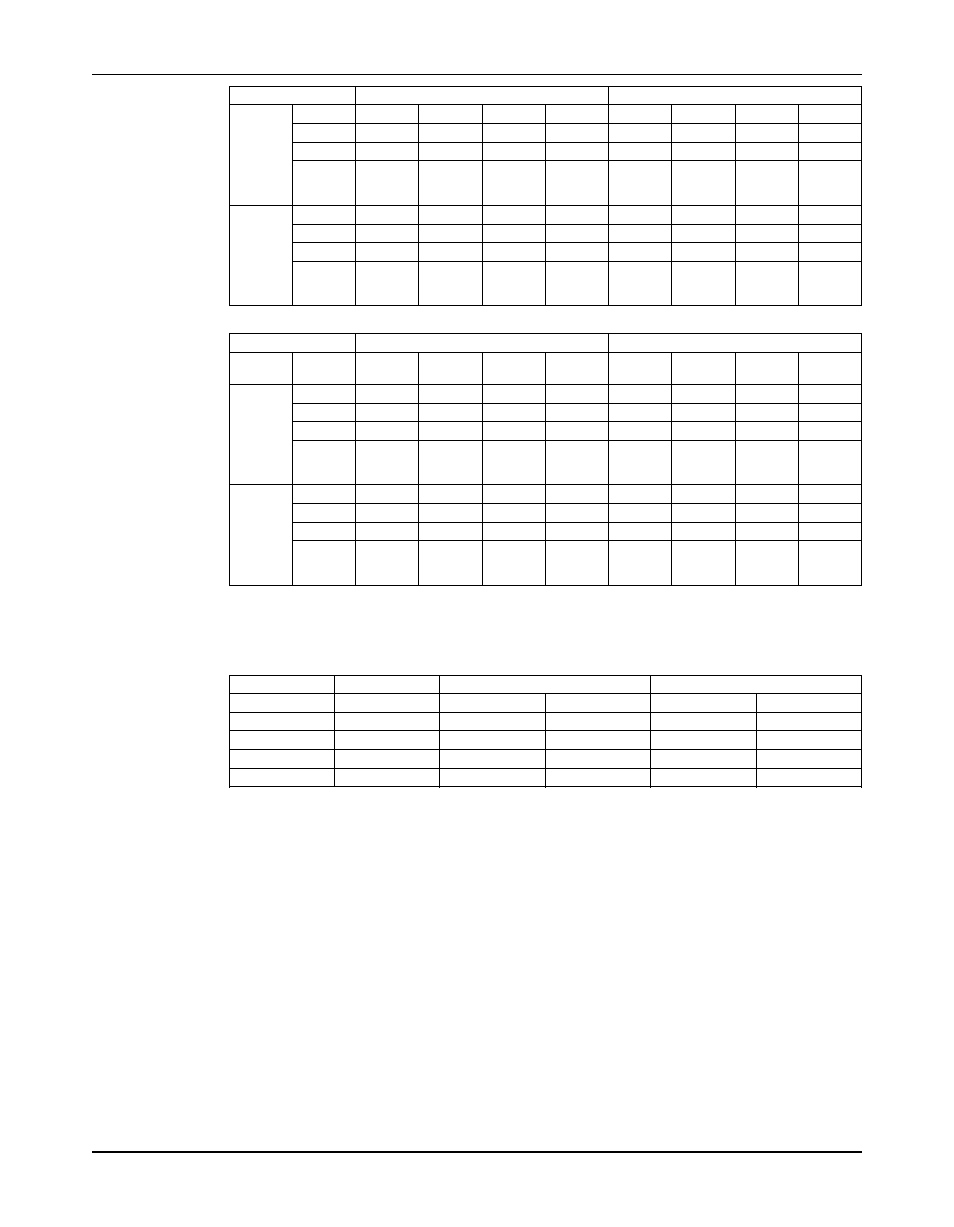

Appendix

Forces (lbf)

Moments (ft-lbs)

Vertical

2.5

200

165

250

360

520

260

395

705

nozzle

4

320

260

400

570

980

500

740

1330

perpen-

5

440

360

550

790

1340

685

1020

1820

dicular to

the shaft 6

560

460

700

1010

1700

870

1300

2310

(ES and

RS)

Hoizon-

2.5

200

165

250

360

520

260

395

705

tall noz-

4

320

400

260

570

980

500

740

1330

zle per-

5

440

550

360

790

1340

685

1020

1820

pendicu-

lar to the 6

560

700

460

1010

1700

870

1300

2310

shaft (ES

and RS)

Table 12: Discharge Nozzle Configuration (Metric units)

Forces (N)

Moments (Nm)

Flange

Fx

Fy

Fz

Σ F

Mx

My

Mz

Σ M

Size (in)

Vertical

2.5

890

734

1112

1601

705

352

535

955

nozzle

4

1423

1156

1779

2535

1328

678

1003

1802

perpen-

5

1957

1601

2446

3514

1816

928

1382

2466

dicular to

the shaft 6

2491

2046

3114

4492

2304

1179

1762

3130

(ES and

RS)

Hoizontal 2.5

890

734

1112

1601

705

352

535

955

nozzle

4

1423

1779

1156

2535

1328

678

1003

1802

perpen-

5

1957

2446

1601

3514

1816

928

1382

2466

dicular to

the shaft 6

2491

3114

2046

4492

2304

1179

1762

3130

(ES and

RS)

Tie-Rod Torque Specifications and Procedure

Appendix D

Model

Size (mm)

English units

Metric units

50% ft-lb

100% ft-lb

50% N-m

100% N-m

2.5x4-8 (65)

20x2.5

N/A

163

N/A

221

4x5-10 (100)

24x3

140

281

191

381

5x6-11 (125)

30x3.5

280

559

379

758

6x8-13 (150)

36x4

488

976

662

1324

Mark casings as shown below and apply torque values in this sequence or as noted in the

instructions below.

118

Model 3393 Installation, Operation, and Maintenance Manual