Pump description – Goulds Pumps 3393 - IOM User Manual

Page 16

Product Description

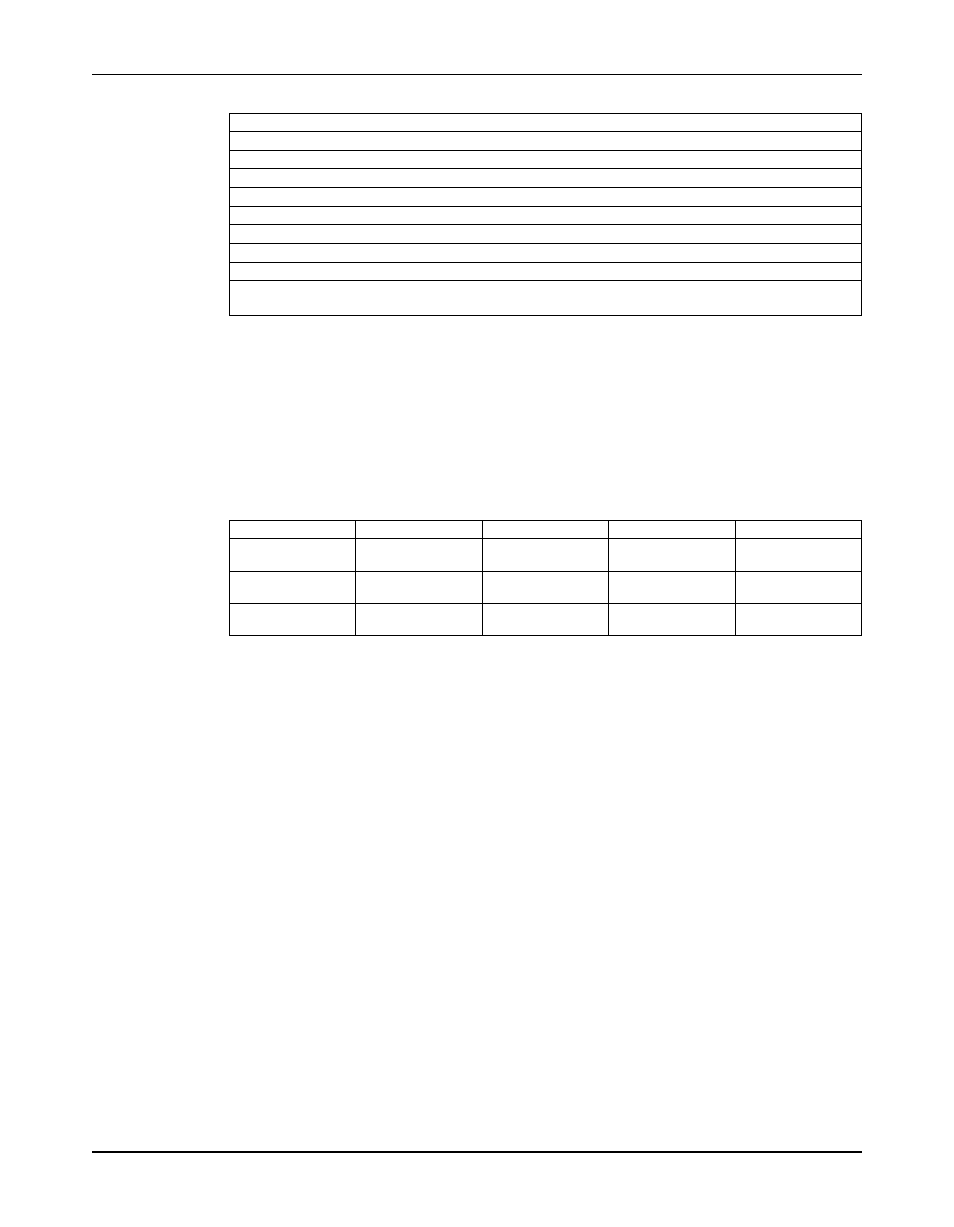

Flange ratings

Flange Options

Suction

ANSI B16.5 150 lb RF / ISO 7005-1 PN 20

ANSI B16.5 300 lb RF / ISO 7005-1 PN 50

EN 1092-1 PN 40

Discharge

EN 1092-1 PN 63

ANSI B16.5 600 lb RF / ISO 7005-1 PN 110

EN 1092-1 PN 100

ANSI B16.5 900 lb RF / ISO 7005-1 PN 150

(12 Chrome casing only)

Impeller

The impeller is a single suction, enclosed impeller. It is keyed to the shaft.

Seal chamber

The seal chamber accepts single or double cartridge seals and various piping plans. It is

dimensioned based on DIN 24960.

Bearing frame and bearings

The bearing frame is cast iron, finned for additional cooling and oil lubricated. Bearings are as

noted in the following table.

Pump Size

2.5x4-8

4x5-10

5x6-11

6x8-13

Bearing - driver end 7408 BCBM

7409 BCBM

7311 BECBM

7214 BECBM

(thrust)

Bearing - outboard

SiC/SiC

SiC/SiC

SiC/SiC

SiC/SiC

(ES) (radial)

Bearing - outboard

6408

6409

6311

6214

(RS) (radial)

Shaft

The shaft is of heavy-duty construction of 17-4 pH or super duplex depending on the casing

material. It is designed for cartridge mechanical seals to limit shaft deflection to .002 in. (0.051

mm) at worst case condition.

Baseplate

The baseplate is of fabricated steel and supports the pump, driver, and any accessories.

Pump description

The Goulds Model 3393 is a radially split, segmented casing, multistage pump designed with

modular interstage components. These identical components can be assembled to produce

pumps of varying numbers of stages, hydraulics, materials, and configurations to meet the

customer's specific requirements. Its multiple suction nozzle and discharge nozzle orientations

allow the 3393 to adapt to multiple piping installations and provide the piping designer with

flexibility in plant layout. Multiple hydraulics for each pump size optimize efficiency across a

vast range of applications. All intermediate stage components are identical which reduces

spare parts inventory.

The 3393 is designed as a two-pole speed pump. There will be times when the pump will be

operated at variable speed. The 3393 can be operated between 2700 and 3600 rpm without

reference to the factory. At speeds above 3600 rpm and below 2700 rpm, a lateral critical

speed analysis must be conducted by the factory. Contact your local representative for pricing.

In all cases it is imperative that the pump be brought up to its minimum operating speed as

quickly as possible. This ramp up time should not exceed 5 seconds.

14

Model 3393 Installation, Operation, and Maintenance Manual