Oil volumes, Lubricating oil requirements, Lubricate the bearings with oil – Goulds Pumps 3393 - IOM User Manual

Page 42

Commissioning, Startup, Operation, and Shutdown

However. the oiler can be installed on either side of the bearing housing so it should be put

where it is most easily accessible.

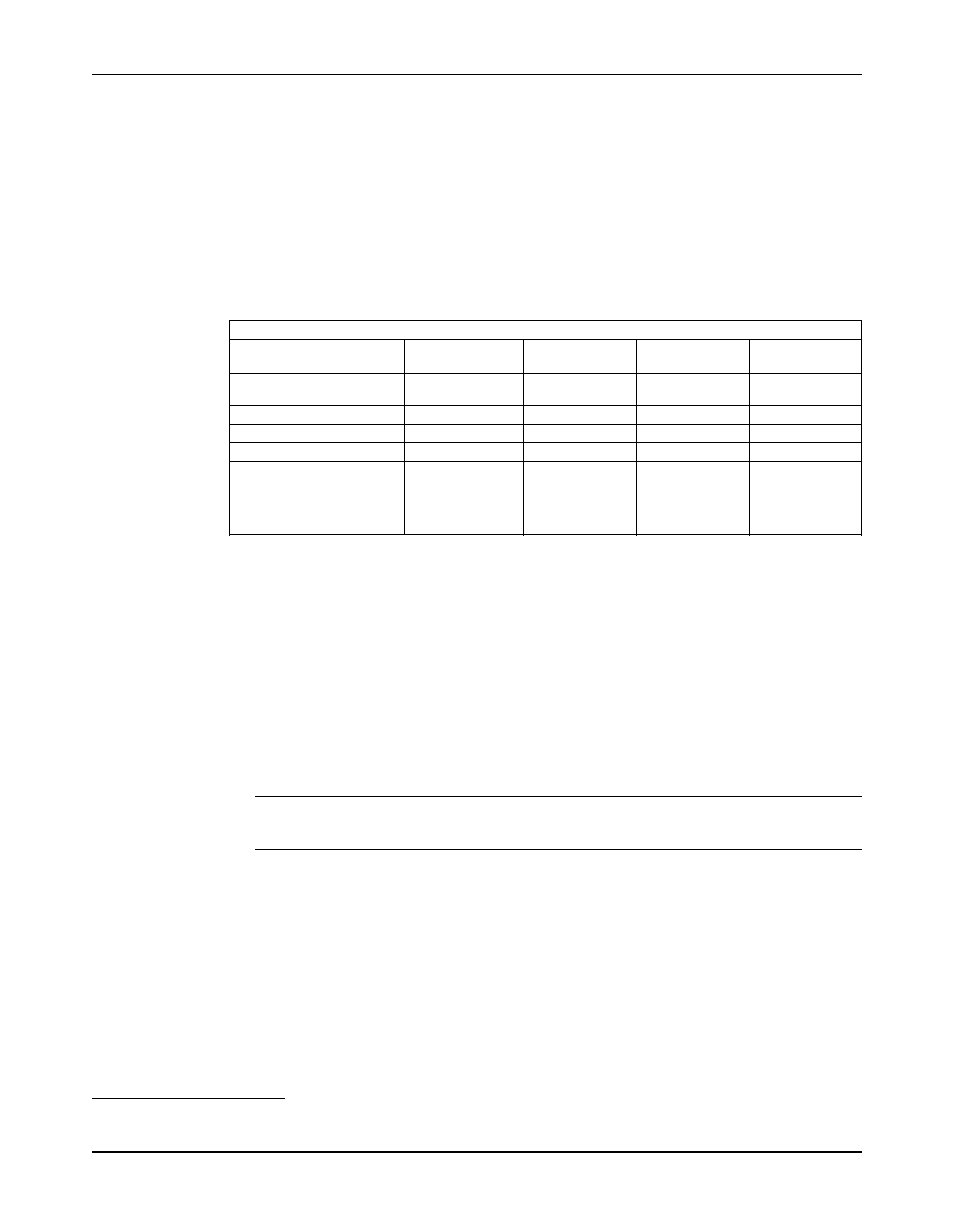

Oil volumes

This table shows the required amount of oil for oil-lubricated bearings.

Lubricating oil requirements

Quality requirements

Use a high quality turbine oil with rust and oxidation inhibitors.

See Lubricating Oil Requirements in "Maintenance of Bearings" for common names of some

acceptable lubricating oils.

3393 Ball Bearings

Pump size

2.5x4-8

4x5-10

5x6-11

6x8-13

2.5x5-8

4x6-10

5x8-11

6x10-13

Initial Fill per Bearing Hous-

3.4 / 1.6

3.4 / 1.6

5.3 / 2.5

5.3 / 2.5

ing - Oil (US pt, l)

Bearing - Driver End

7408 BCBM

7409 BCBM

7311 BECBM

7214 BECBM

Bearing - Outboard (ES)

1

SiC/SiC

SiC/SiC

SiC/SiC

SiC/SiC

Bearing - Outboard (RS)

6408

6409

6311

6214

Maximum permissible sur-

180 / 82

180 / 82

180 / 82

180 / 82

face temperature measured

at the 12 o'clock (top of

bearing housing) position.

(

O

F,

O

C)

Lubricate the bearings with oil

Flood oil-lubricated pumps are supplied with an oiler that maintains a constant oil level in the

bearing housing.

1. Fill the oil reservoir in the bearing frame:

a) Fill the bearing chamber through the main body of the Watchdog until it reaches the

optimum fluid level visible in the bullseye sight.

b) Fill the watchdog reservoir using a funnel.

c) Verify o-ring is on the Watchdog oiler spout.

d) Place your thumb over the reservoir spout. Invert and insert the spout into the internal

threaded boss on the main body.

e) Tighten reservoir. Do not over-tighten.

f)

Verify that proper oil level is maintained per the following diagram.

NOTICE:

Do not fill the oil reservoir of the bearing frame through the plug at the top.

1

Product lubricated bearing

40

Model 3393 Installation, Operation, and Maintenance Manual