Disassembly of suction end bearing, End suction pump - item 117 (sleeve bearing) – Goulds Pumps 3393 - IOM User Manual

Page 54

Maintenance

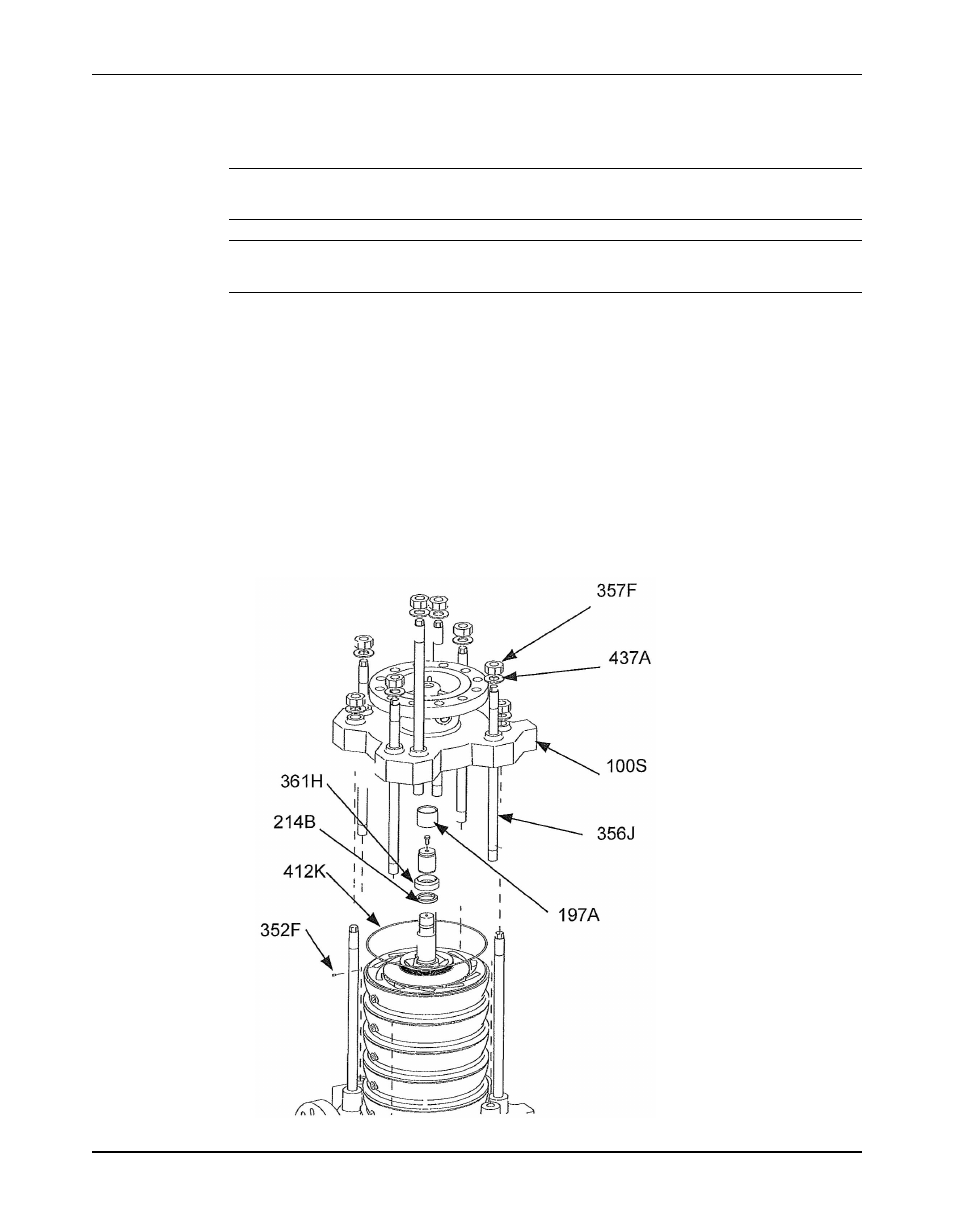

Disassembly of suction end bearing

End suction pump - item 117 (sleeve bearing)

See relevant sectional drawing

NOTICE:It is not recommended to remove the product lube bearing (197A) unless it is worn or

damaged.

NOTICE:Replacement of this bearing requires removal of the pump from the pipework and

baseplate.

1. Unbolt the pump from the piping system and baseplate.

2. Support the pump vertically with the suction casing uppermost.

3. Remove the balance line and any seal flush piping.

4. Remove the tie rod nuts (357F) and tie rod washers (437A) on the suction end of pump.

5. Remove suction casing (100S). Bearing 197A will be in the suction casing. Remove the o-

ring (412K).

6. Remove capscrew (469Y) and retaining plate (467).

7. Remove sleeve bearing (117) and tolerance rings (505D) from the end of the shaft.

8. Inspect the bearing sleeve for damage and check the clearance between the sleeve

bearing and the stationary bearing.

9. Unless the stationary bearing (197A) is worn or damaged it should not be removed from the

suction casing.

10. If necessary, remove stationary bearing (197A) from the suction casing being careful to

avoid damage to the casing..

52

Model 3393 Installation, Operation, and Maintenance Manual