Goulds Pumps 3393 - IOM User Manual

Page 60

Maintenance

4. Remove the bearings, following appropriate bearing removal instructions above depending

on seal location and pump configuration (item 409 and/or item 112).

5. Loosen the set screws holding the seal to the shaft.

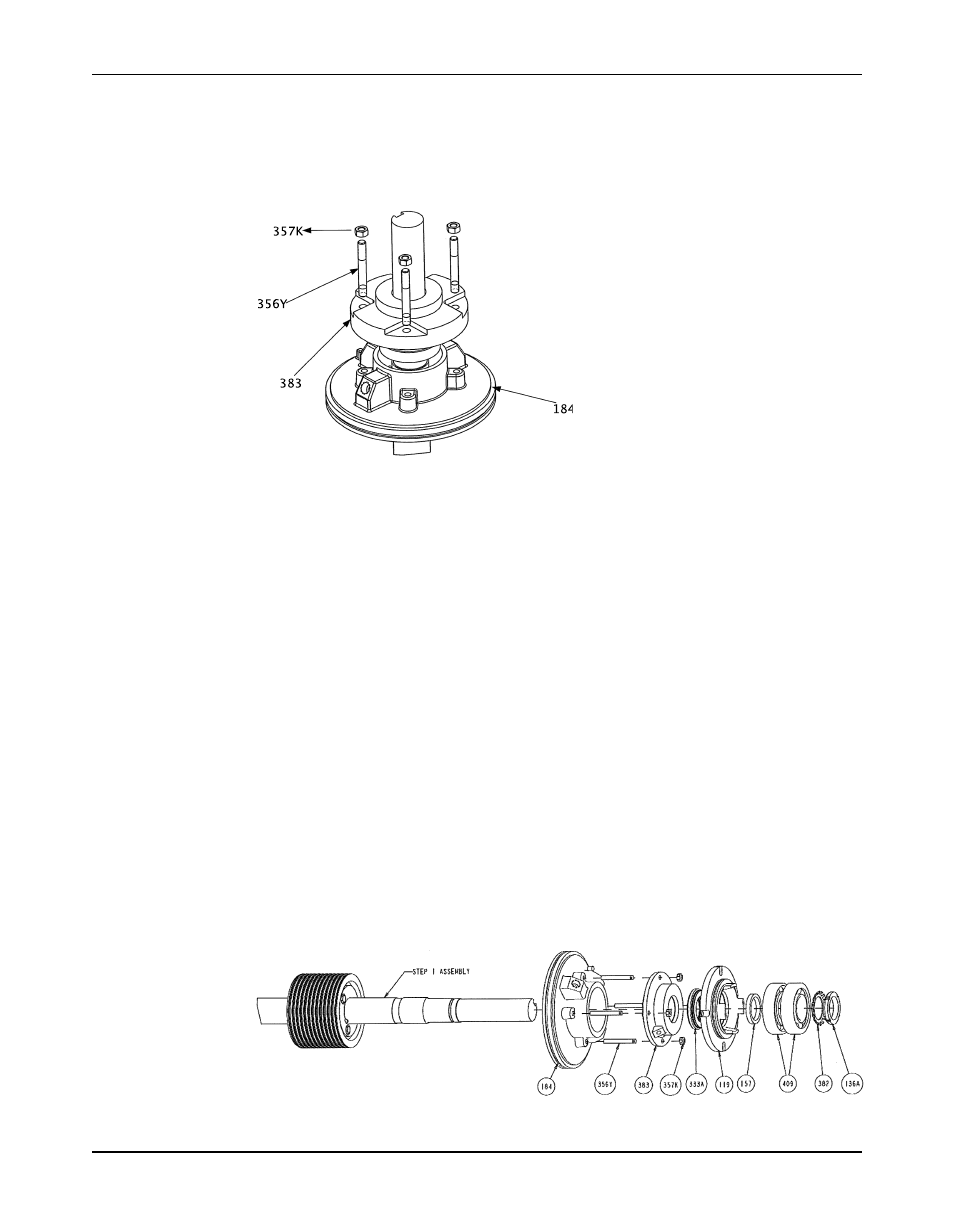

6. Remove nuts (357K) holding the mechanical seal (383) to the seal chamber housing (184).

7. Slide entire cartridge seal assembly over the shaft to remove it from the pump.

Disassembly of the balance drum rotor and stator - end and radial suction

pumps

1. Make sure that there is adequate access around the pump for inspection and maintenance.

Pump must be properly secured and stable before working on it.

2. Remove the thrust end bearing housing as noted in instructions for removal of the thrust

bearing (item 409).

3. Remove the mechanical seal and gland as noted in instructions for removal of the

mechanical seal.

4. Seal chamber (184) and seal chamber o-ring (412H) can now be removed from the

discharge casing (100D). Pull the housing toward the shaft end axially.

5. Remove the capscrews (372H) holding balance drum locking plate (519) to the balance

drum (300).

6. Remove balance drum locking plate (519) and balance drum locking plate key (178R).

7. Use a permanent marker to place an alignment mark on the shaft and balance drum.

8. Brace the shaft to prevent it from rotating. Insert threaded rods in the balance drum holes

and rotate the balance drum by 30º to clear the locking tabs on the shaft.

9. Remove balance drum and balance drum o-ring (412X) using the threaded rod. Do not

reuse balance drum o-ring.

10. Insert threaded rods into the balance drum stator and remove axially. Remove balance

drum stator (300A) and balance drum stator o-ring (496U). Do not reuse balance drum

stator o-ring.

11. Inspect visible portion of the shaft and remove any burrs or scratches with a file and emery

cloth.

58

Model 3393 Installation, Operation, and Maintenance Manual