Connection of sealing liquid for mechanical seals – Goulds Pumps 3393 - IOM User Manual

Page 44

Commissioning, Startup, Operation, and Shutdown

disengagement of the holding clips prior to operation, allowing the seal to slide into place. If the

seal has been installed in the pump by ITT, these clips have already been disengaged.

Connection of sealing liquid for mechanical seals

The mechanical seal must have an appropriate seal flush system. Failure to do so will

result in excess heat generation and seal failure.

Seal lubrication is required

Mechanical seals must have an appropriate seal flush system to avoid excessive heat

generation and premature seal failure.

Seal faces must have liquid film between them for proper lubrication. Locate the taps using the

illustrations shipped with the seal.

Seal flushing methods

You can use these methods in order to flush or cool the seal:

Method

Description

Product flush

Run the piping so that the pump pushes the pumped fluid from the casing and

injects it into the seal gland. If necessary, an external heat exchanger cools the

pumped fluid before it enters the seal gland.

External flush

Run the piping so that the pump injects a clean, cool, compatible liquid directly into

the seal gland. The pressure of the flushing liquid must be 5 to 15 psi (0.35 to 1.01

kg/cm

2

) greater than the seal chamber pressure. The injection rate must be 0.5 to

2 gpm (2 to 8 lpm).

Other

You can use other methods that employ multiple gland or seal chamber

connections. Refer to the mechanical seal reference drawing and piping diagrams.

Prime the pump with the suction supply above the pump

NOTICE:If temperatures of the pumped fluid will exceed 200°F (93°C), then warm up the pump

prior to operation. Refer to Warm Up Piping in the Auxiliary-piping checklist.

Pumps that are not self-priming must be fully primed at all times during operation.

1. Slowly open the suction isolation valve.

2. Open the air vents on the suction and discharge piping, the casing, the seal chamber, and

the seal piping, if provided, until all air is vented and only the pumped fluid flows out.

3. Close the air vents.

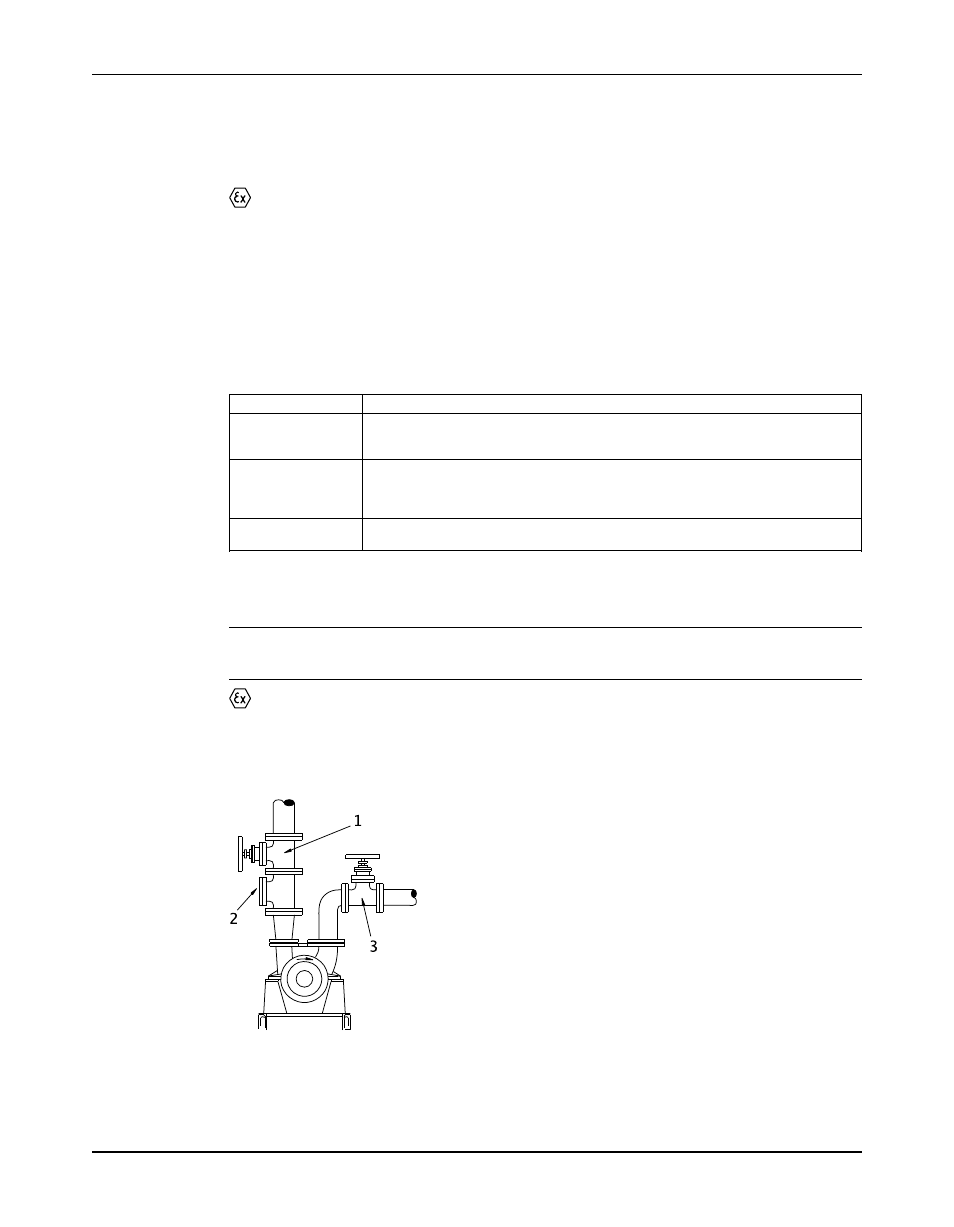

1. Discharge isolation valve

2. Check valve

3. Suction isolation valve

42

Model 3393 Installation, Operation, and Maintenance Manual