I-alert™ condition monitor routine operation – Goulds Pumps 3393 - IOM User Manual

Page 46

Commissioning, Startup, Operation, and Shutdown

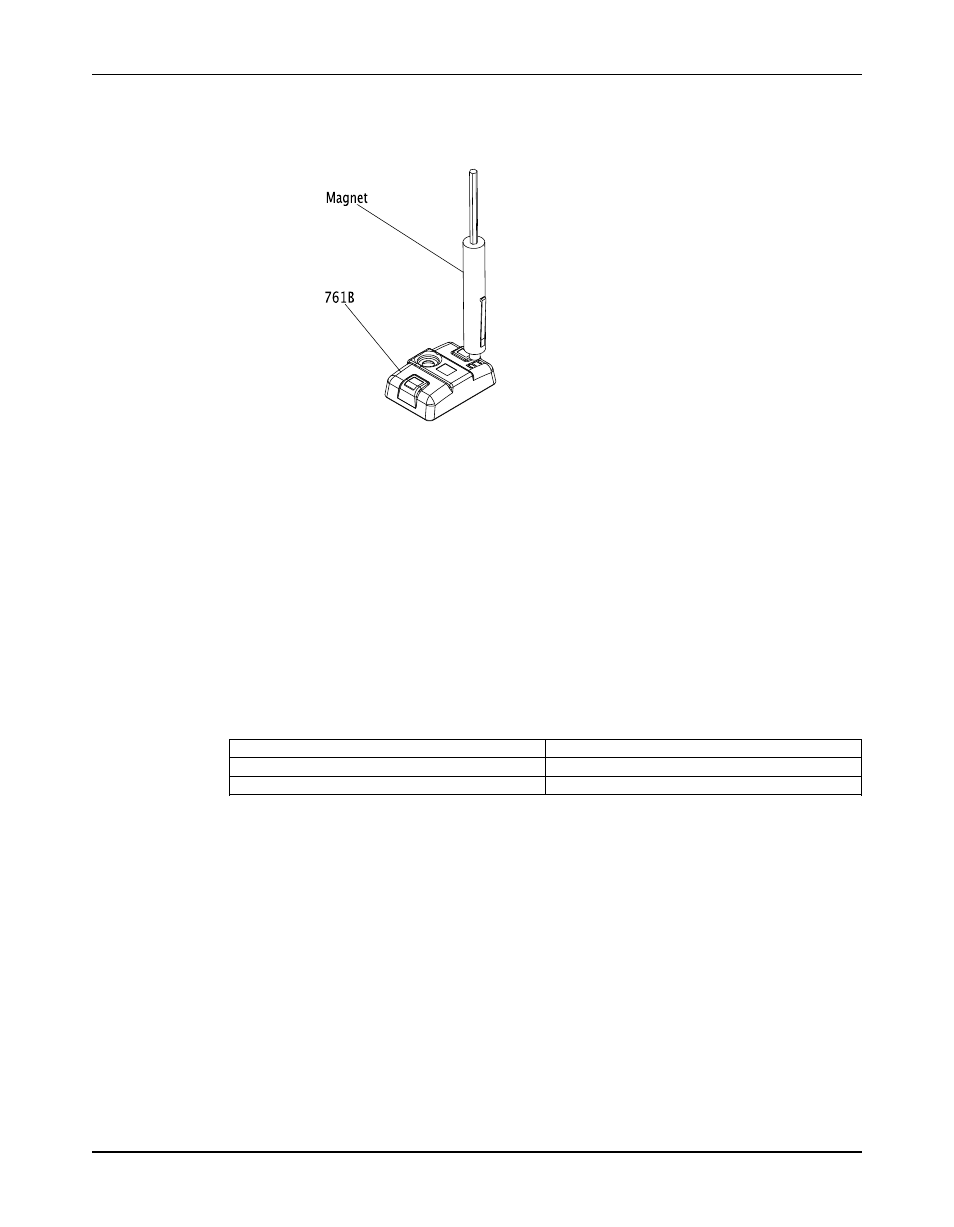

1. Place a small magnet on the condition monitor over the ITT logo and then remove it, as this

example shows.

When the condition monitor is activated it:

1. Displays a series of red LEDs followed by a solid green LED.

2. Collects eight samples that are spaced one second apart.

3. Averages these readings to establish the baseline vibration level.

4. Flashes a green LED after approximately twelve seconds.

For the first ten minutes, the green LED flashes every second for five consecutive flashes

and then pauses to take a vibration reading. More frequent measurements (every six

seconds) are taken in this startup period so that an alarm can be immediately detected.

i-ALERT™ Condition Monitor routine operation

Measurement interval

This table shows the measurement intervals for the condition monitor during normal operation and when

the monitor is in alarm mode.

Mode

Measurement interval

Normal operating mode

Five minutes

Alarm mode

Two minutes

When the condition monitor measures a reading beyond the specified temperature and

vibration limits, the appropriate red LED flashes. After the process or pump condition that

causes the alarm is corrected, the condition monitor returns to normal mode after one normal-

level measurement.

Alarm mode

When the condition monitor is in alarm mode, you should investigate the cause of the condition

and make necessary corrections in a timely manner.

Magnetic device considerations

Be careful when you use magnetic devices in close proximity of the condition monitor, such as

magnetic vibration-monitoring probes or dial indicators. These magnetic devices can acciden-

tally activate or deactivate the condition monitor resulting in improper alarm levels or loss of

monitoring.

44

Model 3393 Installation, Operation, and Maintenance Manual