Bearings inspection, Bearing-housing inspection, Bearings inspection bearing-housing inspection – Goulds Pumps 3196 i-FRAME - IOM User Manual

Page 93

Maintenance

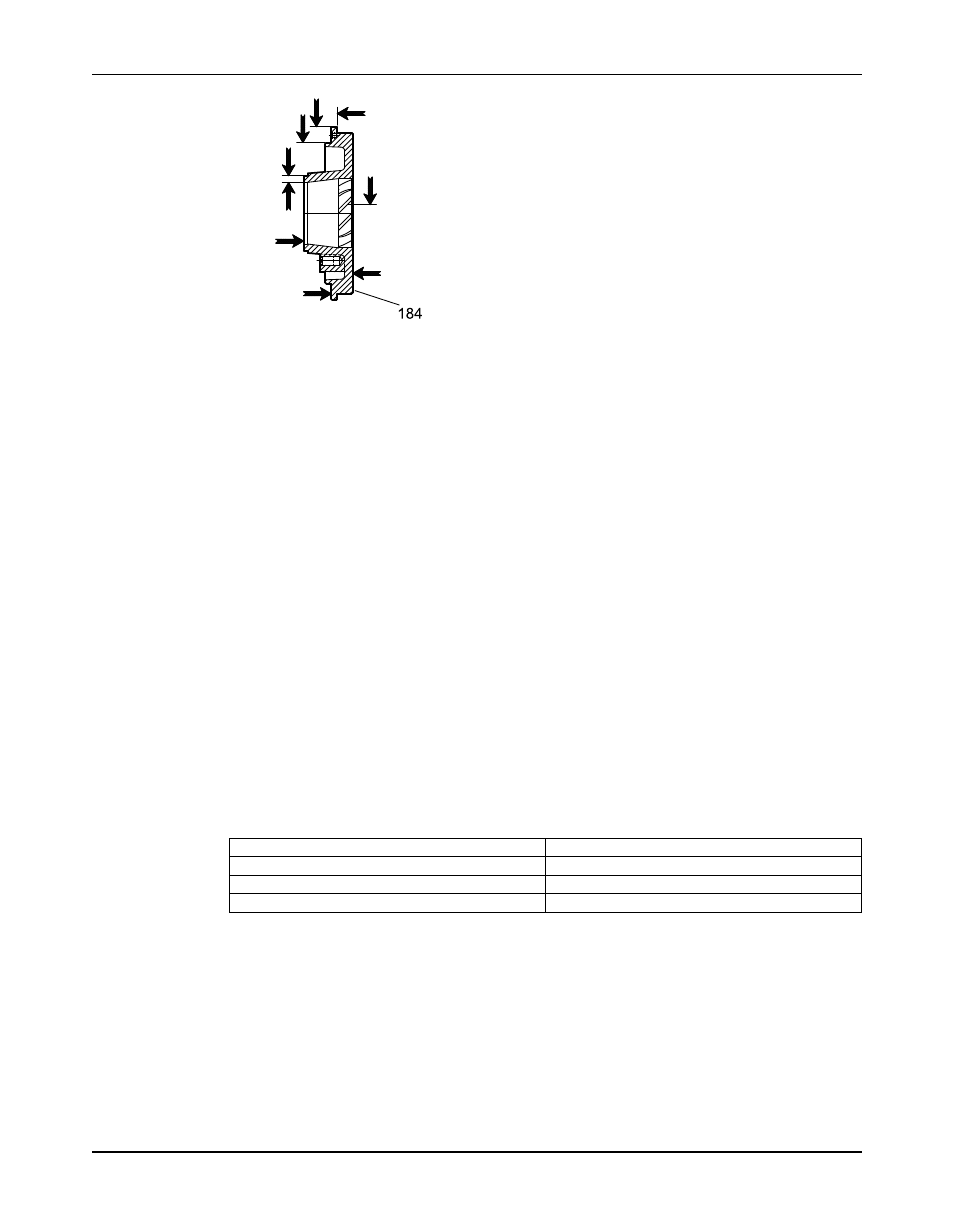

Figure 26: TaperBore

TM

Plus

Bearings inspection

Condition of bearings

Do not reuse bearings. The condition of the bearings provides useful information on operating

conditions in the bearing frame.

Checklist

Perform these checks when you inspect the bearings:

• Inspect the bearings for contamination and damage.

• Note any lubricant condition and residue.

• Inspect the ball bearings to see if they are loose, rough, or noisy when you rotate them.

• Investigate any bearing damage to determine the cause. If the cause is not normal wear,

correct the issue before you return the pump to service.

Bearing-housing inspection

Checklist

• Inspect the bearing-housing (134) bore according to the bearing fits and tolerances table.

• Replace the bearing housing if the dimensions exceed acceptable values. Reference: see

Bearings fits and tolerances.

• Visually inspect the bearing housing for cracks and pits.

Checklist for specific models

This table shows bearing-housing checks that are required for specific models of pump.

Frame

Bearing-housing check

STi and MTi

Ensure that the snap-ring groove is not cracked.

LTi

Clear all grooves and holes.

XLT-i and i17

Clean the gasket surface.

Inspection locations

The following images point to the areas to inspect on the bearing housing.

Model 3196 i-FRAME Installation, Operation, and Maintenance Manual

91