Lubricate the bearings after a shutdown period, Shaft seal maintenance, Mechanical-seal maintenance – Goulds Pumps 3196 i-FRAME - IOM User Manual

Page 66

Maintenance

Bearing temperature

Bearing temperatures are generally about 20°F (18°C) greater than bearing-housing outer surface

temperatures.

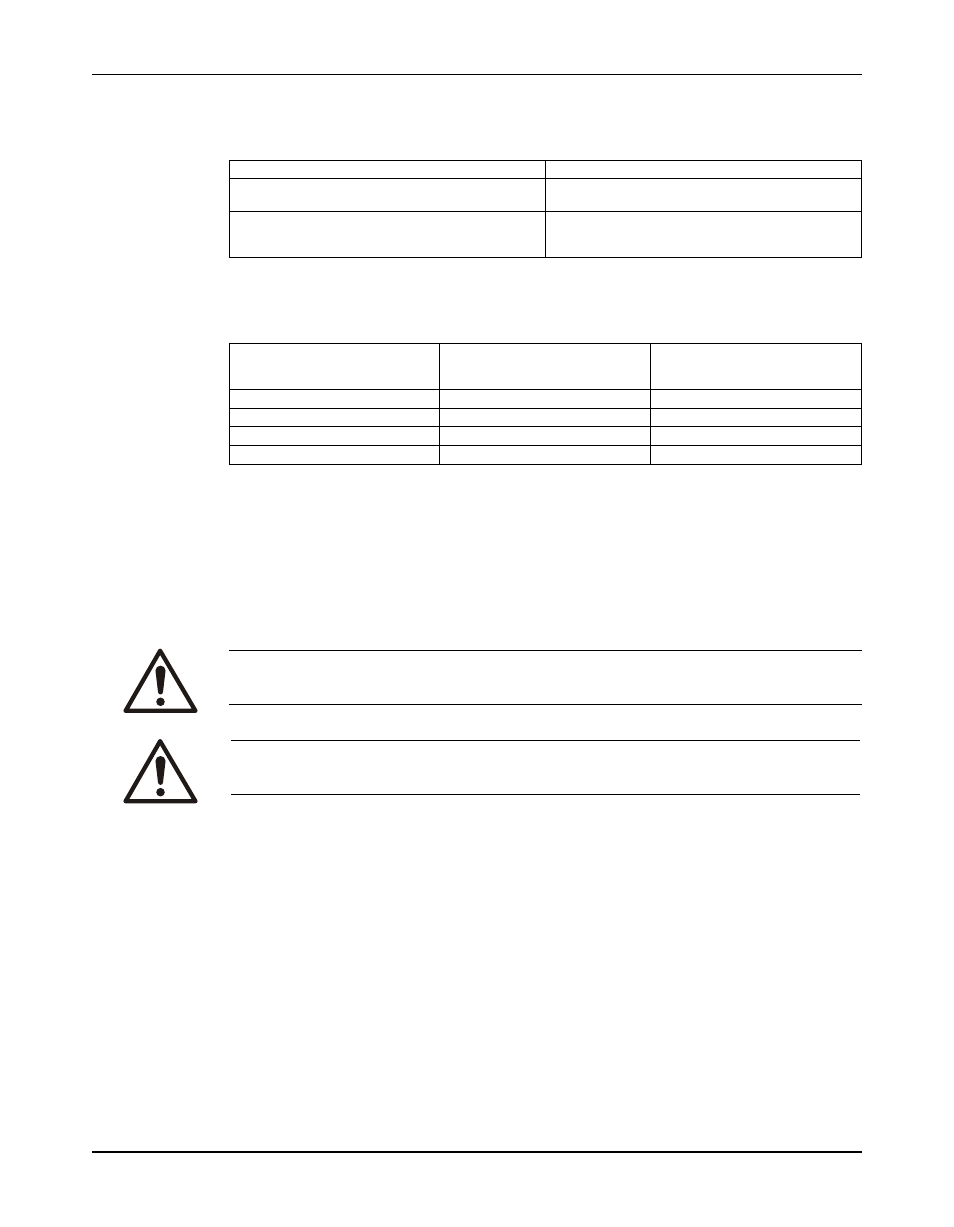

This table shows the type of grease required for the operating temperature of the pump.

Bearing temperature

Type of grease

5°F to 230°F (-15°C to 110°C)

Use a lithium-based mineral-oil grease with a con-

sistency of NLGI 2.

Exceed 350°F (177°C)

Use a high-temperature grease. Mineral-oil greases

should have oxidation stabilizers and a consistency

of NGLI 3.

Grease recommendations based on temperature

Most pumps use Sunoco 2EP grease. High temperature units that can pump fluids with a temperature

greater than 350°F (177°C) use Mobil SCH32.

This table shows which brand of grease to use when lubricating the pump.

Brand

When temperature of pumped

When temperature of pumped

fluid is less than 350°F

fluid is greater than350°F

(177°C) – NLGI consistency 2

(177°C) – NLGI consistency 3

Mobil

Mobilux EP2

SCH32

Exxon

Unirex N2

Unirex N3

Sunoco

Mutipurpose 2EP

N/A

SKF

LGMT 2

LGMT 3

Lubricate the bearings after a shutdown period

1. Flush out the bearings and bearing frame with a light oil to remove contaminants.

During flushing, make sure to rotate the shaft slowly by hand.

2. Flush the bearing housing with the proper lubricating oil to ensure oil quality after cleaning.

Shaft seal maintenance

Mechanical-seal maintenance

WARNING:

The mechanical seal used in an Ex-classified environment must be properly certified. Prior to startup,

make sure that all areas that could leak pumped fluid to the work environment are closed.

CAUTION:

Never operate the pump without liquid supplied to mechanical seal. If you run a mechanical seal dry,

even for a few seconds, this can cause seal damage. Physical injury can occur if a mechanical seal fails.

Reference drawing

The manufacturer supplies a reference drawing with the data package. Keep this drawing for

future use when you perform maintenance and seal adjustments. The seal drawing specifies

the required flush fluid and attachment points.

Before you start the pump

Check the seal and all flush piping.

Mechanical seal life

The life of a mechanical seal depends on the cleanliness of the pumped fluid. Due to the

diversity of operating conditions, it is not possible to give definite indications as to the life of a

mechanical seal.

64

Model 3196 i-FRAME Installation, Operation, and Maintenance Manual