Shaft and sleeve replacement guidelines – Goulds Pumps 3196 i-FRAME - IOM User Manual

Page 89

Maintenance

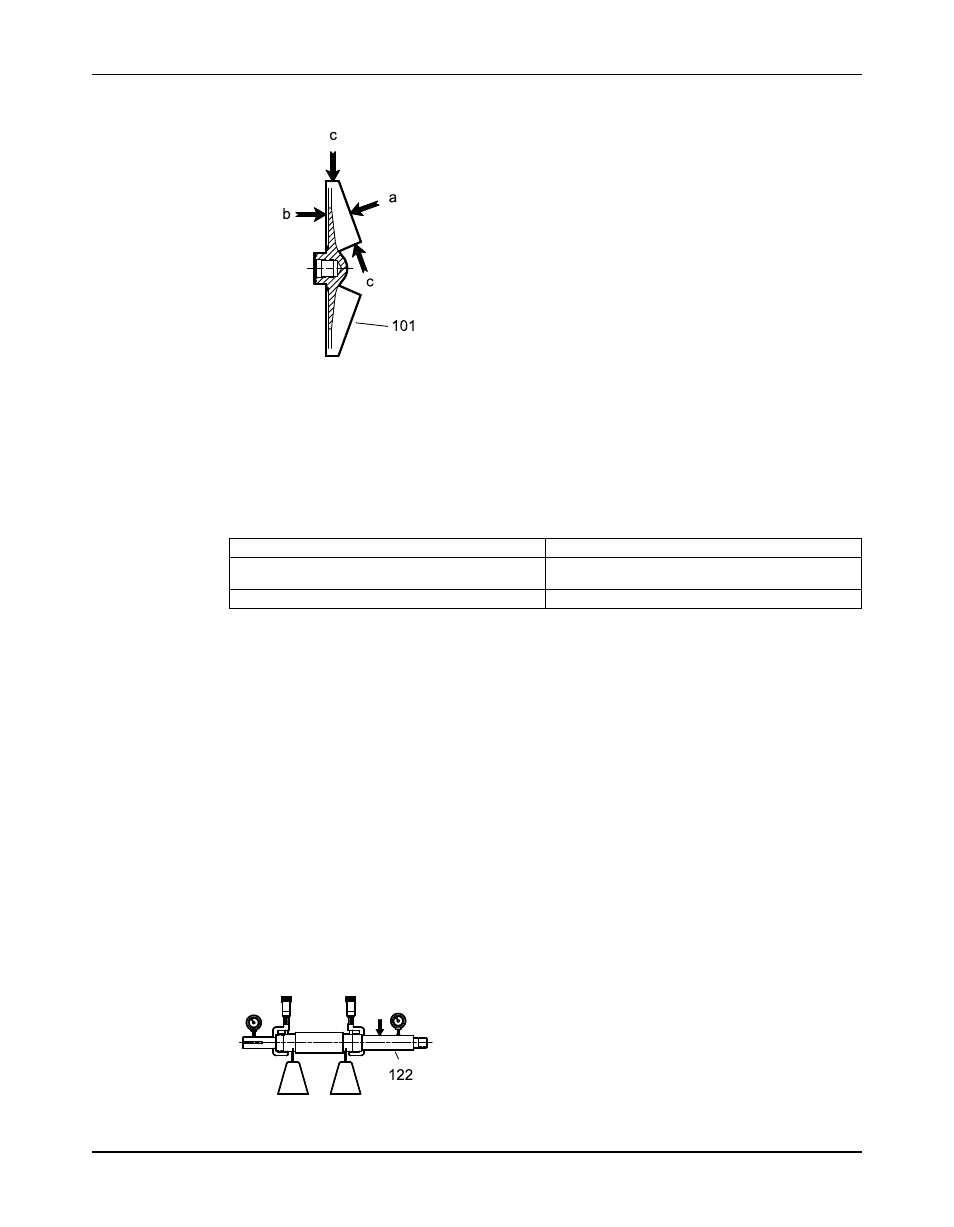

Impeller areas to inspect

Figure 19: Areas to inspect for wear on the 3196 impeller.

Frame adapter check and replacement

• Replace the frame adapter if it has cracks or excessive corrosion damage.

• Make sure the gasket surface is clean.

Dynamic-seal repeller replacement

This table shows the criteria for replacing dynamic-seal repeller parts for the 3196, CV 3196, and LF 3196

pump models.

Dynamic seal part

When to replace

Dynamic-seal repeller vane

The grooves are deeper than 1/16 in. (1.6 mm) or

are worn evenly more than 1/32 in. (0.8 mm).

Sleeve surface

The surface has grooves, pitting, or other damage.

Labyrinth seal replacement

Replace the labyrinth-seal O-ring if it has cuts and cracks.

Gaskets, O-rings, and seats replacement

• Replace all gaskets and O-rings at each overhaul and disassembly.

• Inspect the seats. They must be smooth and free of physical defects.

In order to repair worn seats, skin cut them in a lathe while you maintain dimensional

relationships with other surfaces.

• Replace parts if the seats are defective.

Shaft and sleeve replacement guidelines

Two types of sleeves

The 3198 is offered with either a metallic sleeve that uses the standard 3196 shaft or a Teflon

sleeve. The Teflon sleeve requires a special shaft and a different inboard labyrinth oil seal.

Shaft measurements check

Replace the shaft (122) if any measurements exceed acceptable values. See Bearing fits and

tolerances.

Model 3196 i-FRAME Installation, Operation, and Maintenance Manual

87