Install the coupling guard – Goulds Pumps 3196 i-FRAME - IOM User Manual

Page 48

Commissioning, Startup, Operation, and Shutdown

Install the coupling guard

WARNING:

• Never operate a pump without a properly installed coupling guard. Personal injury will occur if you

run the pump without a coupling guard.

• Always disconnect and lock out power to the driver before you perform any installation or

maintenance tasks. Failure to disconnect and lock out driver power will result in serious physical

injury.

• The coupling used in an Ex-classified environment must be properly certified and must be

constructed from a non-sparking material.

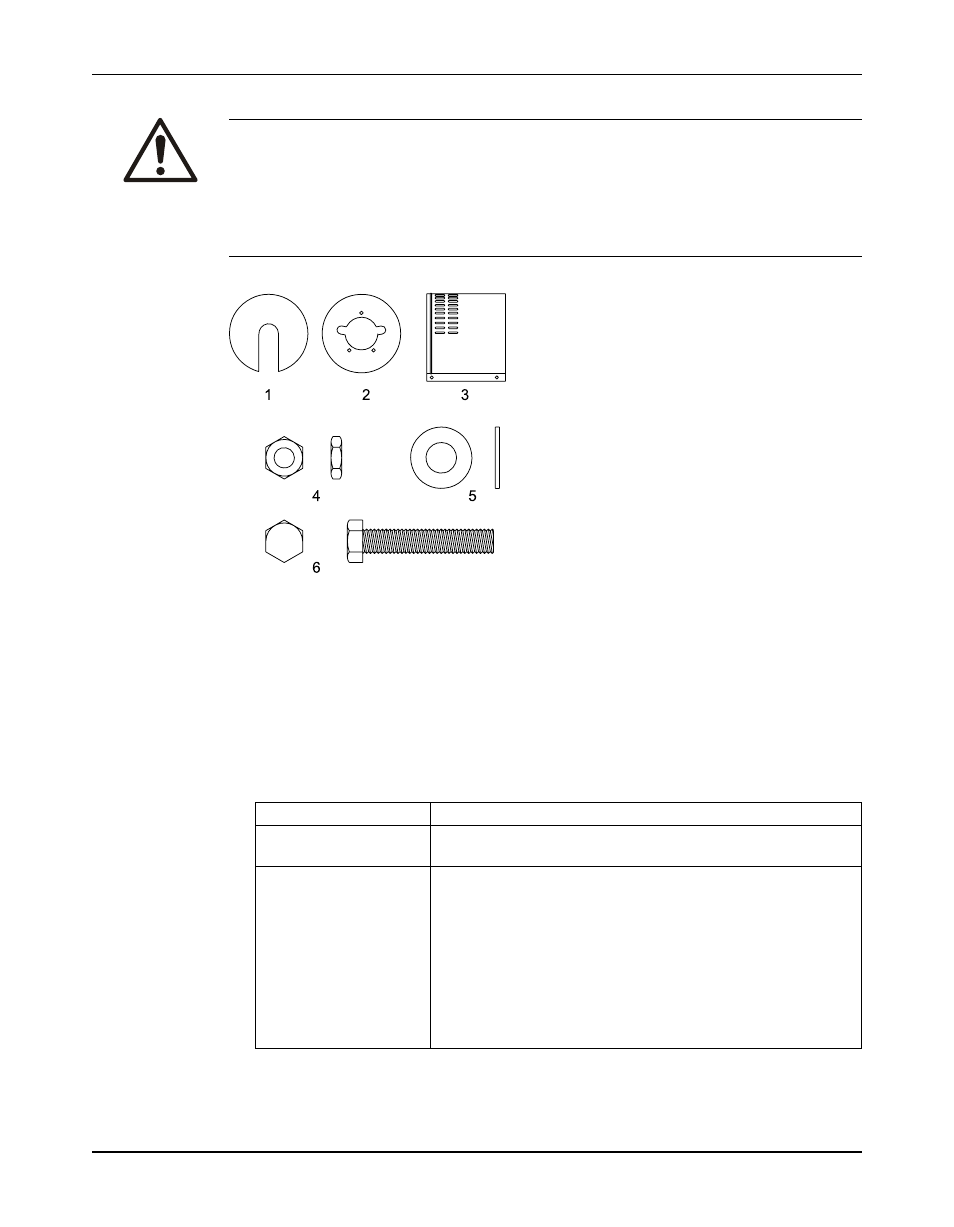

Required parts:

1. End plate, drive end

2. End plate, pump end

3. Guard half, 2 required

4. 3/8-16 nut, 3 required

5. 3/8 in. washer

6. 3/8-16 x 2 in. hex head bolt, 3 required

1. De-energize the motor, place the motor in a locked-out position, and place a caution tag at

the starter that indicates the disconnect.

2. Put the pump-side end plate in place.

If the pump-side end plate is already in place, make any necessary coupling adjustments

and then proceed to the next step.

If the pump size is...

Then...

STi, MTi, LTi

Align the pump-side end plate to the bearing frame. You do not

need to adjust the impeller.

XLT-i

1. Align the end plate on the pump side to the bearing housing

so that you meet these conditions:

1. The large slots on the end plate do not touch the bearing

housing tap bolts.

2. The small slots align with the impeller adjusting bolts.

2. Fasten the end plate to the bearing housing using the jam

nuts on the impeller adjusting bolts.

3. Check the impeller clearance. Refer to the impeller clear-

ance table for the correct impeller clearance.

46

Model 3196 i-FRAME Installation, Operation, and Maintenance Manual