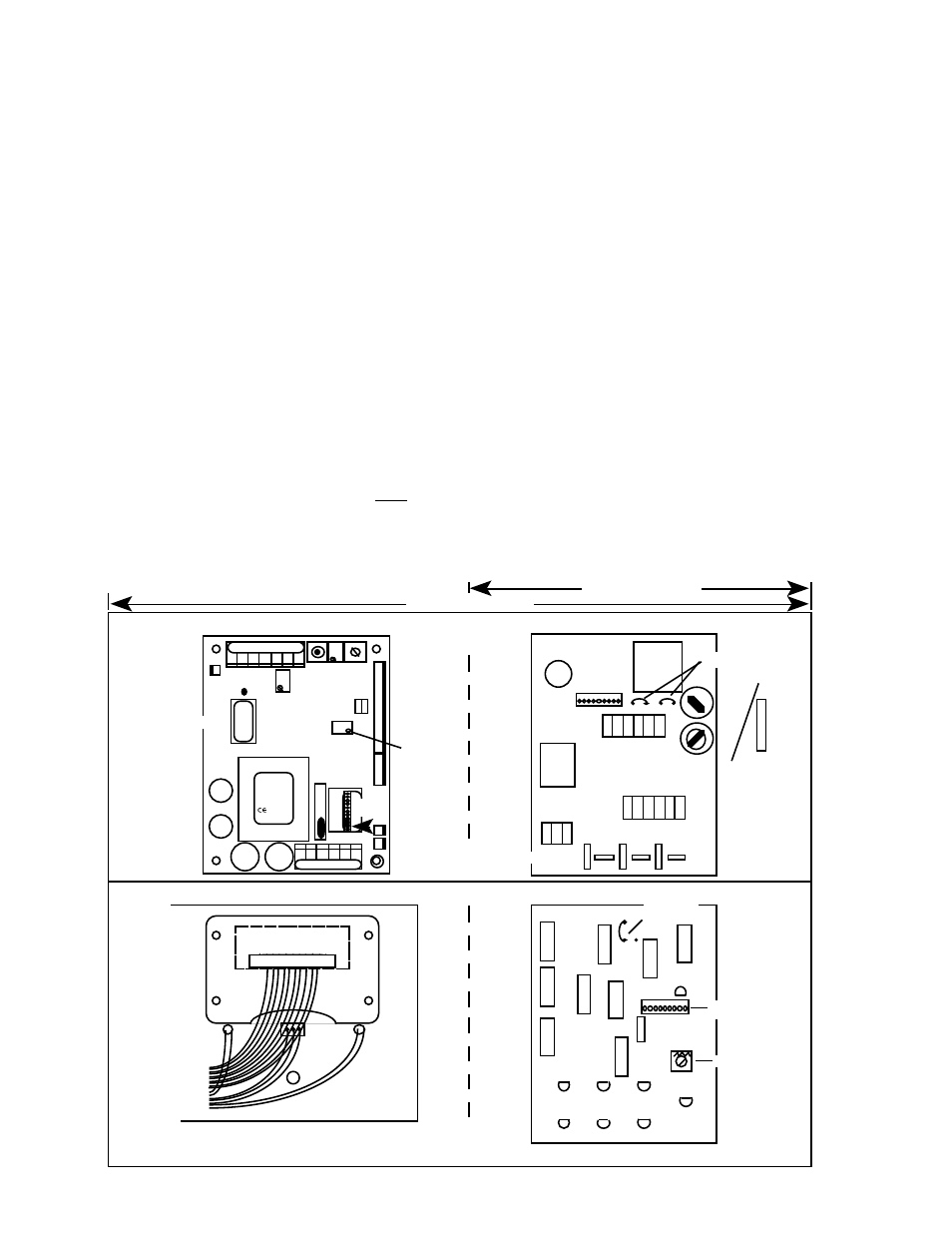

Figure v.a.1, Primary component identification – Myron L Aquaswitch II User Manual

Page 3

QUICK SET POINT ADJUSTMENT -

S e e S e c t i o n I V . B . 2 .

The set point setting is based upon the user's particular water

purity specifications or requirements.

1. While pressing the "SET POINT" switch, turn the Set

Point #1 adjustment screw (see figure V.A.1) until the

desired set point value is indicated on the display.

HYSTERESIS (DEAD BAND) ADJUSTMENT -

S e e S e c t i o n I V . B . 3 .

PRIMARY COMPONENT IDENTIFICATION -

Section V.A

.

Review the figure below to familiarize yourself with the different

circuit boards and component locations. The diagram has the

second alarm/control module option installed.

“PURGE CYCLE” CALIBRATION PROCEDURE

Section V.B.

“ALARM RESET” MODE CHANGE PROCEDURE

Section V.C.

QUICK CALIBRATION - Section V.D

.

WARNING: When performing calibration procedures,

the technician must take extreme care to avoid

contacting the circuitry other than the CALibration

control. Failure to do so could result in damage to

the equipment, property and/or personal injury.

The following assumes the front panel has been

removed and the power is ON.

ELECTRONIC CALIBRATION (CIRCUIT ONLY) -

S e e S e c t i o n V . D . 1 .

Full Scale Calibration V.D.1.a.

1.

Press and hold the Full Scale Test switch. The display

should indicate Full Scale for the particular range

selected, i.e. 0-20 M

Ω

should indicate 20. If not, set to

Full Scale with the CALibration control.

2.

Turn power O F F .

3.

Re-install front panel as described in “REASSEMBLY”.

4.

To operate, turn power ON.

10VDC Calibration - See Section V.D.1.b.

USING STANDARD SOLUTIONS - See Section V.D.2.

The BEST method of verifying and recalibrating your

conductivity/TDS

AQUASWITCH II

is with NIST traceable

Standard Solution (available from the Myron L Company).

Because it includes the sensor, the entire system is recalibrated.

NOTE: Since standard solution calibrations are NOT practicable

with resistivity models, another means of verification or

calibration of resistivity models is to use the transfer standard

method, using a hand-held or portable instrument capable of

resistivity measurements, such as the Myron L Ultrameter™. See

section V.C.4 for description.

SENSOR SUBSTITUTE CALIBRATION -

S e e S e c t i o n V . D . 3 .

TRANSFER STANDARD METHOD - See Section V.D.4.

21 may 03

Figure V.A.1

AQUASWITCH II

MAIN MONITOR/CONTROLLER BOARD

E

N

C

L

O

S

U

R

E

PRIMARY COMPONENT IDENTIFICATION

AQUASWITCH II

AQUASWITCH I

AQUASWITCH

LOGIC BOARD

F

R

O

N

T

P

A

N

E

L

LOW

DISPLAY

HARNESS

DISPLAY

DISPLAY CONNECTOR

RED

GREEN

SET POINT

SWITCH

TO MONITOR/

CONTROLLER

CIRCUIT BOARD

DISPLAY

CONNECTOR

AQUASWITCH II

DIGITAL DISPLAY

CABLE

CONNECTS TO

POWER BOARD

PURGE CYCLE

CONTROL

AQUASWITCH

POWER BOARD

TRANSFORMER

FUSE*

115/230

SWITCH

AQUASWITCH™

POWER BOARD

NC

NO

COM

GRD

C

AC

NO

COM

NC

FUSE

1/8 Amp

AGC 1/8

BK B

BK A

BLD

COM

LOGIC

BOARD

CONNECTION

RELAY

115/230

JUMPERS

OR

ALARM OUTPUT

CONNECTORS

*115/230VAC

FUSE

100mA

(T.10A) 5X20

Slow Blow/

Time Delay

*24 VAC/24 VDC

FUSE

250mA

(T.25A) 5X20

Slow Blow/

Time Delay

TRANSFORMER

FUSE*

1 1 5 /

230

751 756

752 757

753 758

754 759

HYS1

SP1

FS SW

DIS

INC

DEC

CAL

-11

0-20m

Ω

UP

}

3S

SPC

CALIBRATION

CONTROL

DISPLAY

HARNESS

CONNECTOR

DISPLAY

CALIBRATION

CONTROL

RANGE

MODULE

4-20

CONNECTOR

BK WT RD GN NU R- R+

REMOVE TO

INSTALL

SECOND

RELAY

PWR C GD NC NO CM

BK B

WHT

STANDARD

ALARM RESET

ENABLE JUMPER

MYRON L

COMPANY