Polyfeeder controller principles of operation, 4 system controller options, 1 b and b++ series automated control – Pulsafeeder Polyfeeder EN User Manual

Page 6: 1 manual, 2 remote

6

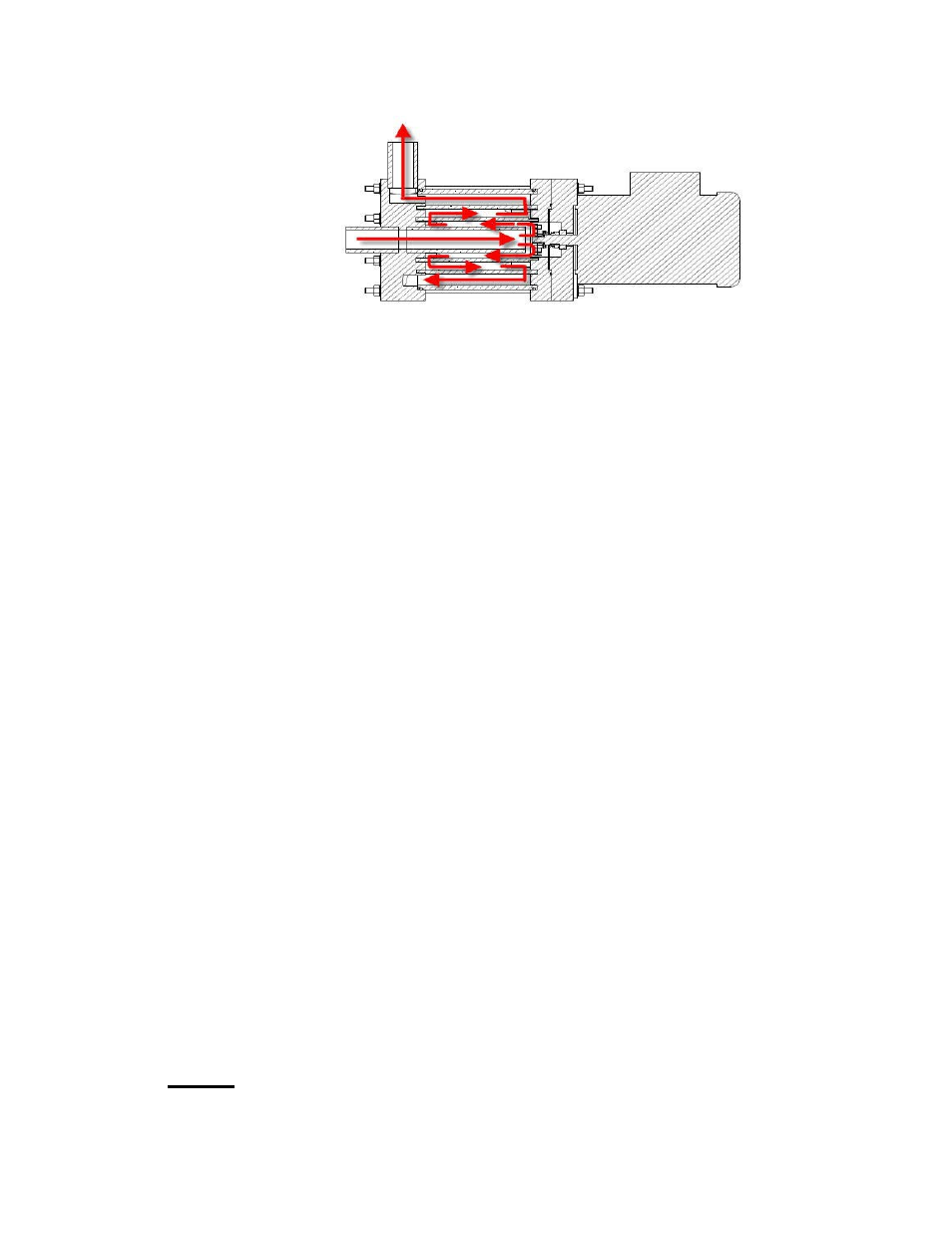

Figure 2-3 Polymer Mixing Chamber

2.4 System

Controller

options

2.4.1 Manual

The simplest option for small systems: make down on/off controlled at the system, polymer blend

concentration adjusted manually via neat polymer pump control, dilution water adjusted with globe

valves.

Once setup and calibrated, the system operates continuously supplying a constant flow of emulsified

polymer solution at the desired concentration. Users must monitor the supply of neat polymer solution

and refill the tank or change the tote as necessary. Water flow rate is indicated on the on-board

rotometers.

2.4.2 Remote

A step up to control from an outside source: accepts a remote 4-20 mA signal to control polymer make-

down concentration. Remote systems still permit manual operation, as described above. For remote

operation, the system accepts a remote START/STOP (dry) contact closure, as well as a 4-20 mA loop

signal. The loop signal controls the flow rate of the neat polymer feed pump and therefore the

concentration of the finished polymer solution. Water flow rate, once set, remains constant.

3. PolyFeeder Controller Principles of Operation

Pulsafeeder Polyfeeder systems come in two general control categories:

Manual (see Manual Polyfeeder IOM Publication)

B and B++ series

Your Polyfeeder polymer mixing system will control polymer make down chamber and final

solution concentrations either manually or automatically by controlling the ratio of polymer to

primary and secondary water dilution streams.

3.1 B and B++ Series Automated Control

B-Series

B Series automatic control allows the user to set a known solution concentration after manually

configuring the primary and secondary (total system) water flows. Once both water flows are