Pulsafeeder Polyfeeder EN User Manual

Page 26

26

6.7.2.2 Operating the Polymer Mixing System

6.7.2.2.1 Starting/Stopping the Polymer Mixing System

The Polymer Mixing system has a fully programmable start up and shutdown sequence. System delays

may be put into the system to provide for system start lags and system self flushing timings.

the system components simultaneously by placing the operational mode switch into the pump off

position.

6.7.2.2.2 Starting the Polymer Mixing System

The polymer start sequence is initiated by pushing the “SYSTEM START/STOP” button (local control

mode) or upon closure of the remote start/stop contact (remote control mode). Upon receiving either

signal, the system will proceed through a fixed series of actions with programmable delays. The startup

sequence provided by the controller is as follows:

1. The water valve, supplying primary and secondary dilution, is opened providing system

flow. The system then looks for primary water flow to occur via flow sensor or flow switch.

If no flow, the system shuts down.

2. Waits a user adjustable delay Water on time (0-255) seconds

3. Starts the mixing chamber AC motor/impeller.

4. Waits a adjustable mixer on delay time (0-255) seconds

5. Starts the polymer delivery pump.

6. Waits for an “Alarm Delay” time where alarms are ignored until the time elapses.

7. Proceeds to “RUN” status, displaying the current polymer flow setpoint and water flow set

point.

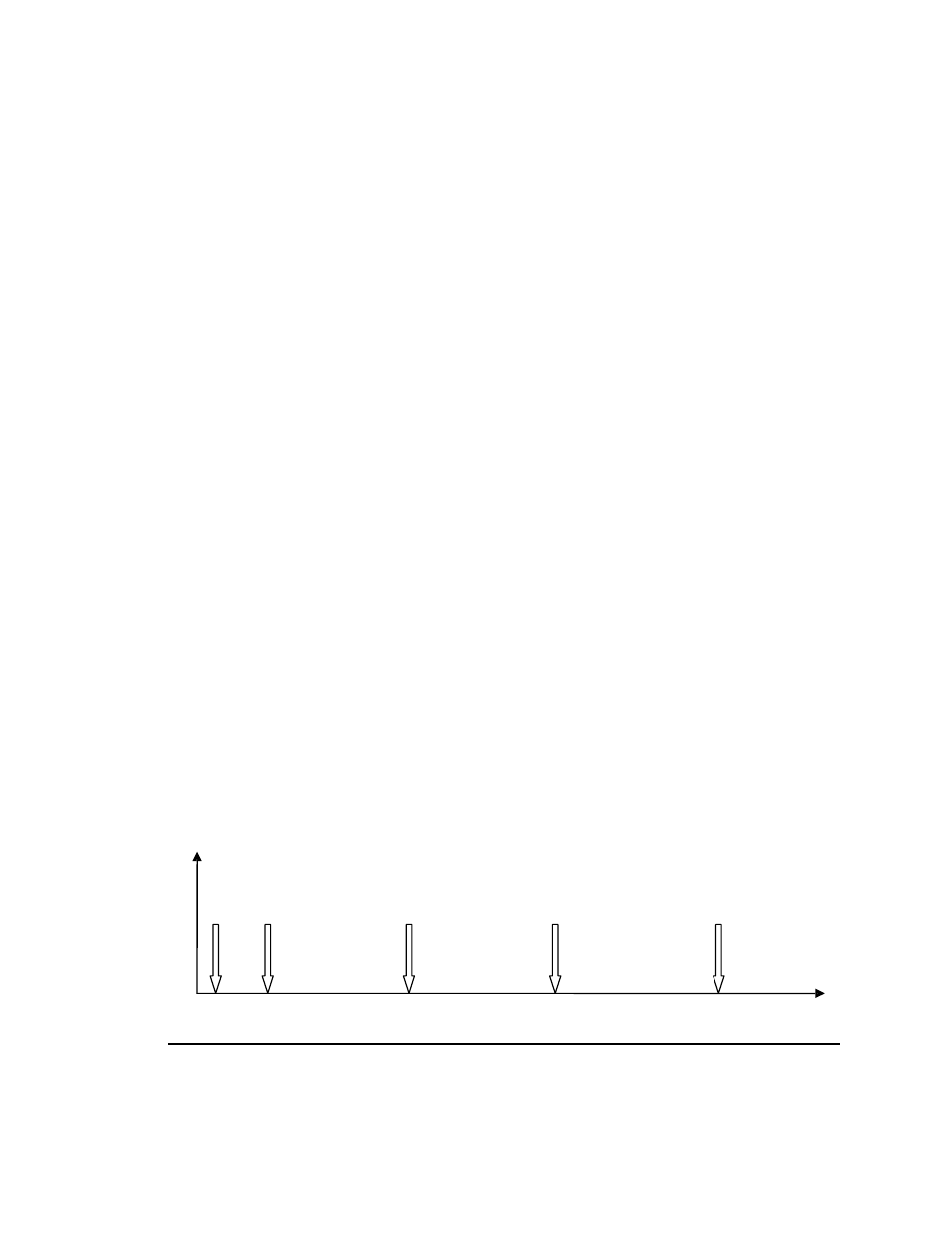

The start-up sequence can be pictorially represented as:

System

Start

Water Valve

Opened

Water

Running

?

Water on

Delay Time

Mixer

Motor/Impeller

Energized

Mixer on

Delay Time

Polymer Pump

Energized

Alarms

Activated

Delay Time

System

Running

Time (seconds)

Figure 6-7-2-2-2 START UP SEQUENCE--POLYMER MIXING SYSTEM