Specifications, Materials reference – Pulsafeeder Polyfeeder EN User Manual

Page 44

44

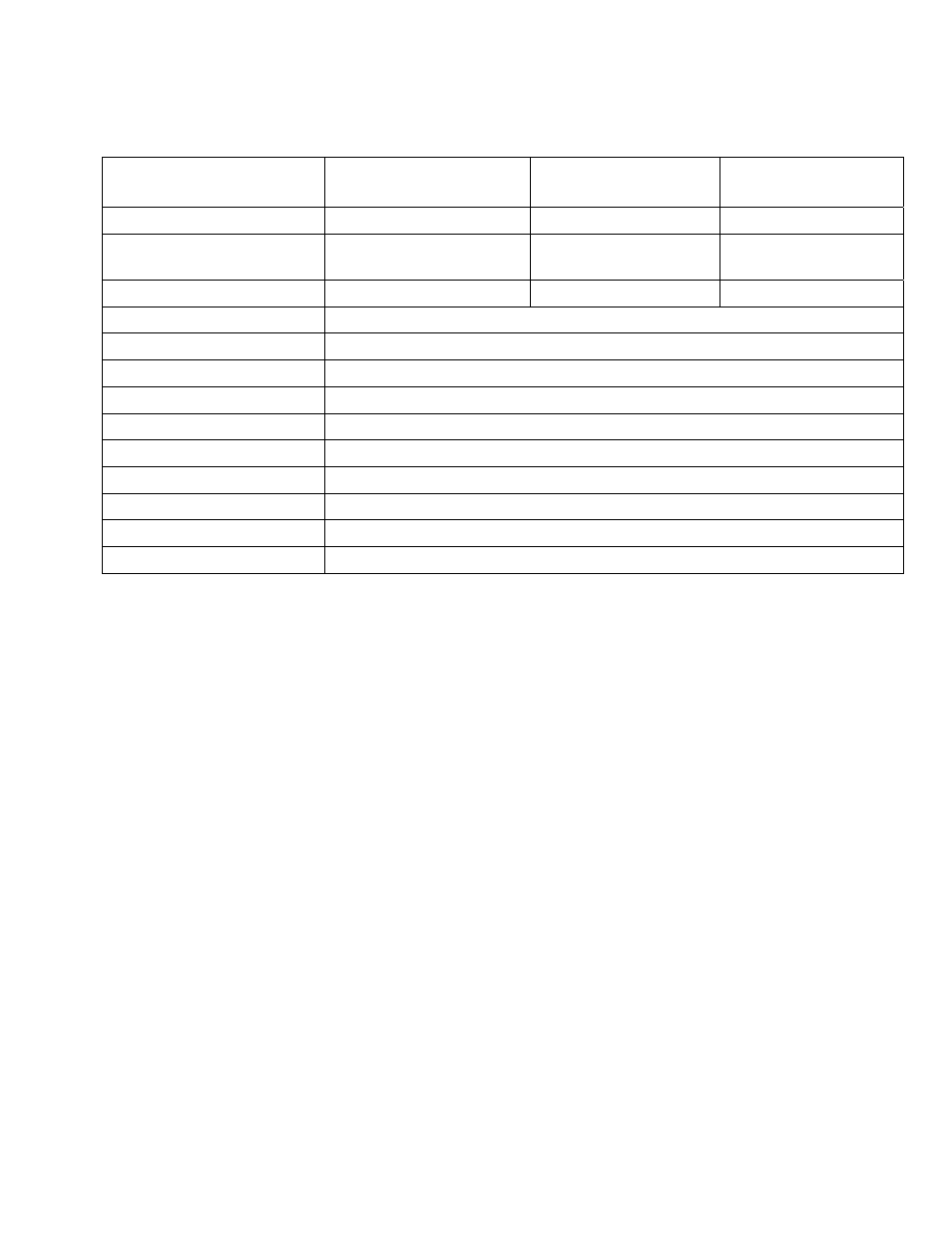

10. Specifications

Neat Polymer Feed:

Solenoid

Neat Polymer Feed:

Progressive Cavity

Neat Polymer Feed:

Gear Pump

Maximum Neat Flow Rate

10 gph 56

gph 56

gph

Maximum Dilution Water

Rate

30 GPM

120 GPM

120 GPM

Control Options (see below)

Manual/Remote/Auto Re

mote/Auto

Remote/Auto

Materials of Construction

PVC and 300 series stainless steel (all frames are stainless steel)

Input Voltage

115 VAC standard, 230 VAC optional, 50 or 60 Hz

Current Requirement

20 A @ 115 VAC, 10 A @ 230 VAC

Basic Dimensions

Width 36 - 40”; Depth 24”; Height 60 - 68”

(model dependent)

Neat Polymer Inlet

0.5” MNPT

Dilution Water Inlet

Neat polymer feed rates up to 3 gph, 1.0” FNPT

Neat polymer feed rates 3 gph to 21 gph, 1.5” FNPT

Neat polymer feed rates above 21 gph, 2.0” FNPT

Solution Outlet

MNPT, follows same sizing as above inlet fittings

Environment Rating

Controls: NEMA 4X, Motors: TEFC

11. Materials Reference

All materials in contact with liquids in the system are as follows:

300 series stainless steel

PVC

Clear PVC

Mix Chamber O-rings are BUNA -N

Union elastomers are Viton

Mix Chamber motor shaft seal is carbon vs. ceramic w/ Viton elastomers

Refer to polymer feed pump manual for materials of construction

Rotameters are clear acrylic, polypropylene, 316 stainless steel and Viton

Ball cone checks are PVC/Viton