Pulsafeeder Polyfeeder EN User Manual

Page 12

12

6.5 CONNECTING,

PRIMING,

AND

CALIBRATING

THE

POLYFEEDER SYSTEM

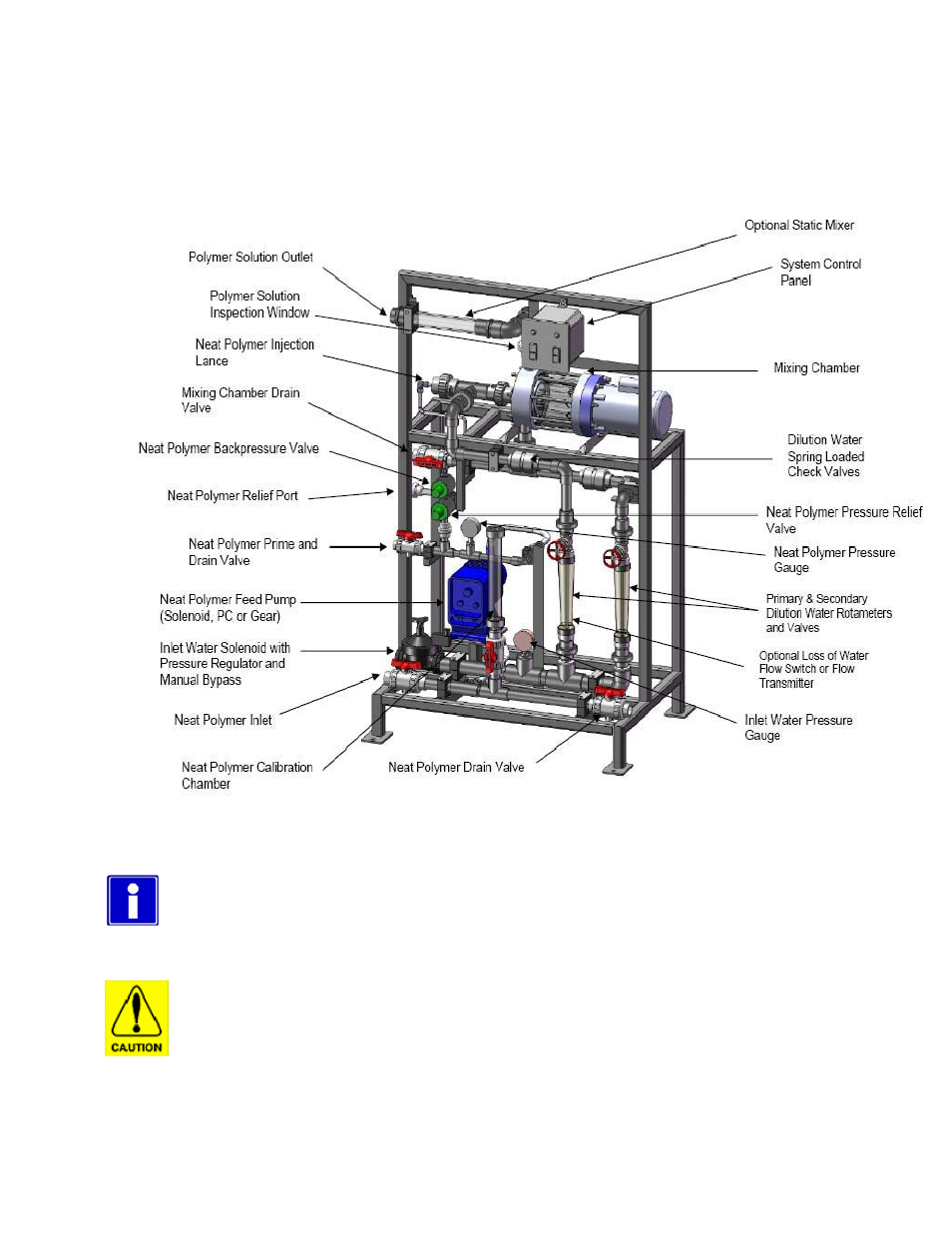

Figure 6-5 Polyfeeder(Solenoid Version) Showing Process Connection and Valving

NOTE: Do not run the system dry for any length of time as this will cause excessive wear of the

polymer feed pump components and the Mixing chamber motor shaft seal. Momentary operation

to verify power and shaft rotation is acceptable.

CAUTION! The Mixing chamber is rated for 150 PSI. Do not exceed this pressure – operation of

the unit at pressures greater than 150 psi can cause injury or equipment damage.

See also other documents in the category Pulsafeeder Pumps:

- Pulsa GLM DM1-6 (30 pages)

- Pulsa GLM DM7 (33 pages)

- Pulsa 340 (24 pages)

- Pulsa Series 200-680C (20 pages)

- Pulsa Series 680 EN (26 pages)

- Pulsar 25H (54 pages)

- Pulsar Shadow (48 pages)

- PulsaPro 900 EN (71 pages)

- PULSAlarm (24 pages)

- Eclipse Hypopump (140 pages)

- ECO Series Back Pressure Valve Instructions (1 page)

- ECO Series Relief Valve Instructions (1 page)

- Isochem RGT IOM (44 pages)

- Pulsar Series HypoPump (15 pages)

- Pulsar Series HypoPump2 (27 pages)

- MPC (56 pages)

- MPC Vector (70 pages)

- Pulsa Series Pulsamatic Controls (34 pages)

- Pulsar DLC (120 pages)

- Pulsar DLC XP RC (68 pages)

- Pulsar DLCM (135 pages)

- Pulsar ECA NEMA4X (38 pages)

- Pulsar ECA NEMA7 (23 pages)

- Chem-Tech Series XPV EN (19 pages)

- Chem-Tech Series XP EN (22 pages)

- Chem-Tech Series XP TIMER EN (20 pages)

- Chem-Tech Series Prime Performance EN (12 pages)

- Chem-Tech Series Prime Performance EN (3 pages)

- MEC-O-MATIC VSP Series (8 pages)

- OMNI Series DC7 (34 pages)

- OMNI Series DC2-6 EN (46 pages)

- PULSAtron Series A Plus EN (16 pages)

- PULSAtron Series ET (17 pages)

- PULSAtron Series MP EN (32 pages)

- PULSAtron Series T7 (23 pages)

- Digital Glycol Feeder DGF1 (45 pages)

- Polymer Makedown Automatic Systems EN (15 pages)

- Polymer Makedown Systems EN (11 pages)

- Pre-Engineered Skid Systems (23 pages)